Troubleshooting, Radial and overhung loads, Repair parts – Viking Pump TSM615: In-line Gear Reducers User Manual

Page 4

SECTION TSM 615

ISSUE

I

PAGE 4 OF 5

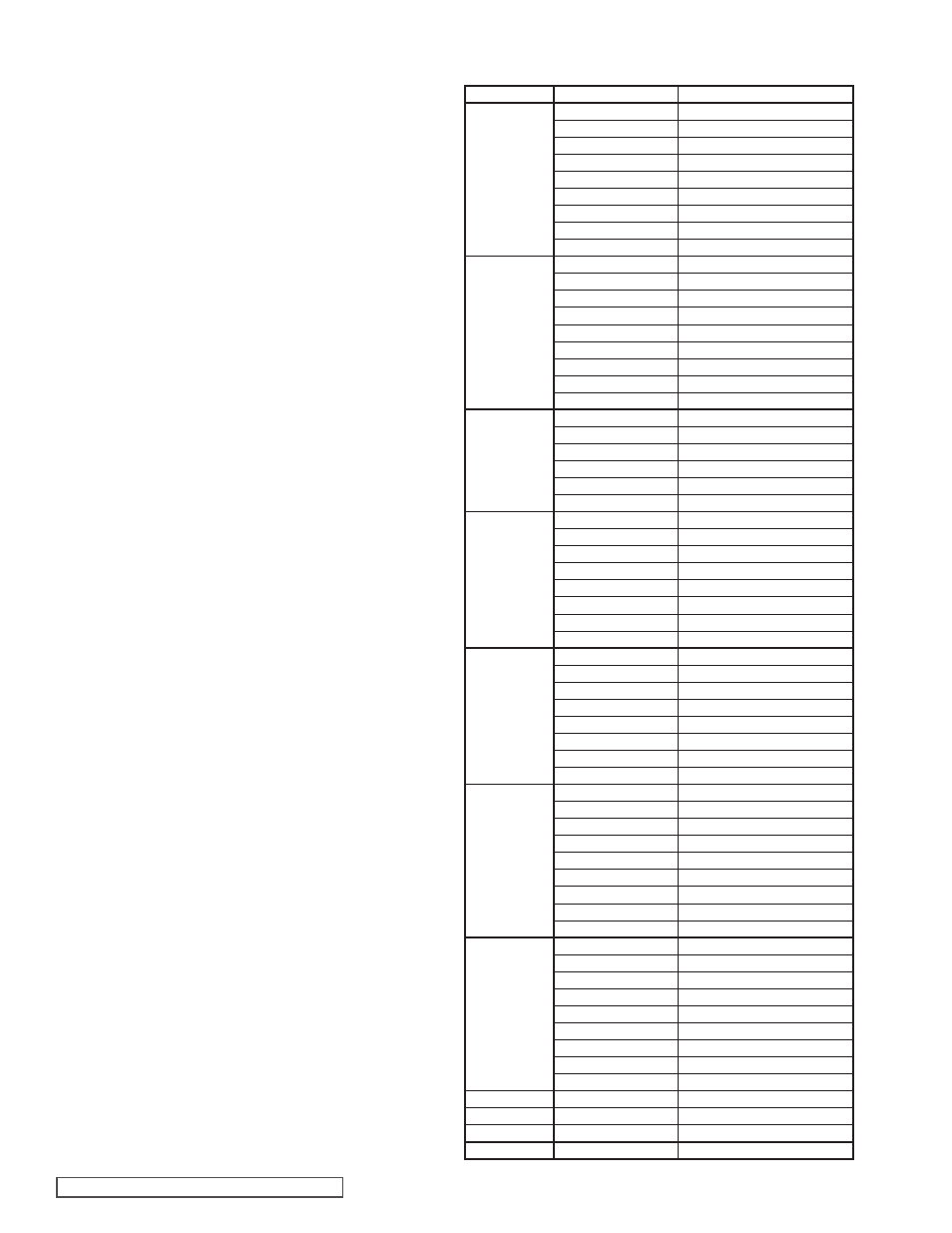

REPAIR PARTS

Special tools and training are required to repair multi-

reduction gearboxes. Replacement of gears, shafts and

bearings, combined with labor makes repairs impractical.

Oil seals and gaskets can be easily replaced without special

tools or training.

Repair parts for in-line reducers are limited to seal kits

consisting of oil seals and gaskets. Table 4 lists the part

number for the repair kit for each reducer size and

configuration.

TROUBLESHOOTING

Some of the following may help pinpoint the problem:

Bearing temperature is too high:

• Oil level is too low

• Oil is old

• Bearings are worn¹

Operating temperature is too high:

• Oil level is too high

• Oil is old

• Impurities or contaminates are in the oil

Excessive running noise:

• Gears are damaged¹

• Bearing axial backlash is too high¹

• Bearings are worn¹

• Service load is too high

• Impurities or contaminates are in the oil

Excessive noise at the gear unit mounting:

• Mounting bolts are loose

• Mounting bolts are worn

Oil leakage:

• Oil level is too high

• Casing/coupling seals worn

• Gaskets worn

Gear unit does not run or runs with difficulty:

• Oil viscosity is too high

• Oil level is too high

• Service load is too high

Output shaft does not turn with motor running

• Gears are damaged¹

¹ Sizes 51-100: Replace gear subassemblies or bearings,

see

“Repair Parts”. Sizes 12-41: Replace entire unit.

Table 4

RADIAL AND OVERHUNG LOADS

Input and output shaft of the speed reducer can be subject

to loading generated by the type of transmission fitted on

the shaft itself. Acceptable overhung load levels can be

calculated. Contact your Authorized Distributor or Viking

Technical Support for assistance.

Size

Input Shaft

Repair Kit No.

12

Solid Shaft

3-462-ILINE12-001

56C

3-462-ILINE12-002

143/145TC

3-462-ILINE12-003

182/184TC

3-462-ILINE12-004

63 IEC

3-462-ILINE12-005

71 IEC

3-462-ILINE12-006

80 IEC

3-462-ILINE12-007

90 IEC

3-462-ILINE12-008

100/112 IEC

3-462-ILINE12-009

22

Solid Shaft

3-462-ILINE22-001

56C

3-462-ILINE22-002

143/145 TC

3-462-ILINE22-003

182/184 TC

3-462-ILINE22-004

63 IEC

3-462-ILINE22-005

71 IEC

3-462-ILINE22-006

8O IEC

3-462-ILINE22-007

90 IEC

3-462-ILINE22-008

100/112 IEC

3-462-ILINE22-009

32

Solid Shaft

3-462-ILINE32-001

143/145 TC

3-462-ILINE32-002

182/184 TC

3-462-ILINE32-003

80 IEC

3-462-ILINE32-004

90 IEC

3-462-ILINE32-005

100/112 IEC

3-462-ILINE32-006

36

Solid Shaft

3-462-ILINE36-001

143/145 TC

3-462-ILINE36-002

182/184 TC

3-462-ILINE36-003

213/215 TC

3-462-ILINE36-004

80 IEC

3-462-ILINE36-005

90 IEC

3-462-ILINE36-006

100/112 IEC

3-462-ILINE36-007

132 IEC

3-462-ILINE36-008

41

Solid Shaft

3-462-ILINE41-001

143/145 TC

3-462-ILINE41-002

182/184 TC

3-462-ILINE41-003

213/215TC

3-462-ILINE41-004

80 IEC

3-462-ILINE41-005

90 IEC

3-462-ILINE41-006

100/112 IEC

3-462-ILINE41-007

132 IEC

3-462-ILINE41-008

51

Solid Shaft

3-462-ILINE51-001

182/184 TC

3-462-ILINE51-002

213/215 TC

3-462-ILINE51-003

254/256 TC

3-462-ILINE51-004

284/286 TC

3-462-ILINE51-005

100/112 IEC

3-462-ILINE51-006

132 IEC

3-462-ILINE51-007

160 IEC

3-462-ILINE51-008

180 IEC

3-462-ILINE51-009

61

Solid Shaft

3-462-ILINE61-001

182/184 TC

3-462-ILINE61-002

213/215TC

3-462-ILINE61-003

254/256 TC

3-462-ILINE61-004

284/286 TC

3-462-ILINE61-005

100/112 IEC

3-462-ILINE61-006

132

3-462-ILINE61-007

160

3-462-ILINE61-008

180

3-462-ILINE61-009

70

Solid Shaft

3-462-ILINE70-001

80

Solid Shaft

3-462-ILINE80-001

90

Solid Shaft

3-462-ILINE90-001

100

Solid Shaft

3-462-ILINE100-001