Maintenance and lubrication, Maintenance, Storage – Great Plains SS0300 Operator Manual User Manual

Page 25

09/19/2011

596-224M

Great Plains Manufacturing, Inc.

21

Maintenance and Lubrication

Maintenance

1.

Proper servicing and maintenance is the key to long

implement life. With careful and systematic inspection,

you can avoid costly maintenance, downtime and

repair.

2.

Always turn off and remove the tractor key before mak-

ing any adjustments or performing any maintenance

After using the implement for several hours, check all

bolts to be sure they are tight.

4.

After one hour and again after five hours re-torque the

grade 8 bolts (1) to 400 FT LBS. Re-torque periodically.

5.

Lubricate areas listed under “Lubrication”, page 22.

6.

Inflate tires as specified on “Tire Inflation Chart”, page

25.

7.

Replace or rotate worn parts as needed -- hinge bolts,

clevis pins, bearings, etc.

8.

Grease wheel bearings and walking beams spar-

ingly. Over greasing may cause damage to seals and

reduce the life of the bearing. Grease hinge points

periodically.

9.

If machine is stored outdoors over the winter months,

it is a good idea to fold the machine then set it down

on the ground so all the cylinders are retracted to

protect the cylinder rods. This will extend the life of

the cylinder seals and reduce internal and external

leaks.

Storage

10. Store implement where children do not play. If possi-

ble, store the implement inside for longer life.

11. Remove any dirt and debris that can hold moisture

and cause corrosion.

12. Lubricate areas noted under “Lubrication”, page 22.

13. Inspect implement for worn or damaged parts. Make

repairs and service during the off season.

14. Use spray paint to cover scratches, chips and worn

areas on the implement to protect the metal.

By following and maintaining a routine service and lubri-

cation program, your tillage equipment will give you

many years of service.

For the most current manual information, visit Great

Plains website listed below. For more information on

operating, adjusting or maintaining your Great

Plains Discovator, assistance is available. Contact:

Product Support

Great Plains Mfg. Inc., Service Department

PO Box 5060

Salina, KS 67402-5060

(800)255-9215

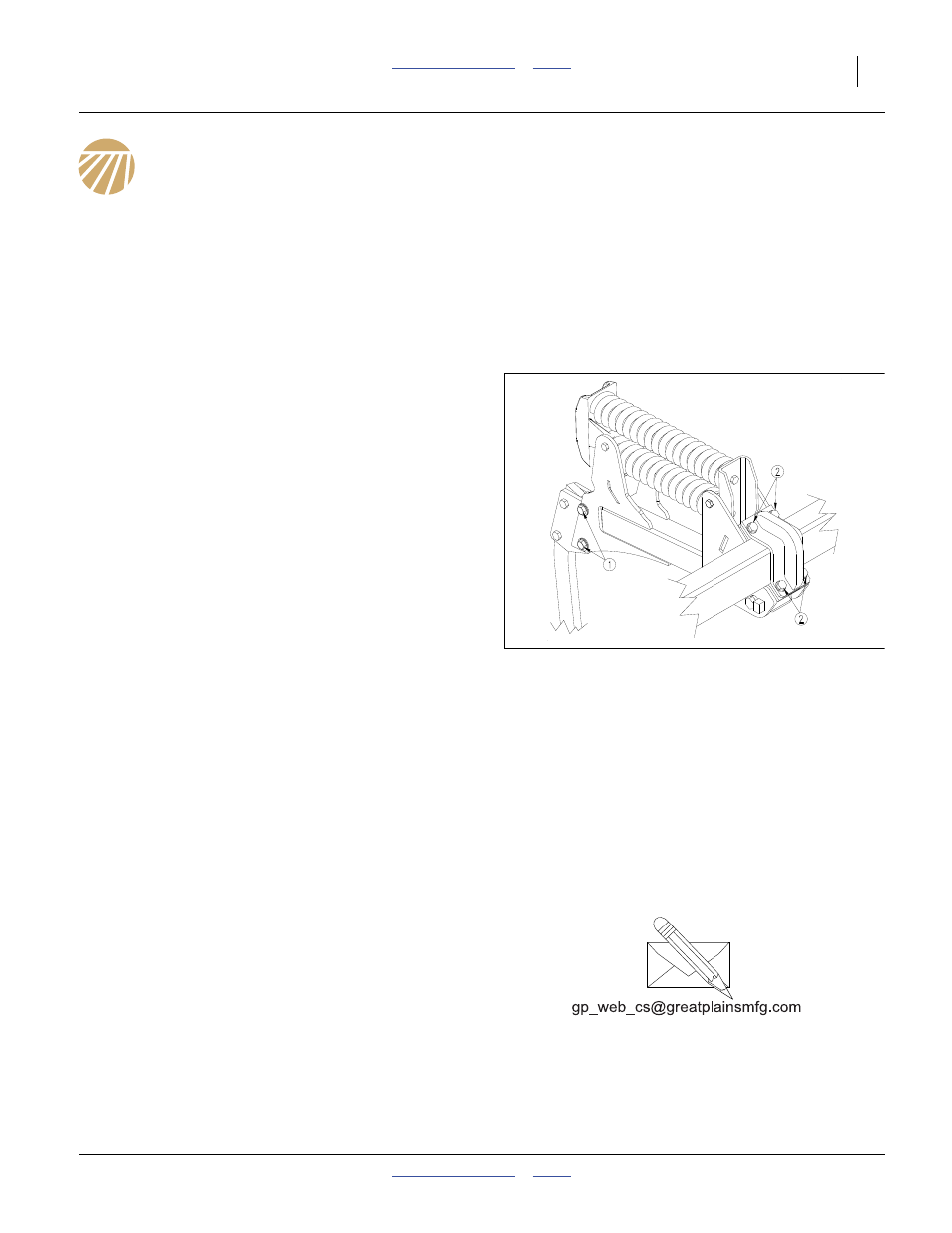

Figure 13

Auto Reset Shank Mount

22742