Great Plains PFH-20 Operator Manual User Manual

Page 20

18

Section 3 Troubleshooting

PH-15, PH-20, PFH-15 and PFH-20 Coulter Command System 148-384M

6/21/2004

Great Plains Mfg., Inc.

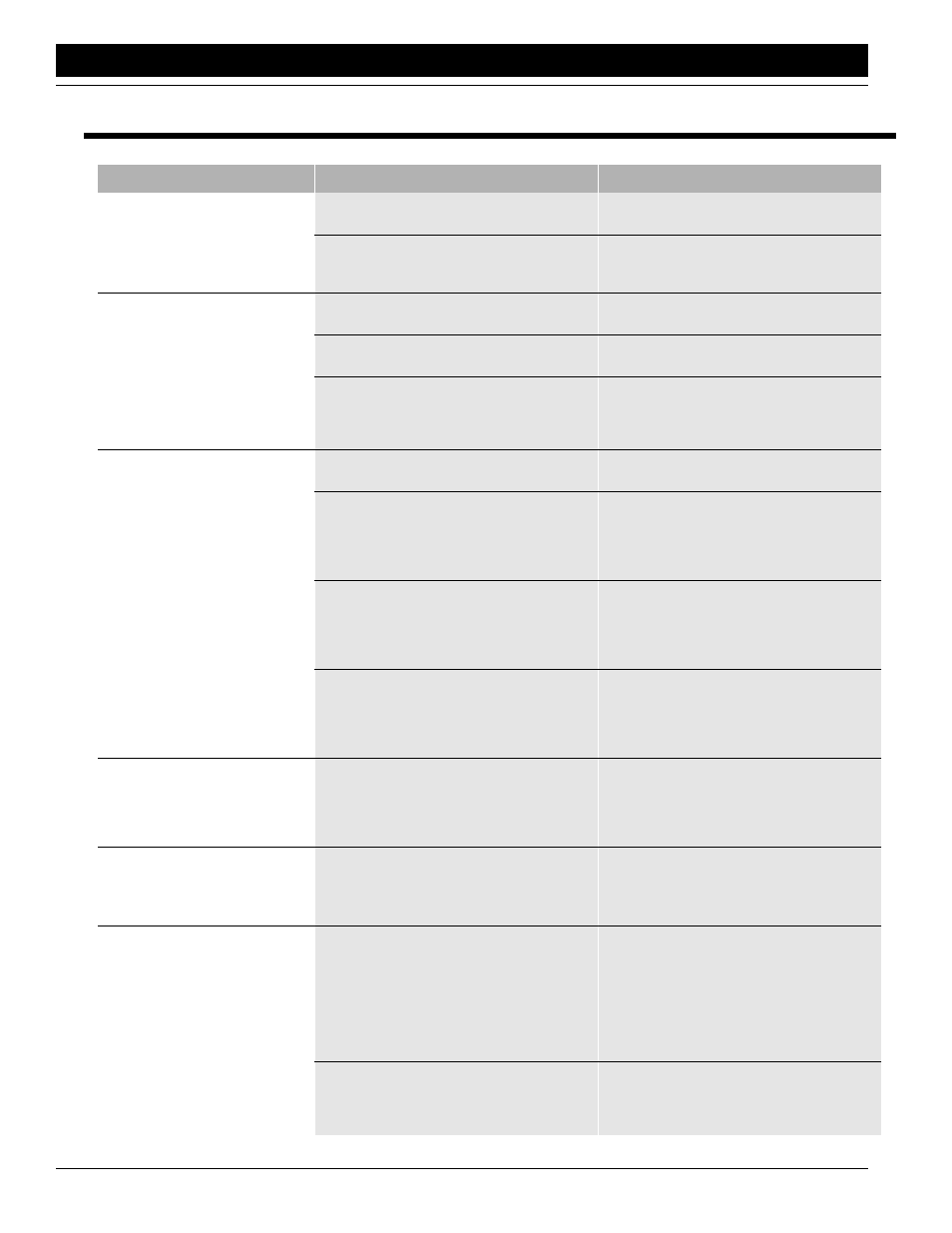

Problem

Possible Cause

Solution

Coulters move up when the

down switch is operated and

down when the up switch is

operated.

Not supplying oil to the "P" port of the

hydraulic valve.

Reverse the remote hydraulic lever in the

tractor.

Solenoids wired backward or hoses from

port "A" and port "B" reversed at the

hydraulic valve.

Unplug solenoids and swap wire leads to

them.

Automatic Coulter depth con-

trol stops adjusting coulter

depth

TONGUE HYDRAULICS switch bumped to

MANUAL mode.

Flip TONGUE HYDRAULICS switch back to

AUTO mode

Tractor remote hydraulic lever not locked for

constant oil supply to valve.

Lock Tractor remote hydraulic lever with

rubber tarp strap or other means.

System variables out of adjustment

Turn power switch OFF and back on again

so system variables can reset. Then flip the

AUTO-MANUAL switch to AUTO and

resume operation.

Turning the COULTER DEPTH

knob does not set coulters

deep enough.

If the tongue cylinder runs completely

retracted, the tractor drawbar is to high.

Use a straight drawbar or one which

sweeps down.

If in extremely hard conditions with the

machine standing the tongue cylinder

pulses but does not retract.

This is perfectly normal. The cylinder will

not penetrate the coulters on a stationary

machine in hard conditions. Pull forward

and check coulter depth on a moving

machine.

If the COULTER DEPTH knob is turned to

"A" and the tongue cylinder will not com-

pletely retract when moving through the

field then the internal sensor box linkage is

not set correctly.

Adjust the sensor box internal linkage. See

"Sensor Box Adjustments" on page 13.

If the sensor box linkage is properly

adjusted and tongue cylinder constantly

pulses while moving through the field but

the front tongue cylinder will not retract, you

do not have enough system weight.

Add fertilizer or water to liquid tanks. Add

tool bar weight brackets to coulter tool bars.

The hydraulic valve con-

stantly pulses when you are

stopped to refill or adjust

something.

Hard soil conditions are hindering coulter

penetration while stopped.

Flip TONGUE HYDRAULICS switch to

MANUAL mode while you are stopped or

turn coulter command power OFF. Pulsing

does not hurt the valve, but

can be annoy-

ing.

Turning the COULTER DEPTH

switch to "E" does not allow

the coulters to run shallow

enough.

The internal sensor box linkage is not set

correctly.

Adjust the sensor box internal linkage. See

"Sensor Box Adjustments" on page 13.

Depth sensing gauge wheel

not lifting off the ground when

Precision Hitch is raised.

Coulter Command power is OFF or 12 volt

power has been interrupted.

Coulter Command must be connected and

the power must be ON for the depth sens-

ing gauge wheel to raise when the Preci-

sion Hitch is raised. The depth sensing

gauge wheel should raise with the transport

lift circuit with Coulter Command in either

the AUTO or MANUAL mode is long as the

power is ON.

The lift switch has become disconnected or

the lift switch cam on the rockshaft is not

properly adjusted.

Adjust the lift switch cam. See "Lift Switch"

under Section 2 "Operating Instructions"

on Page 16.Check cable connections on lift

switch leads.

Section 3

Troubleshooting