Gauge wheel adjustment, Coulter adjustment, Coulter height – Great Plains SS0300 Operator Manual User Manual

Page 20: Coulter alignment

16

SS0300

Great Plains Manufacturing, Inc.

596-224M

09/19/2011

Gauge Wheel Adjustment

Refer to Figure 8

1.

The jacks should only be used to help raise and lower

the gauge wheels. The cross pin still needs to be used

in order to avoid overloading the jack.

2.

Adjust the gauge wheel as shown on the decal on the

front of the frame

Coulter Adjustment

Coulter Height

1.

Determine the desired depth of the shank and set the

gauge wheel in the appropriate hole.

2.

Subtract 8” from the shank depth. Take this distance

and measure from the top of the frame to the top of the

coulter shank. This will allow the coulter to run approx-

imately hub deep. If trying to deep rip less than 8”,

position the top of the coulter shank flush with the top

of the tube.

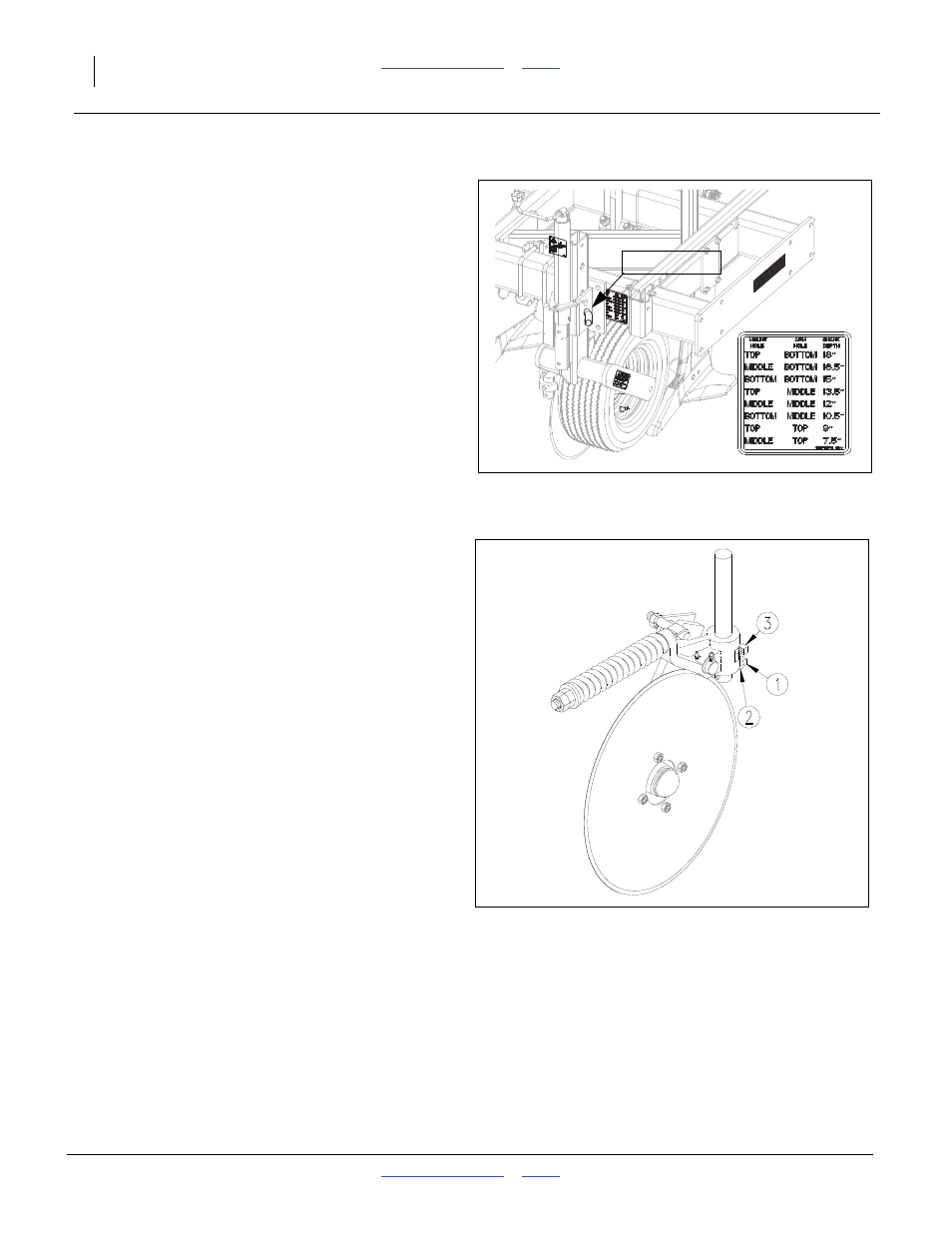

Coulter Alignment

Loosen the bottom set screw (1), jam nut (2) and

swivel limiter set screw (3). Lower the ripper in the

ground and drive forward a few feet.

2.

Leave the ripper in the ground and tighten the bottom

set screw (1) and jam nut (2). Position the swivel lim-

iter in the center of the slot and tighten the set screw

(3).

3.

Check alignment of the coulter and shank. Move either

the coulter or shank so the shank is in the center of the

grove made by the coulter.

Note: Note: If you want the coulter to swivel, loosen the bot-

tom set screw (1) and jam nut (2). Retighten jam nut

to prevent from loosing set screw.

Figure 8

Guage Wheels

41863

FigureSpacer:

FigureSpacer:

Cross Pin

Figure 9

Coulter Alignment

41863

FigureSpacer:

FigureSpacer: