2325-2335 purging hydraulic system, Completing setup, Reel shipping blocks – Great Plains 2335SC Predelivery Manual User Manual

Page 14

10

2112-2335SC

Great Plains Manufacturing, Inc.

540-072Q

10/08/2013

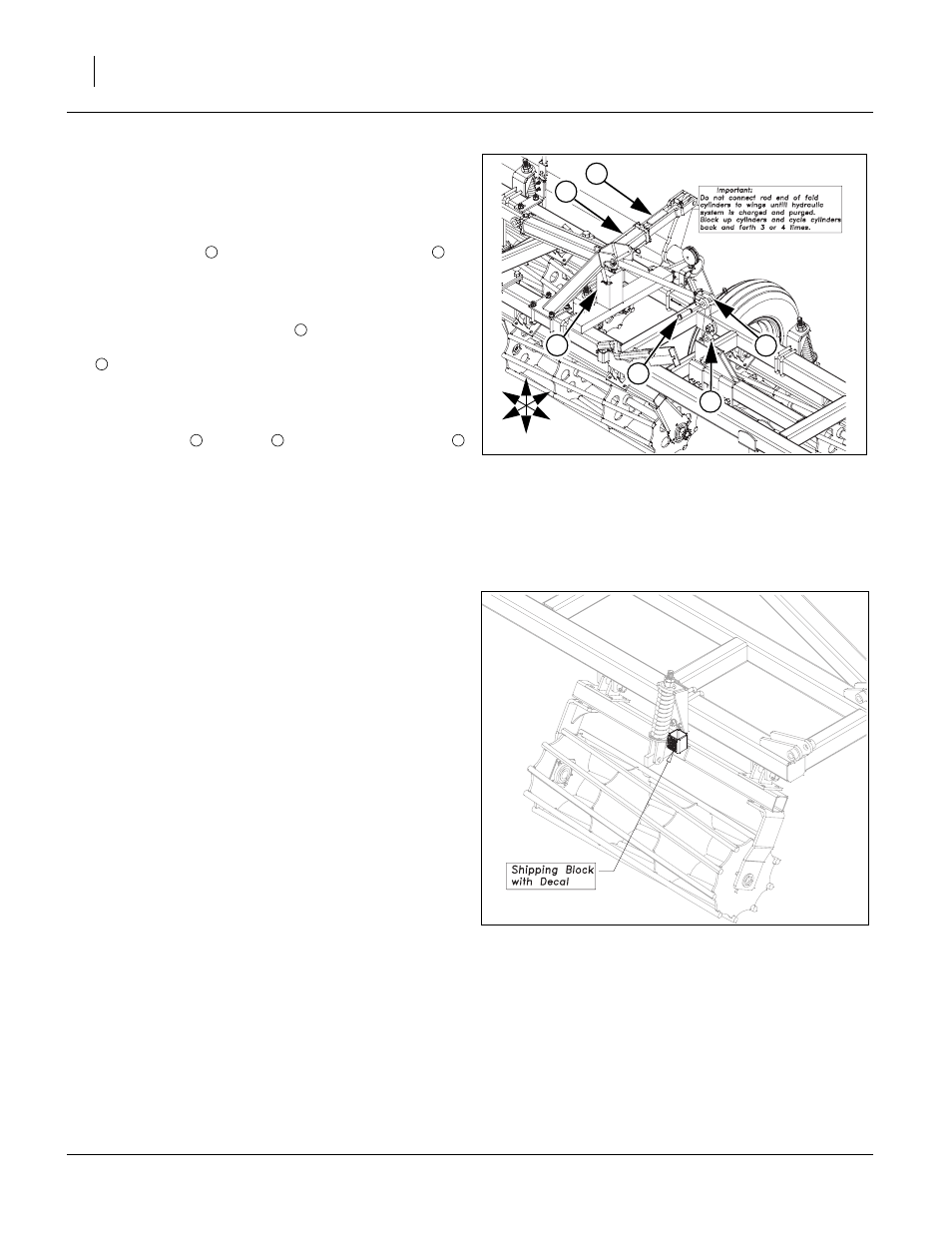

2325-2335 Purging Hydraulic System

Note: Make sure adequate oil is in the reservoir for the

pump as it will require several gallons of oil to charge

system. Do not connect rod end of fold cylinders be-

fore they are charged with oil. Be sure the rod end of

fold cylinders

are unpinned and wood blocks

are

supporting the fold cylinders so the cylinders won’t hit

anything while being purged.

Refer to Figure 9

22. Fully extend the lift cylinders

(yellow handles) until

the center section is fully raised. Flip the transport locks

up out of the way. Fully extend and retract the

hydraulic cylinders multiple times to purge all air from

the system and check for leaks.

23. After purging, you may connect the rod end of the wing

fold cylinders

to rocker

with the 1x3 11/16 pins

,

1.5x1.00x0.75 machine washer and 3/16x2 cotter pin.

24. Bend cotter pin to secure.

Note: If machine is equipped with the hydraulic down pres-

sure option, refer to the Hydraulic Down Pressure of

“Operator’s Manual” for the preparation and setup be-

fore going to the field.

Completing Setup

Reel Shipping Blocks

Refer to Figure 10

25. All seedbed conditioner baskets will be shipped with

shipping block with decal. Loosen spring and get pres-

sure off block, remove and discard blocks.

Figure 9

2325-2335 Hydraulic Purging

41408

6

3

4

1

5

2

U

D

F

B

L

R

1

2

3

4

1

5

6

Figure 10

Reel Shipping Block

41398