Mesur-fil fluid couplings, Selection and sizing, Fill levels (nema b motors) – Wichita Clutch Fluid Coupling User Manual

Page 7

Mesur-Fil Fluid Couplings

160

Wichita Clutch 800-964-3262

P-1100-WC 1/12

1200 RPM 1800 RPM

HP Cplg. Fill % Cplg. Fill % HP KW

Size No. Slip Size No. Slip

1/2 7.0 12 6 7.0 8 3 1/2 0.38

3/4 9.4 8 3 7.0 8 4 3/4 0.56

1 9.4 8 3 7.0 9 4 1 0.75

1 1/2 9.4 8-1/2 3 7.0 11 5 1-1/2 1.1

2 9.4 9 4 7.0• 12 6 2 1.5

3 9.4 10 5 9.4 8 2 3 2.2

5 12.4 7 3 9.4 8-1/2 3 5 3.8

7 1/2 12.4 8 2-1/2 9.4 9 3 7-1/2 5.6

10 12.4 9 4 9.4 10 4-1/2 10 7.5

15 12.4 11 5 12.4 7 3 15 11.3

20 15 2 3-1/2 12.4 8 2-1/2 20 15.0

25 15 2 5 12.4 8-1/2 3 25 18.8

30 15 1 4 1/2 12.4 9 3-1/2 30 22.5

40 15 0 5 1/2 12.4 10 4 40 30.0

50 17 1-1/2 4 12.4 11 5 50 37.5

60 17 1 4 15* 3 3 60 45.0

75 19 2 4-1/2 15 2 3-1/2 75 56.3

100 21 1/2 3-1/2 15 0 3-3/4 100 75

125 21 1-1/2 4-1/2 17 2 3 125 94

150 24 2 2-1/2 17+ 2 4 150 113

200 24 2 3-1/2 19+* 2 3-1/2 200 135

250 24 1 4 19+* or 21* 0 or 2 3-1/2 or 2 250 188

300 27 1 21+* 2 3 300 225

350 27 0 21+* 1 3 350 263

400 29 1 24 3 400 300

450 29 1 24 2 450 338

500 29 1 24 2 500 375

600 29 0 27 2 600 450

700 29 0 27 1 700 525

800 29 0 27 0 800 600

900 34 1

1,000 34 1

1,250 34 0

1,500 34 0

Fill Levels (NEMA B Motors)

The Quick Selection Chart (see Figure

8) provides the correct size coupling

and fill level for any standard NEMA B

motor within the Mesur-Fil range. It

also provides the slip rate that can be

anticipated at normal operating

speed. Having the correct amount of

oil in the coupling is extremely critical

to ensure safe and proper op er a tion.

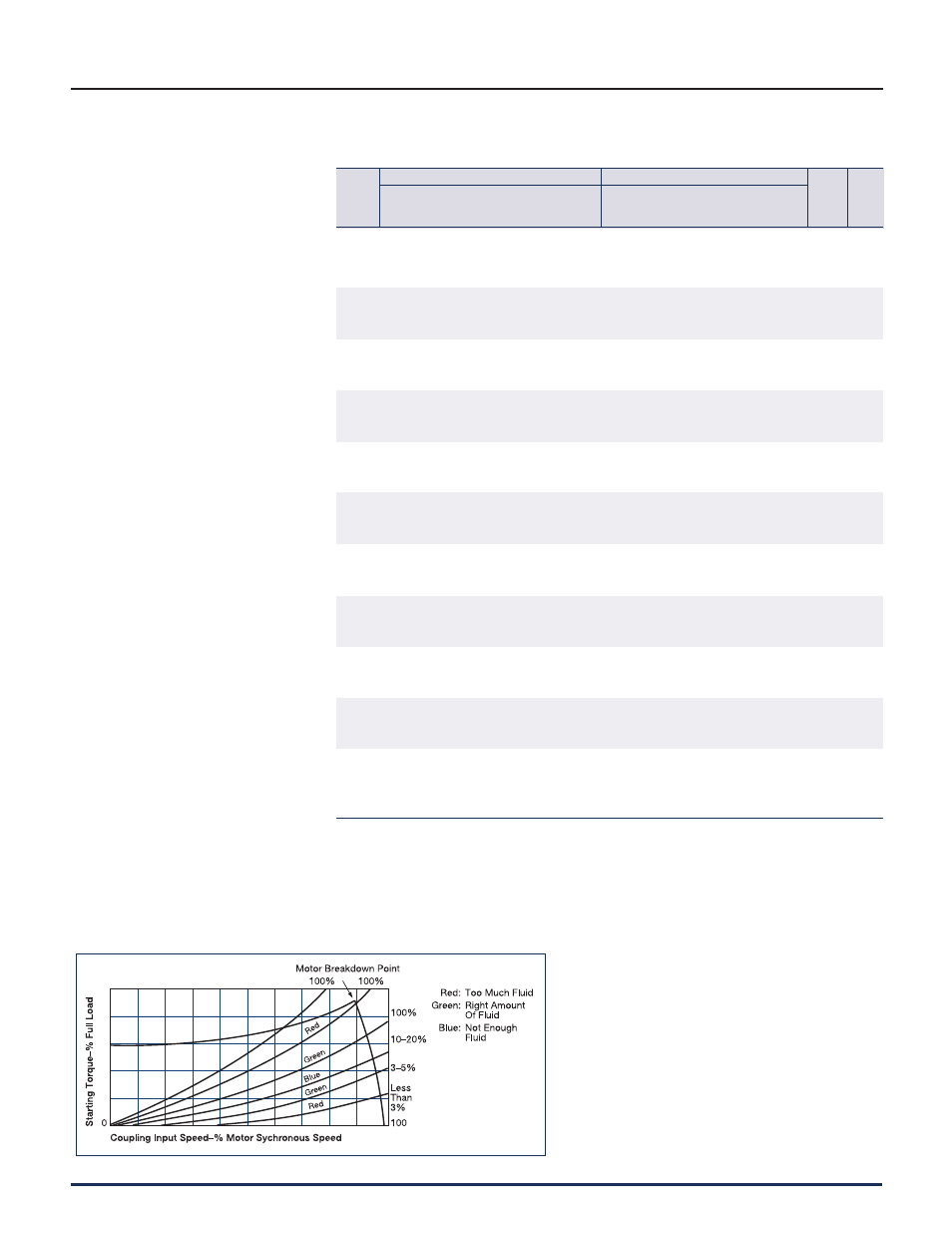

Figure 9 shows the effects of either

too much or too little fluid. With an

optimum amount of fluid, the

breakdown point of the motor with

the 100% slip line of the coupling

provide the best com bi na tion of soft

start with slip rate at normal speed.

With too much fluid (red area), the

slip rate is lower and the start is

harder. With too little fluid (blue area),

the start will be softer but the slip rate

will be much higher. This can cause

heat dis si pa tion problems, and, in

extreme situations, the coupling may

completely fail to move the load.

A choice of fluids is also avail able. In

a normal environment, petroleum oil

is the best fluid to use. For

hazardous con di tions such as those

encountering dust, paint spray, etc., a

special fire-resistant fluid may be

required.

Figure 8 Quick Selection Chart

Figure 9 Coupling Fill Effect

* In these applications, coupling will develop

stall torque somewhat higher than motor

breakdown torque.

+ In these applications, frequent starts or

overloads may overheat coupling. Use only for

loads at or below rated torque of motor with

infrequent starts.

• Caution! 7% or higher slips may cause over -

heat ing if coupling is cycled too rapidly.

For minimum operating temperature below -

10° F, consult the factory.

Note: For vertical mounting order unit with both

the standard and optional fill plugs on both sides

of the unit.

Delay chamber is recommended

for the following applications:

Overland conveyors

Blowers/Fans

Mixers

Crushers

Excavators

Mills

Large inertia drives

Centrifuges

Selection and Sizing