Triton SJA 300 User Manual

Page 8

7

GB

Notes:

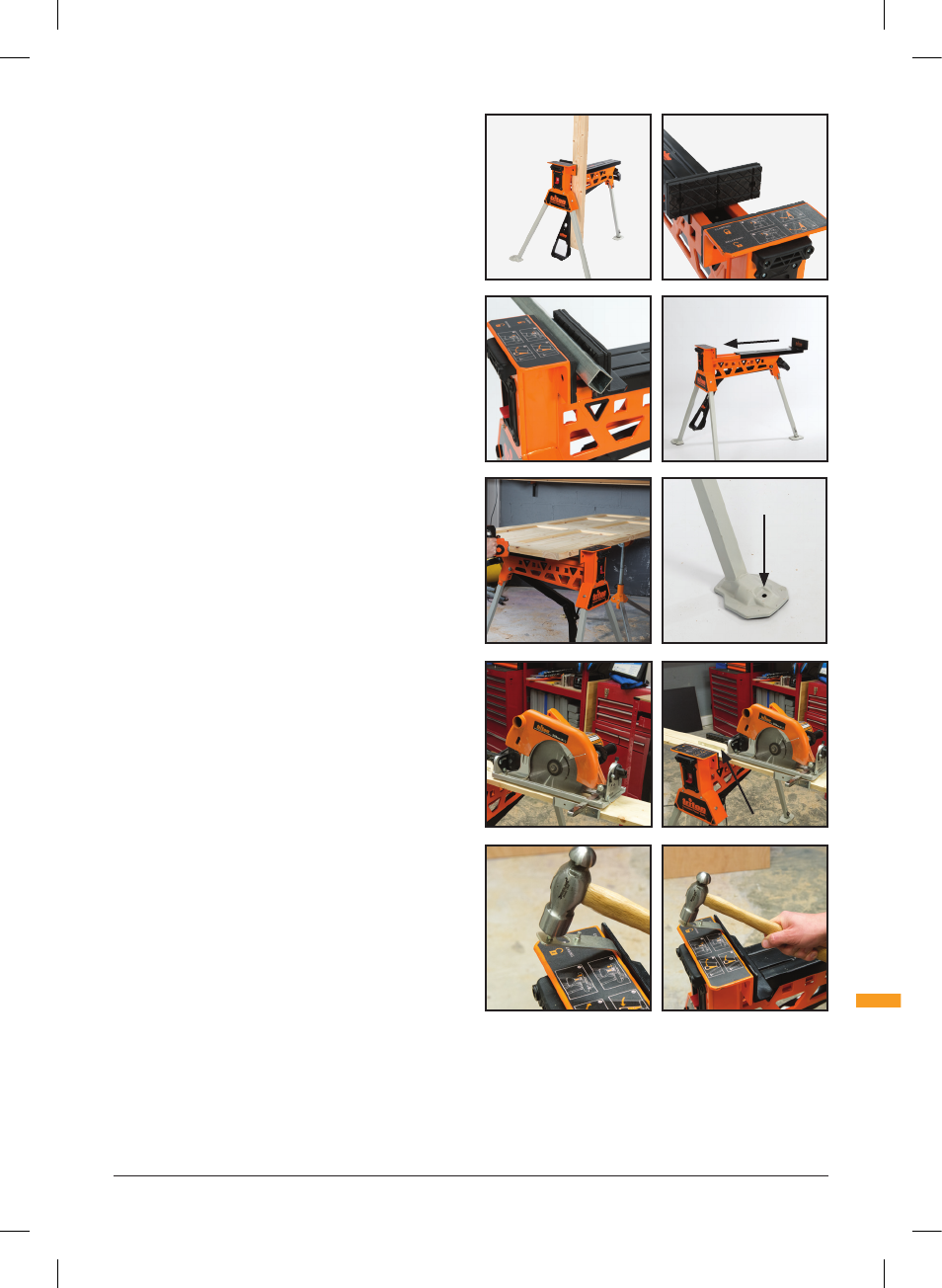

• If clamping on one side of the jaws only, as shown in

fig 16, reduce the maximum clamping pressure used

to avoid uneven clamping. Alternatively use another

workpiece of the same material and size on the other

side to prevent the jaw mechanism being warped by

uneven pressure

• If necessary, to prevent damage to the surface of the

workpiece, use a softer material between the jaw pads

and workpiece, for example wood or a layered fabric

material

• If the workpiece has sharp edges, you will need to

protect the jaw pads, or remove them when clamping

• If you are using SuperJaws indoors, on flooring that

could be marked by the combined weight of the

SuperJaws and the workpiece, use additional pieces

of wood or another material between the feet and the

floor, to spread the weight and prevent marking

• The jaw pads have vertical and horizontal grooves that

allow for square tube and angled workpieces to be

clamped more securely, as shown in Fig 17a and Fig

17b. Fig 17b shows square tube securely clamped in

the ideal position for sawing into the corner first

• If the jaw pads become worn, replacement pads are

available from your Triton stockist

• The Moving Jaw (2) can be fully removed and re-fitted

in reverse, as shown in Fig 18, to allow for clamping

level workpieces of 450-1000mm in size.

Do not try to clamp large, uneven workpieces that may

force the moving jaw to bend/warp as it clamps.

The workpiece should sit level on the top surface

between the jaws, as shown in Fig 18b

• When clamping very long or large workpieces that may

overbalance SuperJaws, note that the two front feet

have individual holes that can be used to secure the

feet against a surface with screws or pegs to increase

stability, as shown in

Fig 19

Ripping a Plank

• When ripping a plank, stop the cut before reaching the

jaws

• Remove the workpiece and re-clamp with sufficient

amount of the cut beyond the jaws, so that you can

drop in your saw to recommence the cut

• Before clamping, insert a spacer which is slightly

thicker than your saw cut, at the jaw area, to keep the

cut open, as indicated in Fig 20b

Operation

Fig.16

Fig.17a

Fig.17b

Fig.18b

Fig.18a

Fig.19

Fig.20a

Fig.21a

Fig.21b

Fig.20b

SJA300_Z1MANPRO1.indd 7

12/08/2014 14:54