Load sensing hydraulics, Hydraulic hook-up & function – Great Plains PFH-20 Operator Manual User Manual

Page 16

14

Section 2 Operating Instructions

PH-15, PH-20, PFH-15 and PFH-20 Coulter Command System 148-384M

6/21/2004

Great Plains Mfg., Inc.

The Coulter Command couples a microprocessor with

electro-hydraulics to provide a state-of-the-art system for

maintaining coulter depth regardless of the terrain or soil

type. It also provides coulter depth adjustment from the

tractor cab. A manual feature allows manual control of the

front hydraulic tongue cylinder for hitching, unhitching, or

making adjustments. To understand the Coulter Com-

mand system, one must be familiar with the functions of

the Hydraulics and the Electronic controls.

Load Sensing Hydraulics

To operate Coulter Command, some tractors with load-

sensing or constant-flow hydraulics require a bypass

valve, Great Plains part number 810-400C. Contact your

Great Plains dealer to order the bypass valve.

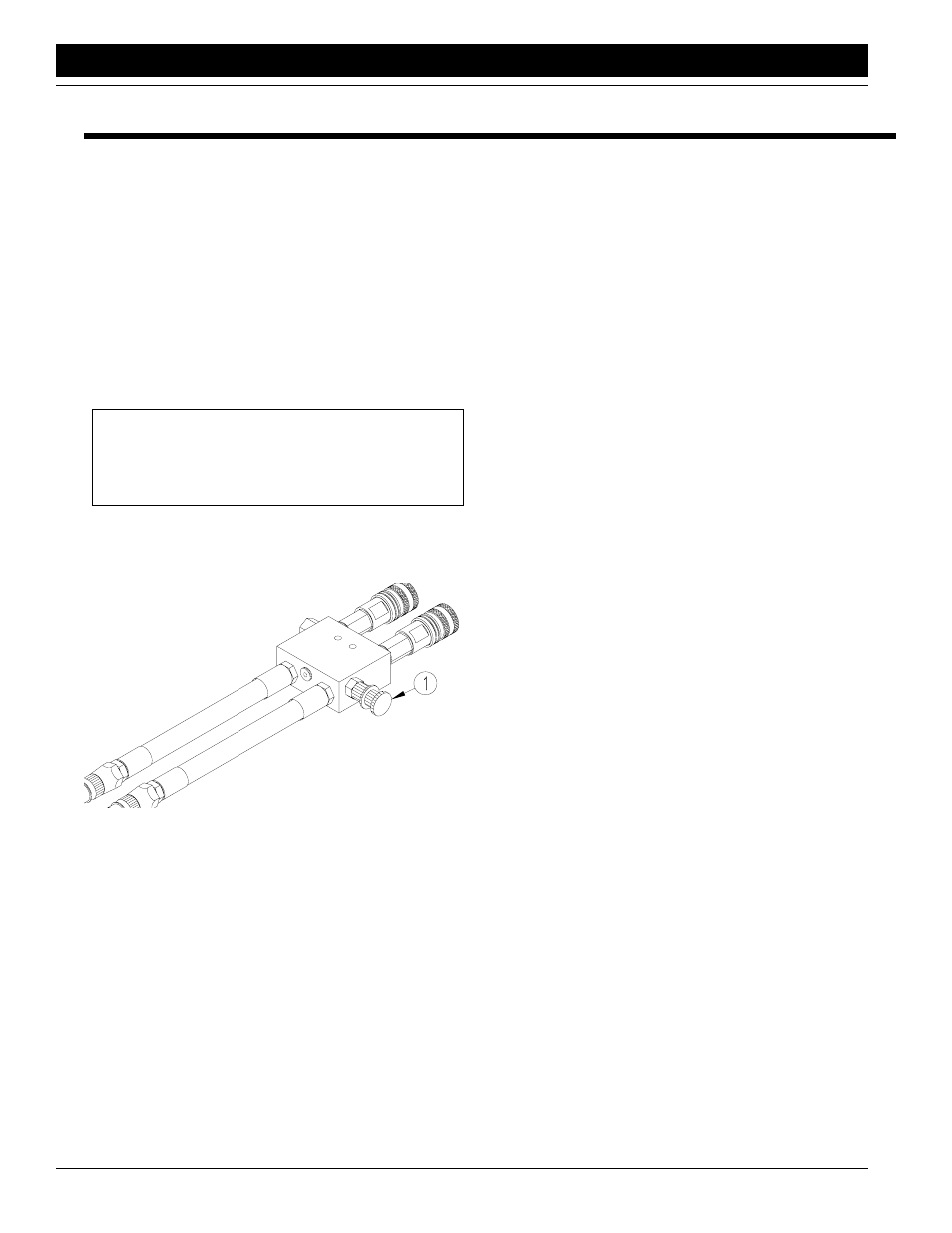

After installing the bypass valve, set valve as follows:

1.

Close bypass valve for no oil flow by turning knob (1)

on valve clockwise. See Figure 2-1.

Figure 2-1

Bypass Valve

2.

Adjust flow-control valve for tractor to a maximum of

10 gpm. If you do not have a flowmeter, hook a stan-

dard 8-inch stroke, 4-inch bore cylinder to the circuit.

At 10 gpm, the cylinder will take about 2.6 seconds to

extend.

3.

Engage tractor hydraulics for Coulter Command.

4.

Using a pressure gauge, turn knob on bypass valve

counterclockwise until pressure gauges reads 1800

psi. Lock bypass valve at this setting.

NOTE: Failure to install a bypass valve on load-sens-

ing tractors may cause major tractor damage. Consult

your tractor dealer to verify if the bypass valve is need-

ed.

17987

Hydraulic Hook-Up & Function

Tractors with closed-center hydraulic systems and

variable displacement hydraulic pumps.

(If you are not familiar with your tractor's hydraulics, con-

sult your tractor dealer.)

For tractors with closed-center hydraulics or pressure/flow

compensated hydraulics which are powered by a variable

displacement hydraulic pump, turn the knurled control

knob on the left side of the hydraulic valve completely

clockwise and lock it in place with the circular lock disk. Do

not apply any torque to the control knob after it bottoms out

or valve damage may occur. Be sure the lock disk is

snugged to prevent the control knob from vibrating loose in

field operation.

The tongue cylinder hydraulic circuit consists of the hoses

from ports "P" and "T". Once the hydraulic valve is set for

CLOSED CENTER operation, the Coulter Command

tongue cylinder circuit requires live hydraulic power sup-

plied to the port labeled "P". This is accomplished by

pushing FORWARD on the tractor remote hydraulic lever

and LOCKING IT OPEN in this position.

•

On John Deere tractors equipped with SOUND-GUARD

R Body you must use the LEVER LOCK CLIP John

Deere Part No. R52667 to lock the lever in the forward

position. See your tractor dealer for purchase and instal-

lation of this clip.

•

On John Deere 7000 Series tractors, rotate valve detent

selector to MOTOR POSITION to lock the lever in the

forward position.

•

On Case-IH Magnum tractors use the circuit designed

for HYDRAULIC MOTOR CONTROL and lock the lever

forward in the detent position. The detent pressure will

probably have to be turned up to its maximum setting.

DO NOT tie the hydraulic lever on past the detent posi-

tion with a strap. This could shift the spool beyond its de-

signed operating position and cause system damage.

See your tractor dealer for hydraulic system details.

•

On other model tractors use the circuit designed for HY-

DRAULIC MOTOR CONTROL and lock the lever for-

ward in the detent position. The detent pressure will

probably have to be turned up to its maximum setting or

some other mechanical detent holder will have to be

used to hold the lever forward. See your tractor dealer

for the proper means of providing constant pressure/

flow to the tongue cylinder circuit.

The Coulter Command hydraulic circuit requires a flow

rate of 8 to 12 gallons per minute for efficient operation. On

high flow rate tractors, the flow control on the tractor re-

mote may have to be turned down so as not to exceed 12

gallons per minute. Flow rates higher than 12 gallons per

minute will not damage the valve, but may cause poor

Coulter Command performance.

The remote tractor hydraulic lever will have to be locked in

Section 2

Operating Instructions