Great Plains 3S-4000F Predelivery Manual User Manual

Page 26

3S-4000

195-242Q

9/12/2009

24

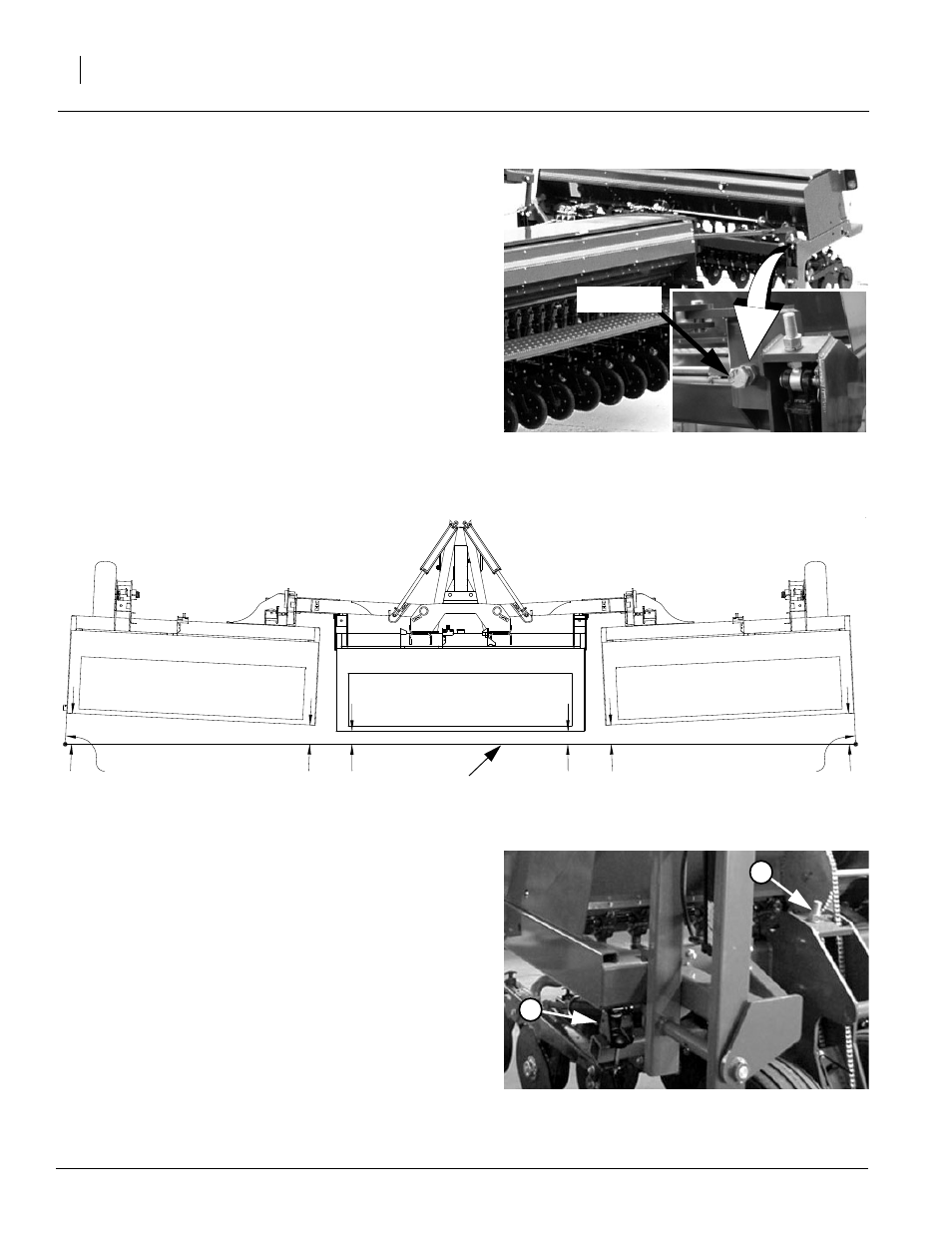

Wing Box Alignment

1.

Place a block ahead of the wing gauge

wheels.

2.

Pull forward against blocks to rock wing

frames back. Pull forward until stop bolts are

firmly against toolbars. Refer to Figure 8 for

stop bolt location.

3.

Check for proper alignment by running a

string line across back of drill toward outer

ends of wings. For proper alignment, outside

ends of boxes should be about 1 inch to 1-1/4

inch ahead of inside ends. See Figure 9.

4.

To adjust box alignment, shorten or lengthen

stop bolts to change the contact point with the

toolbars. Adjust stop bolts in or out until out-

side ends of boxes are 1 inch to 1-1/4 inch

ahead of inside ends.

Opener Frame Clearance

Refer to Figure 10.

When fully raised, top of opener mounts (1)

should clear bottom of drill frame tube by at least

1/2 inch.

To adjust opener frames so all openers have the

same clearance, loosen jam nut (2) on opener lift

cylinders and turn adjustment nut. When openers

are at the correct height, retighten jam nut. Re-

peat at each opener lift cylinder if necessary.

Figure 8

Stop Bolt Location

Stop Bolt

String Line

String Line

Support

String Line

Support

A

A

B

C

B

C-B=1 to 1-1/4 inch

C

Figure 9

Wing Box Alignment Measurement

15654

18853

Figure 10

Opener Frame Clearance

1

2