Marker speed, Dual-circuit/needle valve speed, Single-circuit/sequence valve speed – Great Plains 2525F Operator Manual User Manual

Page 31

Adjustments 27

01/23/2012

118-232M

Marker Speed

The procedure for adjusting marker speed is different for

dual-circuit markers with needle valves and single-circuit

markers with dual sequence valve.

Dual-Circuit/Needle Valve Speed

This applies only to markers plumbed separately (left

and right are each on their own tractor hydraulic circuit).

Refer to Figure 25

A needle valve controls the folding speed. The needle

valve is near the rod end of the marker cylinder.

With tractor idling at a normal operating speed, adjust

marker folding to a safe speed. Turn adjustment knob

clockwise to reduce folding speed or counterclockwise to

increase folding speed. Excessive folding speed could

damage markers and void the warranty.

FigureSpacer

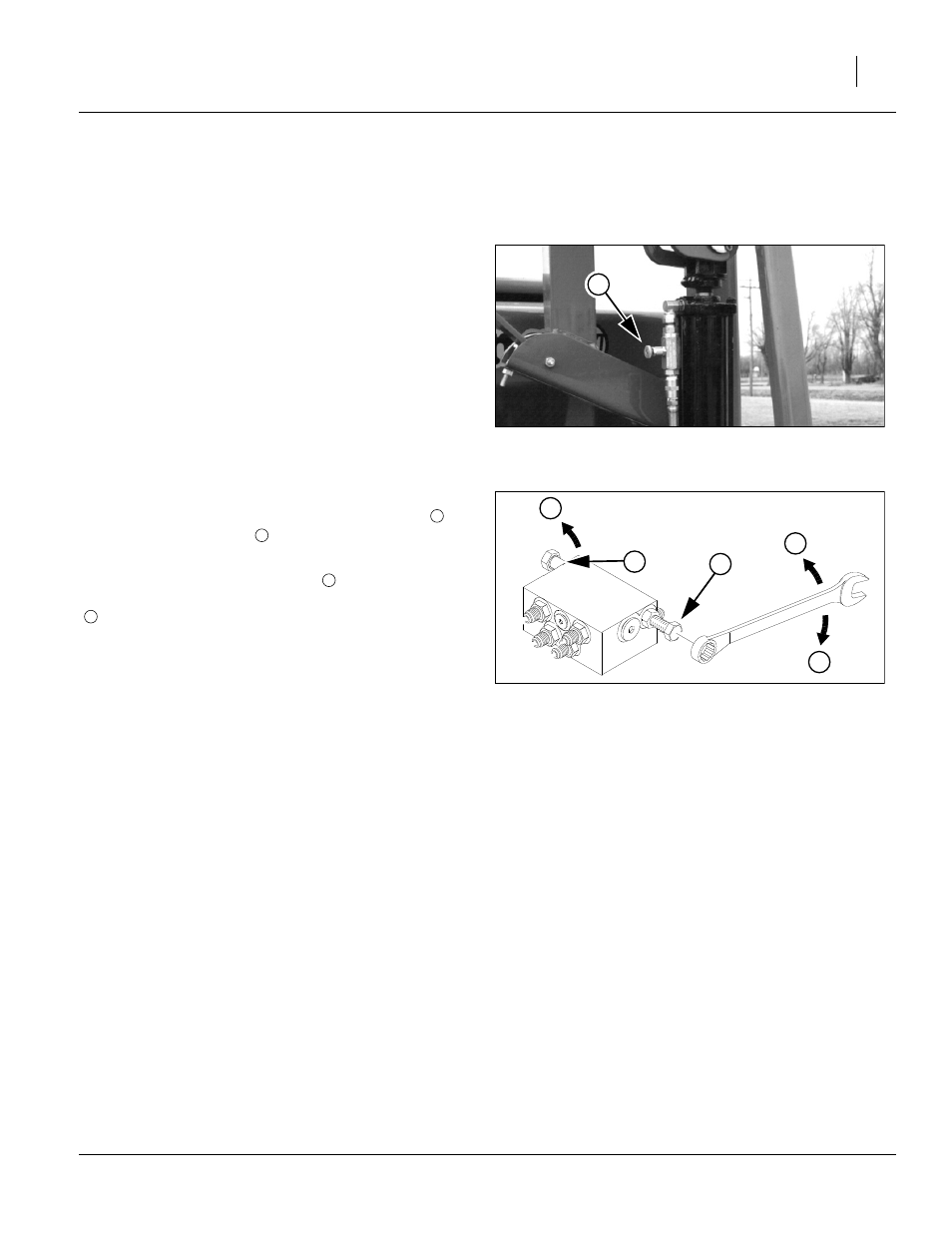

Single-Circuit/Sequence Valve Speed

There is one adjustment screw for unfolding speed

and one for folding speed

. You can identify adjustment

screws by markings stamped in valve body.

Turn adjustment screws clockwise (

: slower) to

decrease [un]folding speed and counterclockwise

(

: faster) to increase [un]folding speed.

With tractor idling at a normal operating speed, adjust

marker folding to a safe speed. Excessive [un]folding

speed could damage markers and void the warranty.

After adjusting the folding speed, tighten jam nuts on hex

adjustment screws to hold settings.

FigureSpacer

Figure 25

Needle valve Adjustment

17620

1

1

2

F

S

S

Figure 26

Sequence Valve Adjustment

14048

1

2

S

F