Installation, Mounting, Alignment – Viking Pump TSM1470: HI-LO Double Pumps User Manual

Page 3: Danger, Piping/hose

SECTION TSM

1470

ISSUE

F

PAGE 3 OF 8

Mounting

1. Surfaces to which the pump mounts against must be

clean and flat.

2. Use SAE Grade 5 or better capscrews to mount the

pump.

3. The 4 mounting capscrews for GP-04 and GP-05 pumps

must have a minimum of ½ inch engagement and must

be torqued evenly to 12-15 ft.-lbs.

4. The 2 mounting capscrews for the SG-07 pumps must

have a minimum of ½ inch thread engagement and must

be torqued evenly to 50-55 ft.-lbs.

5. Do not strike or press the pump drive coupling half to

install on the pump shaft. Damage to the pump or

coupling may result. If the coupling does not slide onto

the pump shaft, inspect the coupling bore, shaft and key

for nicks or burrs and remove if present.

6. Once the pump has been mounted, place a small amount

of compatible liquid into the suction port and turn by hand

to ensure the pump turns freely.

Alignment

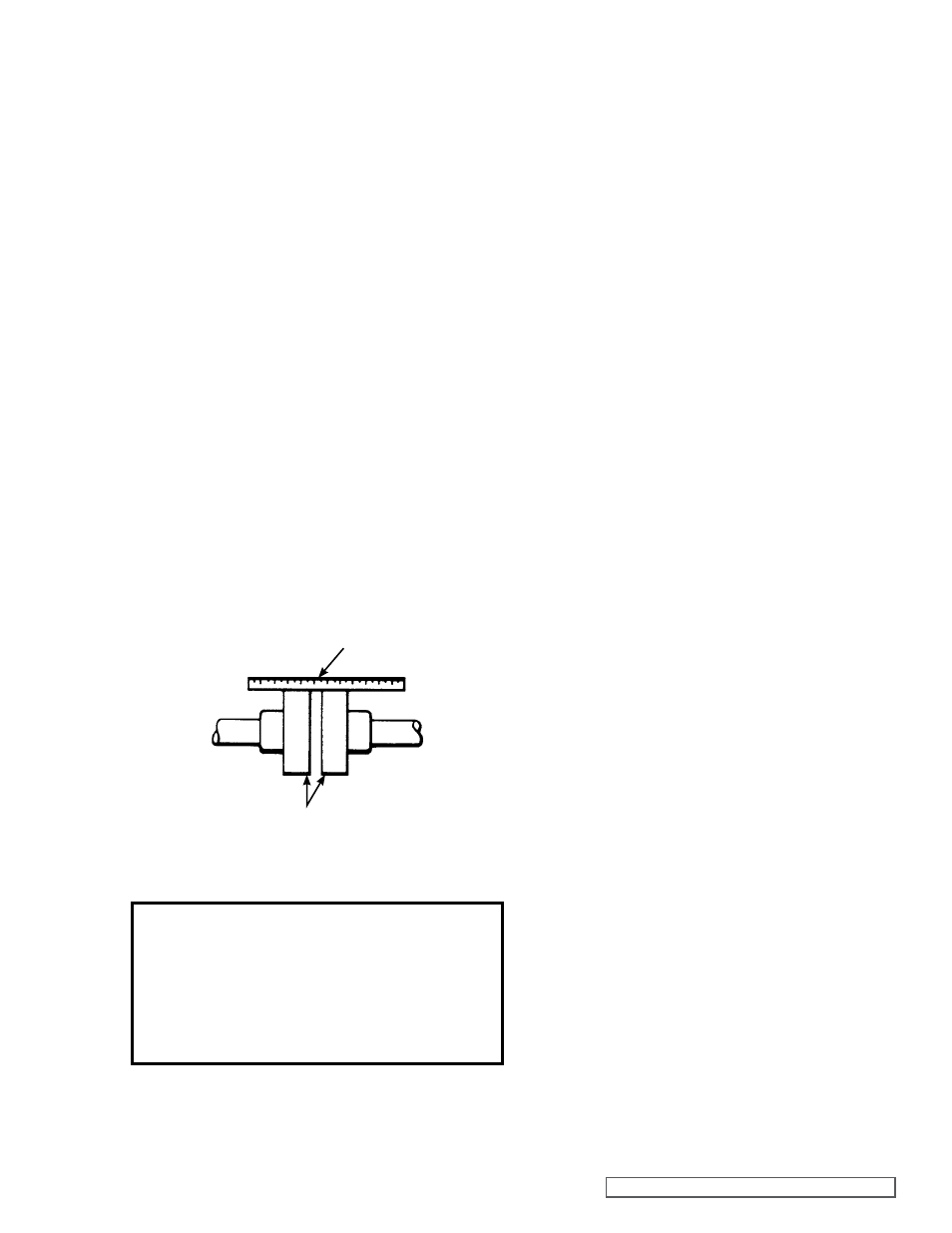

Check alignment after mounting.

If the unit has a flexible coupling, remove any coupling guards

or covers and check alignment of coupling halves. A straight

edge (a piece of key stock will work) across the coupling

must rest evenly on both rims at the top, bottom and sides.

See Figure 3.

Danger !

before starting pump, be sure all drive equipment

guards are in place.

Failure to properly mount guards may result in seri-

ous injury or death.

Piping/Hose

The cause of many pumping problems can be traced to the

suction piping. It should always be as large in diameter and

as short in length as possible.

Before starting the layout and installation of your piping

system, consider the following points:

1. Never use piping smaller than the pump port

connections. Piping larger in diameter than the port

connection is sometimes required to reduce friction

losses.

2. Be sure the inside of the pipe is clean before installing.

3. Do not use galvanized piping.

4. When approaching an obstacle in the suction line,

go around instead of over it. Going over an obstacle

may create an air pocket. Where practical, slope the

piping so no air or liquid pockets will be formed. Air

pockets in the suction line make it hard for the pump

to prime.

5. Viking recommends using a strainer on the suction

side of the pump. The strainer will keep foreign

objects from going into the pump. A 100 mesh

strainer is recommended. Provisions must be

made for cleaning the strainer. Use of a strainer is

particularly important at start up to help clean the

system of weld beads, pipe scale and other foreign

objects.

6. On a hydraulic system, it is recommended that a

return line filter be installed having a maximum 10

micron rating.

7. A pressure relief valve is required in the discharge

line. See

Pressure Relief Valves, General page 1

item 7.

8. The pump must not be used to support piping.

Weight of the pipe must be carried by hangers,

supports, stands, etc.

9. When fastening to the pump do not impose any

strain on the pump casing. “Springing” or “drawing”

piping up to the pump will cause distortion, possible

misalignment and probable rapid wear of the pump.

Do not use the pump to correct errors in the piping

layout or assembly.

10. All joints of piping system must be tight; liquid thread

sealant will help assure leak free threaded joints.

Loose joints result in liquid leaks or suction side

leaks. Air leaks make the pump noisy and reduce

flow.

CAUTION: Be careful not to over tighten

fittings as this can cause cracked joints. Do not use

PTFE / plumber’s tape. Reduced friction makes

over tightening very easy and will result in cracked

ports.

11. Drive alignment must be checked after the piping is

hooked up.

INSTALLATION

USE STRAIGHT EDGE.

THESE SURFACES

MUST BE PARALLEL.

CHECK WIDTH BETWEEN THESE SURFACES WITH INSIDE CALLIPERS OR FEELER

GAUGE TO BE CERTAIN THE FACES ARE EQUAL DISTANCE APART AND PARALLEL.

FIGURE 3