Carrier MINIMUM LOAD CONTROL ACCESSORY 30RB060-390 User Manual

Page 3

3

.

6. Dehydrate and recharge each circuit.

7. Restore power to the unit.

NOTE: When piping is completed, leak test the assembly.

Then evacuate, dehydrate, and recharge the circuit using

approved refrigeration practices. Be sure to use the correct

type and amount of refrigerant listed in the nameplate data

and base unit documentation.

Install Control Wiring (See Fig. 6 and 7)

1. One control wire harness is supplied per circuit.

Secure the DIN connector end on the solenoid valve

coil with the screw in the connector. Verify the square

rubber gasket is in place to ensure connection remains

watertight.

2. Route the other end of the cable to the main control panel

(where the display is located). For the circuit A solenoid,

connect leads to TB5-7 and TB5-13. For the B circuit

solenoid, connect leads to TB5-8 and TB5-13. For the

C circuit solenoid (30RB210-300 only), connect the leads

to TB5-6 and TB5-13. In all cases the black wire from the

solenoid must be connected to TB5-13 to ensure correct

polarity. Incorrect polarity will damage the control

boards.

3. For 30RB250-300 units only, locate fan board 3 (FB3) in

the C circuit power control panel. Route the C circuit

solenoid cable to the panel. Locate the orange and brown

wires from channel 7 of connector J3 on this board.

Connect the red wire from the solenoid to the orange wire

from the board. Connect the black wire from the solenoid

to the brown wire from the board.

Configure Unit for Minimum Load Control —

The control must be configured for the minimum load control

operation. Use the scrolling marquee display to configure the

system.

1. Set the Enable/Off/Remote switch to OFF position.

2. Press

until the screen is blank and use the

arrow key to select the Configuration mode LED (light

emitting diode).

3. Press

, then use arrow key to select the

sub-mode ‘UNIT’, then press Enter key.

4. Press the down arrow key until ‘HGBP’ is displayed.

5. Press

key twice. The word ‘PASS’ and

‘WORD’ will flash.

6. Press 0 1 1 1 then

key so that ‘0’ flashes.

7. Use arrow keys to change value to one of the following

configurations:

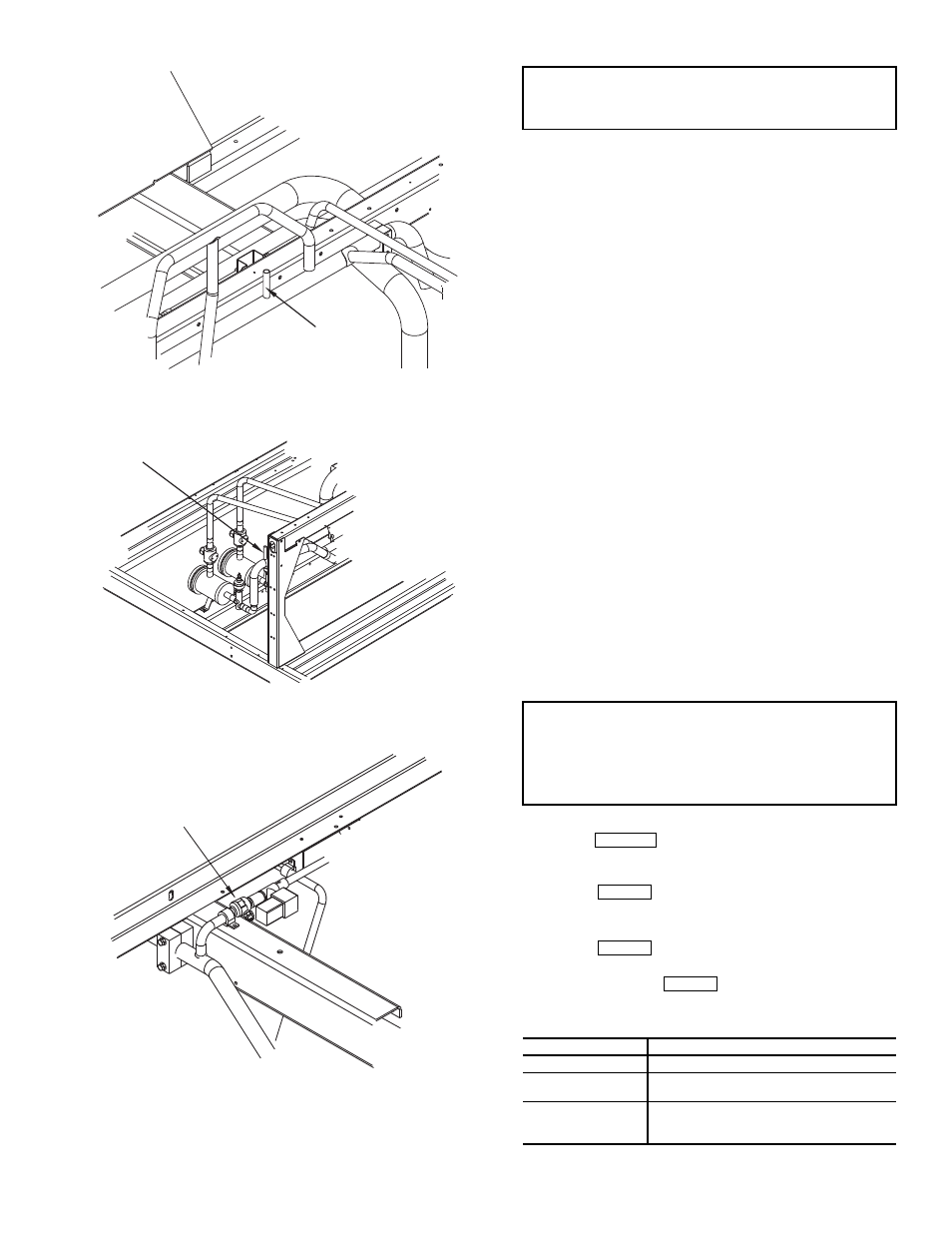

DISCHARGE STUB

Fig. 2 — Typical Stub Tube View

COOLER STUB

Fig. 3 — Stub Tube for Circuit A of Size 110

BALL VALVE

Fig. 4 — Typical View of

5

/

8

in. Swage Tube,

5

/

8

in. Clamp and Solenoid Valve Installed

IMPORTANT: The valve is direction specific and must

have the arrow pointing toward the cooler. The solenoid

valve will not properly seat if installed backwards.

IMPORTANT: This accessory can only be used on units

configured for Cooler Fluid Type (Configuration

SERV

FLUD = 1 [Water]). The minimum load control

accessory (HGBP) is not allowed on units configured for

Cooler Fluid Type (Configuration

SERV

FLUD = 2

[Brine]).

CONFIGURATION

DESCRIPTION

1

Used during chiller start-up only

2

Used during start-up and for close

control of leaving fluid temperature

3

Used during start-up, for close control

of the leaving fluid temperature and for

high ambient unloading

ESCAPE

ENTER

ENTER

ENTER