Caution, Danger – Viking Pump TSM443: K-LL 4205-G LP Gas User Manual

Page 4

SECTION TSM 443

ISSUE

C

PAGE 4 OF 8

CaUTION !

WhEN ThE hEaD IS BEING REMOVED

FROM ThE PUMP ThE IDlER USUallY

STaYS ON ThE IDlER PIN, BUT WIll

Fall OFF IF ThE INSIDE OF ThE hEaD

IS TIlTED DOWNWaRD.

CaUTION !

IF ThE ChECK ValVE IS lEFT OUT OF

ThE DISChaRGE SIDE OF ThE hEaD,

ThE PUMP MUST NEVER BE RUN IN

ThE OPPOSITE DIRECTION WIThOUT

INSTallING a NEW ChECK ValVE.

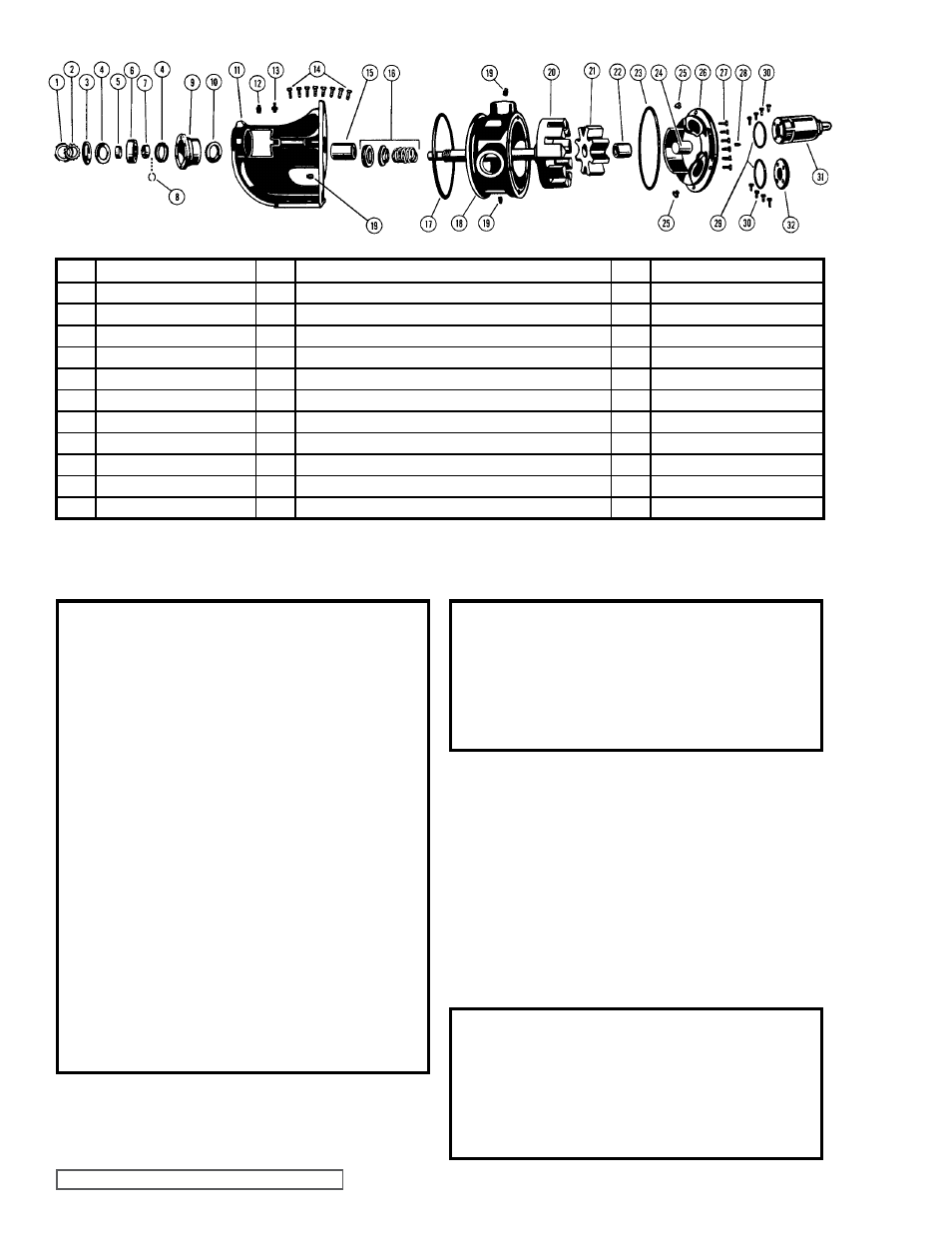

FIGURE 2

Exploded View Series 200G & 260G Pumps

ITEM

NaME OF PaRT

ITEM

NaME OF PaRT

ITEM

NaME OF PaRT

1

Locknut

12

Pressure Relief Plug

23

O-Ring Gasket, Head

2

Lockwasher

13

Grease Fitting

24

Idler Pin

3

End Cap, Bearing Housing

14

Capscrew, Bracket

25

Check Valve

4

Closure Bearing Housing

15

Bracket Bushing (Needle Bearing and Snap Ring on KK-250G Only) 26

Head (Valve Type) and Idler Pin

5

Bearing Spacer Collar

16

Mechanical Seal

27

Capscrew for Head

6

Ball Bearing

17

O-Ring Gasket, Back Flange

28

Pipe Plug

7

Bearing Spacer Collar, Recessed

18

Casing

29

O-Ring Valve Gasket

8

Keeper Ring Halves

19

Pipe Plug

30

Capscrew for Valve and Cover Plate

9

Bearing Housing with Setscrews

20

Rotor and Shaft

31

Return-To-Tank Relief Valve

10

Closure for Seal Chamber

21

Idler

32

Cover Plate

11

Bracket

22

Idler Bushing

DaNGER !

Before opening any Viking pump liquid

chamber (pumping chamber, reservoir, relief

valve adjusting cap fitting etc.) Be sure:

1. That any pressure in the chamber has

been completely vented through the

suction or discharge lines or other

appropriate openings or connections.

2. That the driving means (motor, turbine,

engine, etc.) has been “locked out” or

made non- operational so that it cannot

be started while work is being done on

pump.

3. That you know what liquid the pump

has been handling and the precautions

necessary to safely handle the liquid.

Obtain a material safety data sheet

(MSDS) for the liquid to be sure these

precautions are understood.

Failure to follow above listed precautionary

measures may result in serious injury or

death.

1. Remove the head from the pump Avoid damaging the

O-ring head gasket If the pump has a relief valve on

the head, the valve may be removed, but this is not

necessary

Always keep your feet in the clear should this part fall A fall

on a hard surface can damage the idler If the idler should

fall, check carefully and file or stone all nicked or rough places

before re-assembly

Using a pencil, inspect the check valves located at the base

of the idler pin in the head (See Figure 3) The ball on the

inside of these fittings should be depressed with the point of

the pencil to insure that the valve is not stuck If the spring

behind the ball does not hold the ball in a closed position, or if

the spring is broken, remove the check valve from the head

If a defective check valve is removed from the discharge side

of the head, it need not be replaced and can be discarded