Great Plains 30-Foot 3-Section Vintage Drill User Manual

Page 10

4/8/04

1-8

113-368M

11757

MAINTENANCE AND LUBRICATION

1.

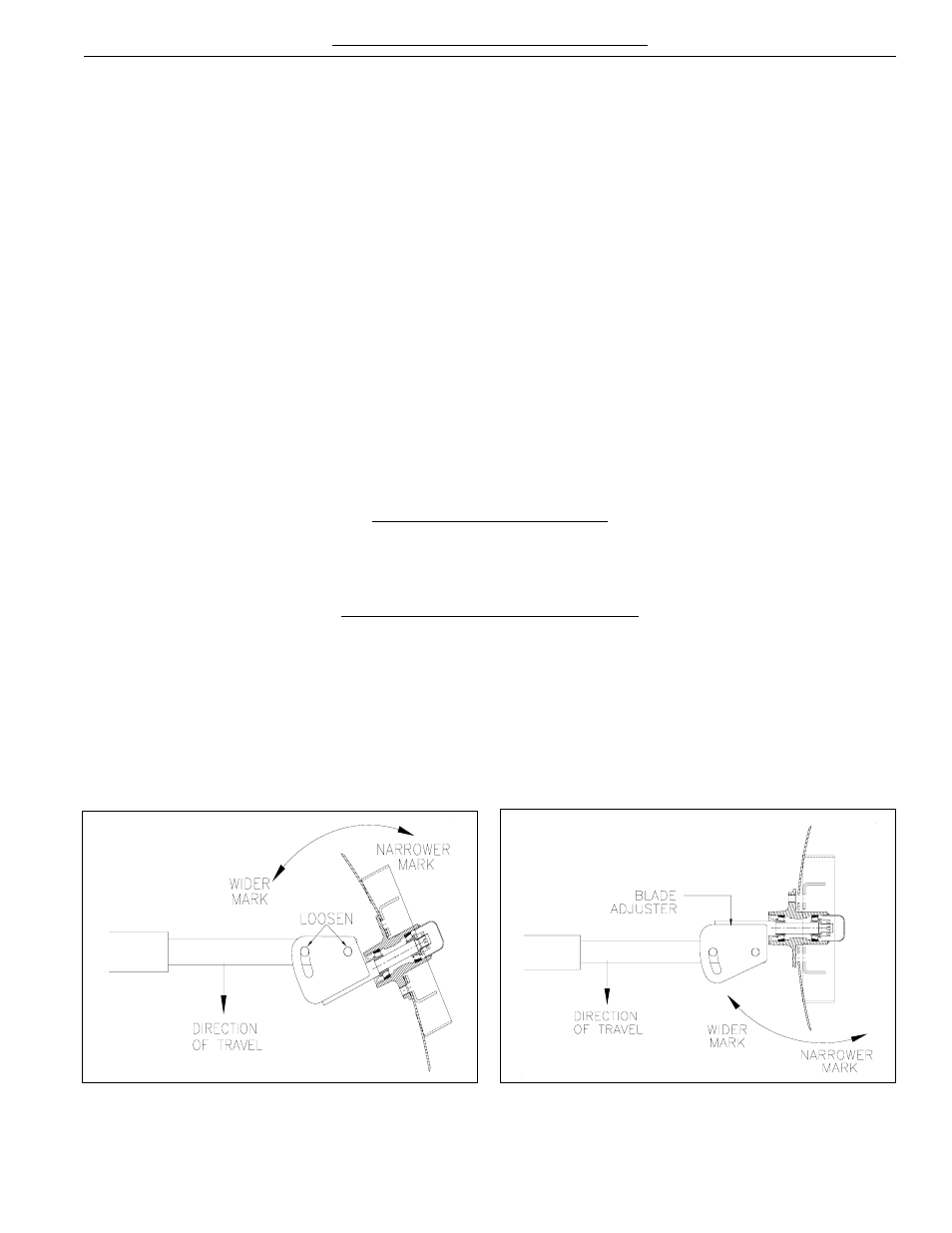

The marker blade comes factory assem-

bled as shown in Fig. 3. The width of the mark

that the blade makes can be adjusted by chang-

ing the angle of the blade. This is done by loos-

ening the two 1/2" bolts in the blade adjuster,

pivoting the blade to the preferred angle and

tightening the bolts.

2.

If desired, the angle of the blade can be re-

versed by turning the blade adjuster upside

down and reversing the blade so the depth band

is on the inside as shown in Fig. 4.

Fig. 3

Fig. 4

MARKER BLADE ADJUSTMENTS

BREAKAWAY PROTECTION

The marker arm (#2) is attached to the marker body (#1) with a 3/8" shear bolt. If excessive force is

put on the marker during operation, the shear bolt will break, allowing the marker arm to swing away

rather than cause damage to the marker.

NOTE: The breakaway bolt is a 3/8"-16 x 2" long - grade 2 (G.P. # 802-266C). It is identified as a

grade 2 by having no marks on the head. If it breaks, it must be replaced by an equivalent grade 2

bolt to prevent marker damage.

LUBRICATION

HINGES

The marker body hinge pivots require greasing every 20-25 hours of operation. Each marker has

two grease fittings located at the center of each end of the first section.

DISK BEARINGS

The tapered roller bearings in the disk hub are lubricated at the factory. Under normal conditions,

the bearings need to be repacked every 2 to 3 years. If the grease seal or grease cap becomes dam-

aged or is missing, the hub should be disassembled, cleaned and bearings repacked. A new seal or

grease cap should be installed.

MARKER TRANSPORTING

Always transport the marker with it folded in the flat fold position. Make sure the second marker

section(s) rests securely on the transport carrier(s).

11248