Assembly – Viking Pump TSM410.1: F-FH 4625 User Manual

Page 4

SECTION TSM 410 1

ISSUE

D

PAGE 4 OF 5

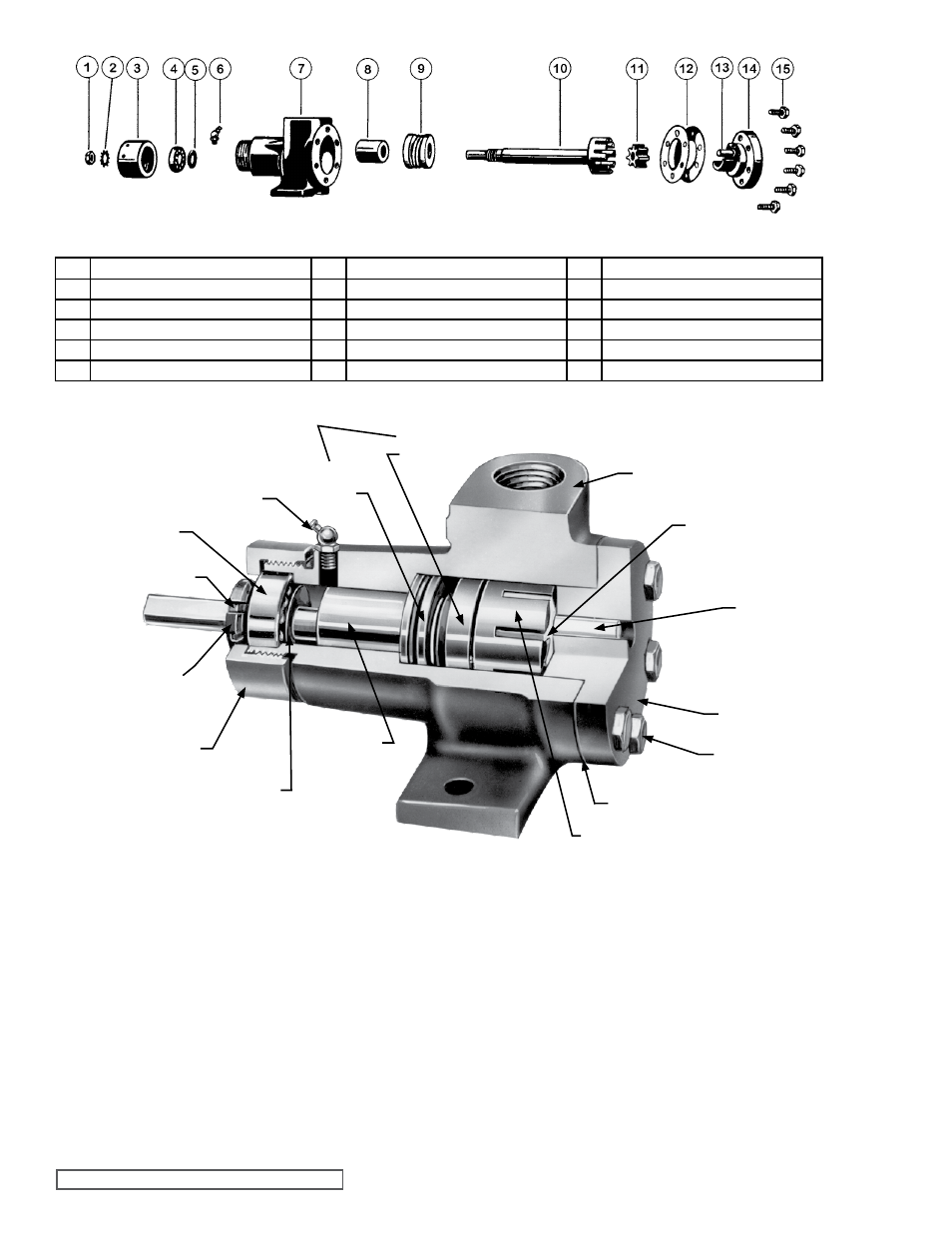

FIGURE 3

CUTaWaY VIEW OF SERIES 4625

ITEM

NaME OF PaRT

ITEM

NaME OF PaRT

ITEM

NaME OF PaRT

1

Locknut

6

Grease Fitting

11

Idler

2

Lockwasher

7

Casing

12

Head Gaskets

3

Packing Nut

8

Casing Bushing

13

Idler Pin

4

Ball Bearing

9

Mechanical Seal

14

Head

5

Washer, Bearing Retainer

10

Rotor and Shaft

15

Capscrews

FIGURE 2

ExPlODED VIEW SERIES 4625

All parts should be examined for wear before the pump is

put together When making major repairs, such as replacing

a rotor and shaft, it is advisable to install a new casing

bushing

INSTallING CaSING bUSHING - The casing bushing

can be replaced in the following manner: Insert a bar

approximately 9375” diameter and at least 3 5” long in the

seal end of the casing and press the bushing out of the

casing When installing a new bushing, an arbor press

should be used Coat the bushing with light lube oil and press

the bushing into the bore from the head end The bushing

aSSEMblY

should be positioned so that the face of the bushing is 0625”

below the surface of the step machined for the seal seat, see

Figure 4.

1. Clean all parts thoroughly

2. Coat the complete seal seat with light oil and install

it into the casing Make sure that the pins on the

backside of the seat go into the slots provided for

them in the casing (Putting a light pencil line in the

bore of the seal seat in line with the pins will help

keep the pins in proper alignment with the holes)

3. Coat the rotor shaft with light oil Slide the

mechanical seal wave spring onto the shaft Coat

GREaSE

FITTING

CaSING

ball

bEaRING

WaSHER

(bEaRING RETaINER)

MECHaNICal

SEal

lOCKNUT

lOCKWaSHER

ROTaRY

MEMbER

CaSING

bUSHING

IDlER

HEaD

IDlER PIN

PaCKING

NUT

SEal

SEaT

HEaD

GaSKETS

ROTOR

& SHaFT

CaPSCREW