Ace pumps, Ace hydraulic pump seal replacement, Ace pump disassembly – Great Plains 3P300 Operator Manual User Manual

Page 51

Great Plains Manufacturing, Inc.

Maintenance and Lubrication

47

09/14/2009

500-103M-A

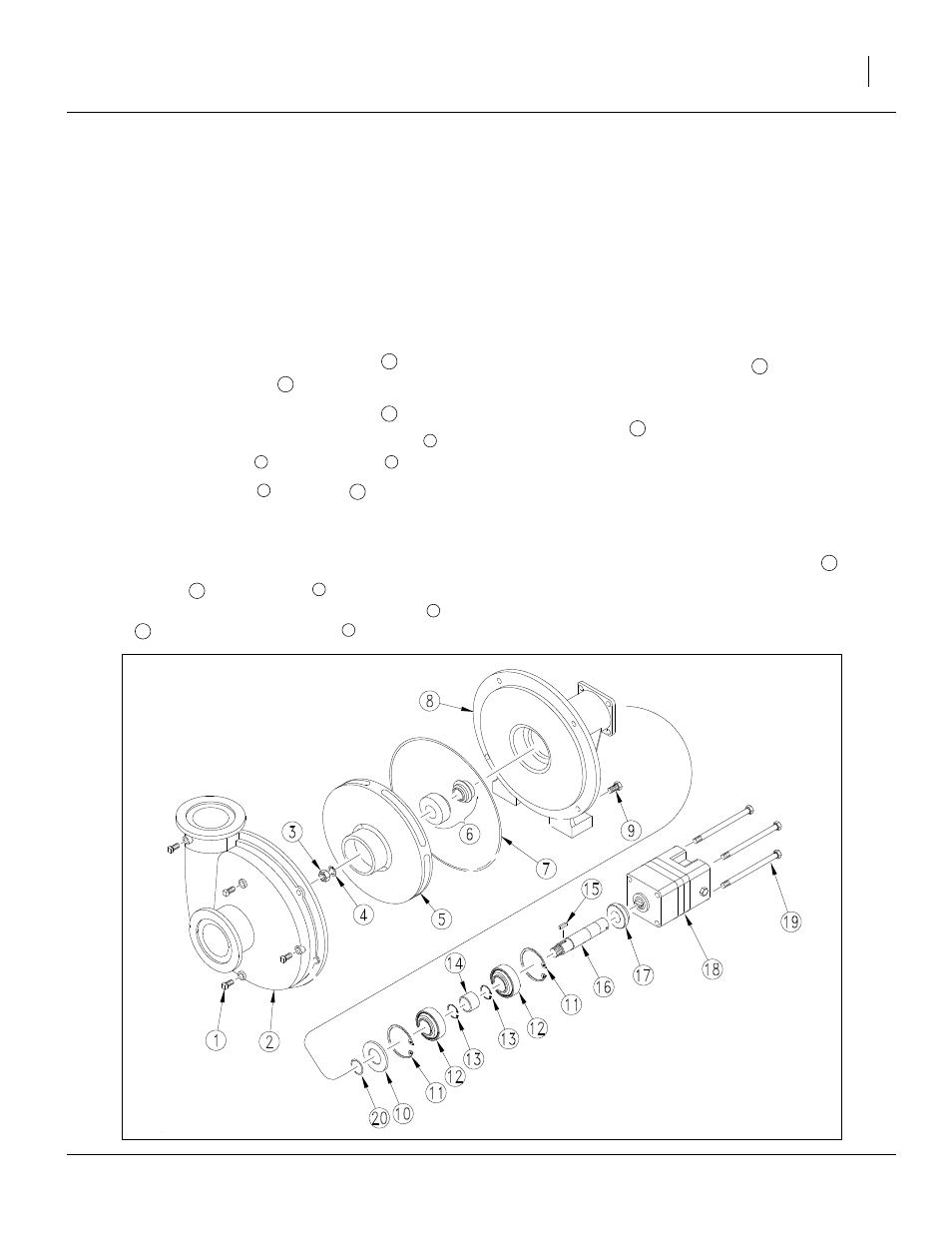

Ace Pumps

The Ace pump is designed for long life and service. After

some years, a mechanical seal may weep slightly, but if it

starts to drip, the pump will have to be disassembled.

Before disassembly, be sure to wash it out with fresh

water.

If the pump leaks, before removal from sprayer, run the

pump with adequate water in tank to diagnose the actual

pump problem.

Ace Hydraulic Pump Seal Replacement

Ace Pump Disassembly

1.

Remove four

5

⁄

16

in hex head cap screws

from rear

of motor. Remove motor

and coupler.

2.

Remove rear internal bearing snap ring

.

3.

Remove four

3

⁄

8

in x

3

⁄

4

in hex head cap screws

from mounting frame

. Remove volute

.

4.

Remove

3

⁄

8

in lock nut

from shaft

. Insert a flat

file into impeller vane to hold stationary.

CAUTION: Excess torque may cause damage to

plastic impellers.

5.

Press shaft

out of impeller

using one

5

⁄

16

in hex

head cap screw from step 1. Remove impeller

,

key

, and rotating seal member

.

6.

Press shaft/bearing assembly out of frame.

7.

Remove stationary seal member

by prying out

with screwdriver or pressing out from motor end of

pump housing.

8.

Remove o-ring

from shaft groove.

Note: If replacing only the pump seal:

a) Press the shaft /bearing assembly into frame.

b) Reinstall rear internal bearing snap ring.

c) Skip to Assembly step 8.

9.

Press bearings off of shaft.

10. Remove forward internal bearing snap ring

.

Figure 29

Ace Hydraulic Pump

23373

19

18

11

9

8

2

3

16

16

5

5

15

6

17

20

11