Danger, Spindles, hubs, wheels, & drive chain – Great Plains ADC1150 Operator Manual User Manual

Page 19

17

Section 1 Cart Assembly and Setup

7/28/10

Model 1150 1995 - 1997 167-058M

Great Plains Mfg., Inc.

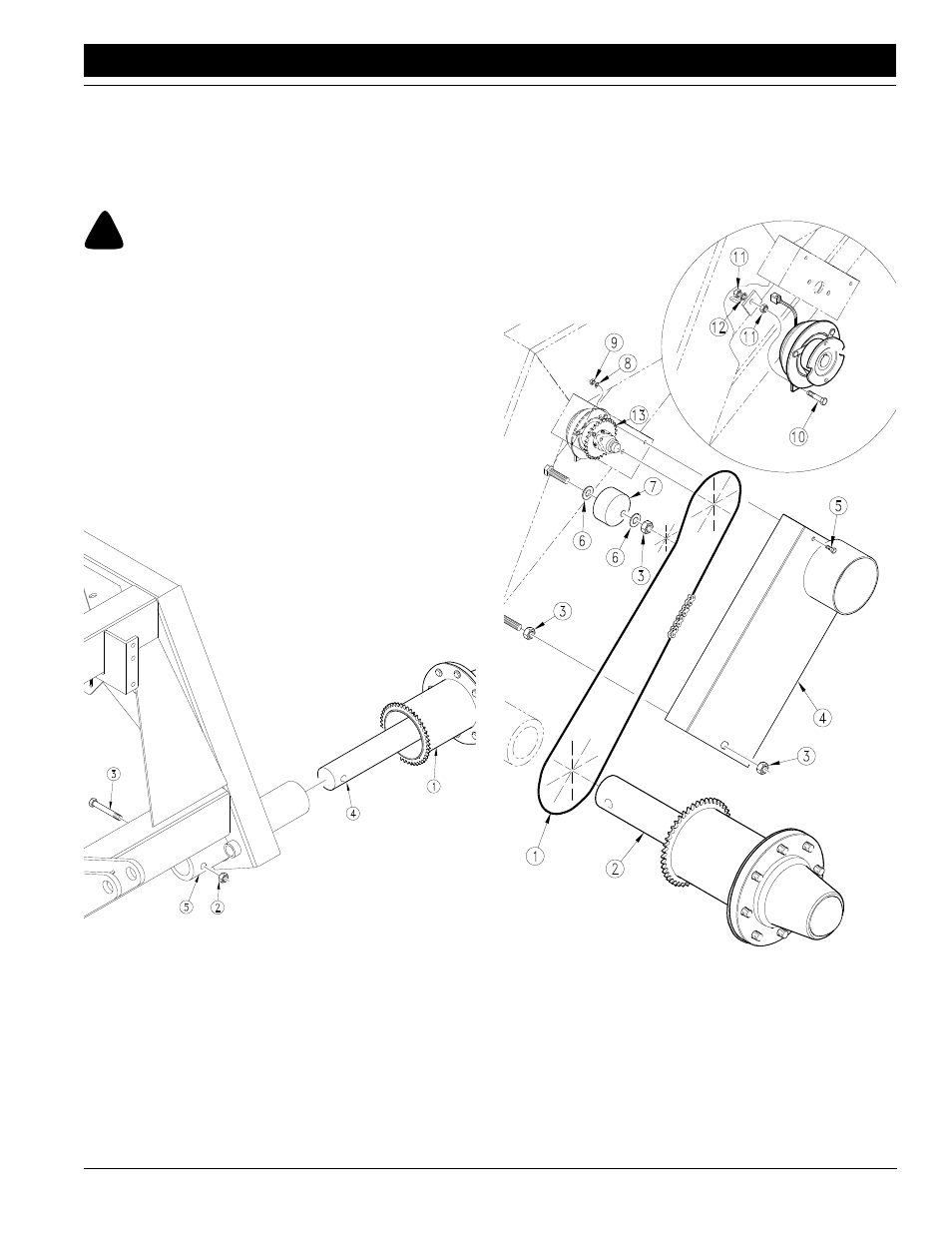

Spindles, Hubs, Wheels, & Drive Chain

Raise the rear of the cart off the ground high enough to let

the spindles slide into the tubes with hubs attached (the

spindle tube should be approximately 6” above the ground

at lowest point).

!

DANGER!

Crushing hazard. You may be severely injured or killed by the

drill if it falls. Always support the drill securely with jack stands

or blocks before working on unit raised off of the ground.

IMPORTANT: Put the hub and spindle assembly with the

drive sprocket on the right side of the drill. Install the as-

sembly without the drive sprocket on the left side of the

drill.

Refer to Figure 1-2 to and line up the bolt hole (#4) in the

hub and spindle assembly with the bolt hole in the spindle

tube (#5). Slide the hub and spindle assembly (#1) into the

tube until the holes are aligned, refer to Figure 1-2. Secure

the hub and spindle assembly in the tube using the 3/4” x

5” long bolt (#3) and the 3/4” lock nut (#2).

Refer to Figure 1-3:

Remove the drive chain mud guard (#5). Loosen the nut

(#7) securing the drive chain tensioner (#9). Turn tension-

er until the thinnest area is toward the front of the drill.

IMPORTANT: Before installing the drive chain make sure

that a 38 tooth sprocket is used on the clutch for the 34’

Spindle Installation

Figure 1-2

14459

implement and that a 29 tooth sprocket is used on the

clutch for the 45’ implement.

Install the main drive chain (#1) on the hub drive sprocket

(#2) and electric clutch sprocket (#16). The chain goes in

front of the drive chain tensioner (#9).

Rotate the drive chain tensioner counterclockwise to re-

move excess chain slack then re-tighten nut (#7) to se-

cure. Check alignment of the chain and sprockets. If

adjustment is needed, loosen the set collars (#1) holding

14436

Main Drive Chain Installation

Figure 1-3