Mesur-fil fluid couplings, Design avantages – Wichita Clutch Fluid Coupling User Manual

Page 3

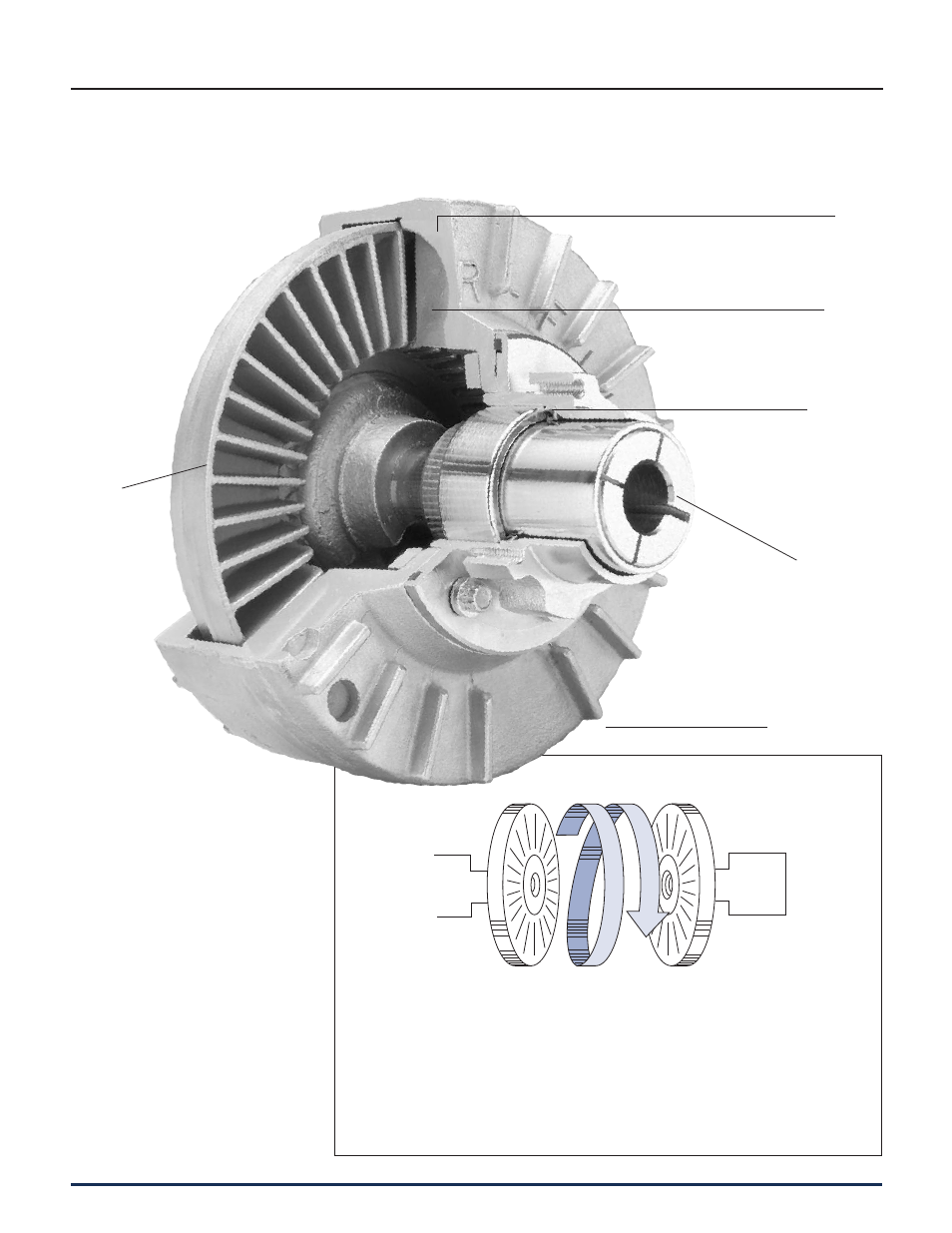

Mesur-Fil Fluid Couplings

156

Wichita Clutch 800-964-3262

P-1100-WC 1/12

Ben e fits

Mesur-Fil Fluid Couplings offer several

advantages:

•

Reduced energy consumption

•

Jam/overload protection

•

Shock load cushioning

•

No metal-to-metal contact

•

Wide range of available mount ing

options

•

High temperature Viton seals

•

Available from over 700 Formsprag

Authorized Distributors.

High Temperature

Viton Seals

Collet

Mounted

For Ease

of Mount ing

Smaller Sizes

One Piece Construction

(smaller sizes)

Eliminates Leaks.

Mesur-Fil Fluid Couplings allow motors to start

unloaded and to reach operating speed with smooth,

controlled accel eration. This makes it ideal for

ap pli ca tions with high inertia loads. They are

available in either constant or delay fill versions.

There are three primary com po nents

to Mesur-Fil Fluid Cou plings:

1. Vaned runner

2. Vaned impeller

3. Fluid fill

Torque, produced by the prime mover

(motor) acting on a vaned runner, is

transmitted through the flow of fluid into

the chambers formed by the two coupling

halves. The oil (fluid) is sub se quent ly

thrown into the vaned impeller connected

to the load causing it to turn. It is

important to note, that as this trans mis sion

of power takes place, there is virtually no

wear on the transmitting parts be cause

there is no mechanical contact between

them.

Impeller

Runner

Fluid

OUTPUT

INPUT

Prin ci ple of Operation

Runner

All Aluminum

Housing for

Low Rotating

Inertia

Impeller

Motor

Load

Design Avantages