Sprayer calibration, Manual pressure valve, Sprayer calibration manual pressure valve – Great Plains 3P300 Operator Manual User Manual

Page 25

Great Plains Manufacturing, Inc.

Preparation and Setup

21

09/14/2009

500-103M-A

Sprayer Calibration

Sprayer calibration prepares your sprayer for operation

and diagnoses nozzle wear. This gives you optimum per-

formance from your nozzles and ensures accurate appli-

cation.

Equipment that may be needed:

• 817-199C Calibration Container

• Great Plains Nozzle Tip Calculator:

832-038C - U.S. customary units (English), or

832-058C - Metric (English/Russian legends)

• General calculator

• Stopwatch or wristwatch with second hand.

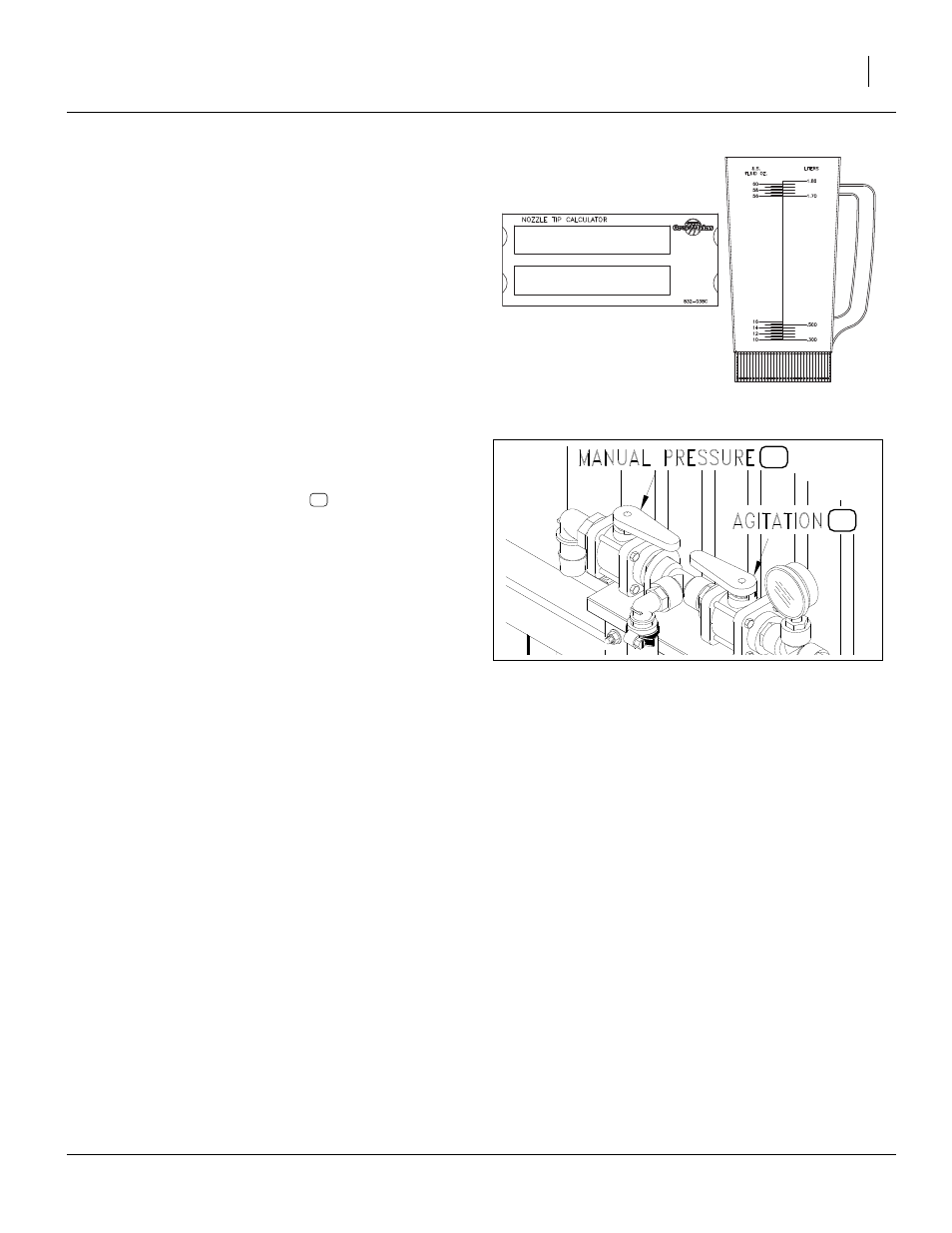

Manual Pressure Valve

Refer to Figure 10

When the manual pressure valve

is full open, the

pressure adjustment can be very sensitive.

• If sprayer is equipped with an automatic controller, the

butterfly valve will have to move more often causing

additional wear.

• If your 2007- sprayer is equipped with manual controls

plumbing, the pressure adjustment switch on the con-

trol box will be more sensitive and it will be hard to set

the pressure.

To decrease the sensitivity, set the manual pressure

adjustment valve as follows:

1.

Open the control valve so that it is wide open and

there is full flow to the sprayer booms. On a sprayer

with manual controls, adjust the pressure switch. On

an automatic controller, open the butterfly valve until

it is full open.

2.

Shut the manual pressure adjustment valve down so

the pressure is about 20 PSI greater than the pres-

sure you will spray at. The pressure the spray will be

applied at is determined when calibrating sprayer.

Refer to the Application Guide.

With this valve set, it will decrease the flow through the

electric ball valve and reduce the sensitivity of the pres-

sure adjustment switch.

27165

Figure 10

Agitation/Manual Pres. Valves

15783

1

2

2