Pump maintenance & repair, Great plains pto pump – Great Plains 3P300 Operator Manual User Manual

Page 50

46

3P300 S/N HH1113+

Great Plains Manufacturing, Inc.

500-103M-A

09/14/2009

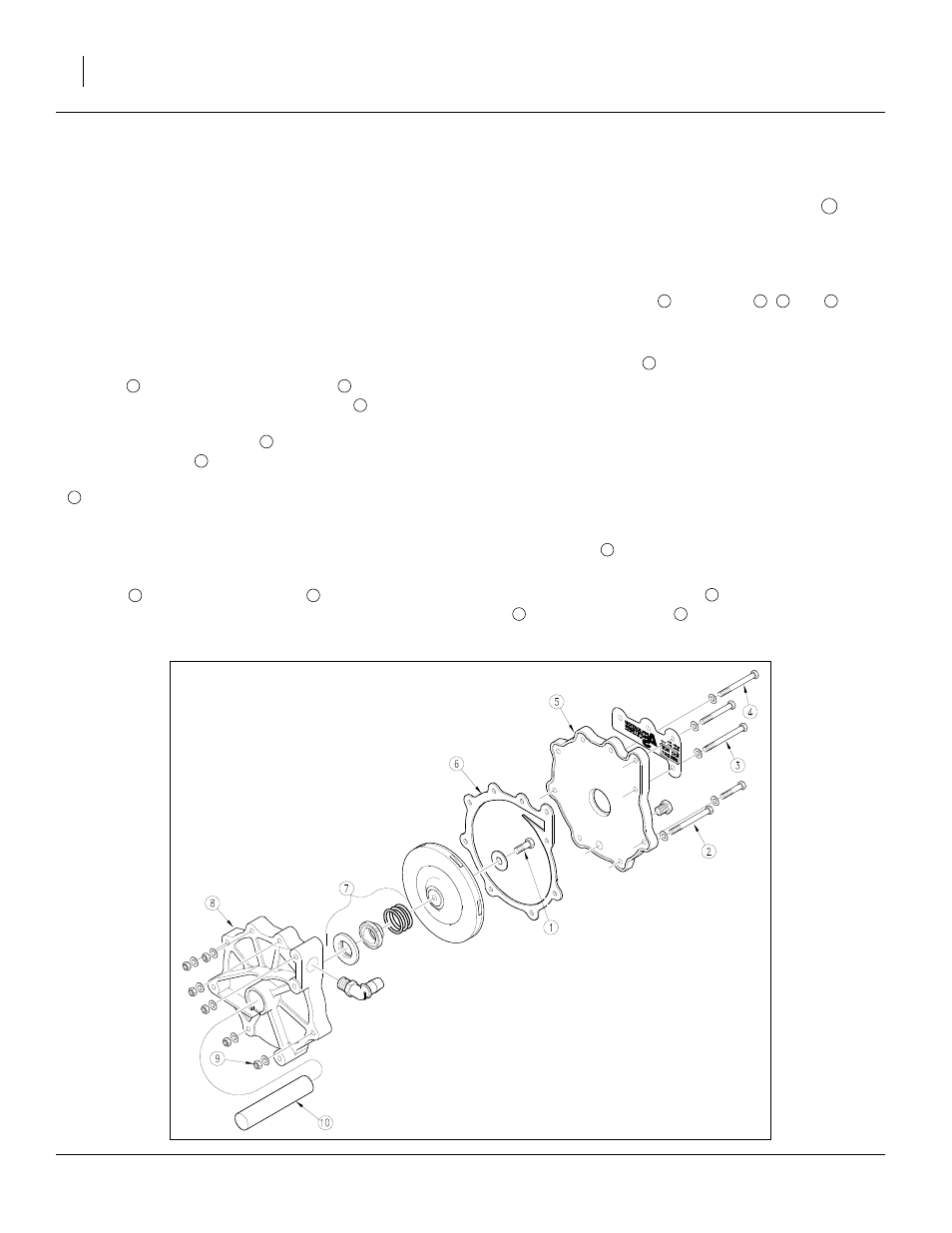

Pump Maintenance & Repair

Great Plains PTO Pump

The Great Plains pump is designed for long life and ser-

vice. After some years, a mechanical seal may weep

slightly, but if it starts to drip, the pump needs disassem-

bly. Before disassembling the pump be sure to flush it

with fresh water. The Parts manual has current compo-

nents part numbers.

Refer to Figure 28

Before removing a leaking pump, run the pump with ade-

quate water in the tank to diagnose the actual pump

problem. If fluid leaks out between the front suction

housing

and the rear volute housing

, the housing

gasket may be dried out. Give the gasket

adequate

time to absorb moisture and swell up. If necessary,

retighten the volute housing

by alternating on opposite

sides until all nuts

are torqued to 16 - 18 ft.-lbs. It is a

good practice to apply grease to both sides of the gasket

to prevent shrinkage.

If seal replacement is required:

1.

Disassemble pump and clean all components.

2.

Assemble the ceramic ring seat of the mechanical

seal

into the volute housing

of the pump. Make

sure the ceramic seat is positioned square into the

volute housing.

3.

Clean off any grease or dirt from pump shaft

and

dry the shaft so the rubber bellows on the mechani-

cal seal will adhere to the shaft properly when

assembled.

4.

Bolt up the pump input bearing housing (not shown)

to the volute housing

using bolts

,

and

with

spacers (not furnished) for alignment and assembly

of the shaft seal.

5.

Assemble the seal

without its spring, on the pump

shaft by pushing on the inside rubber portion of the

seal using water as the lubrication. The graphite seal

face should touch the white ceramic seat face. The

rubber bellows adhering to the pump shaft should

not protrude more than

1

⁄

16

in (1.6mm) beyond the

stainless steel ring on the impeller side of the seal.

6.

Assemble the seal’s spring and the impeller, being

careful not to move the mechanical seal that has

been positioned on the pump shaft. Torque the

impeller bolt

16-18 ft-lbs (22-24 N-m).

7.

Remove the three bolts and spacers. Using gun

grease, lubricate the gasket

. Assemble the gasket

and suction housing

using bolts, flat washers

and locknuts. Torque nuts 16 - 18 ft./lbs.

Figure 28

GP Centrifugal Pump Assembly

11591

5

8

6

8

9

6

7

8

10

8

2

3

4

7

1

6

6

5