Corrosion control, Parts list, Preventing oxidation – tekmar M3061 Mixing Valve Adapter Kit User Manual

Page 3: Raising the ph level of the water, Reducing galvanic corrosion, Using a corrosion resistant heat exchanger, Adding a corrosion inhibitor

3 of 4

Copyright © D 016 -10/00

Corrosion occurs when metals are placed in a liquid environment in which the liquid has a high oxygen or mineral content or the liquid

is very acidic. Factors such as temperature and flow rate affect the rate at which the corrosion occurs.

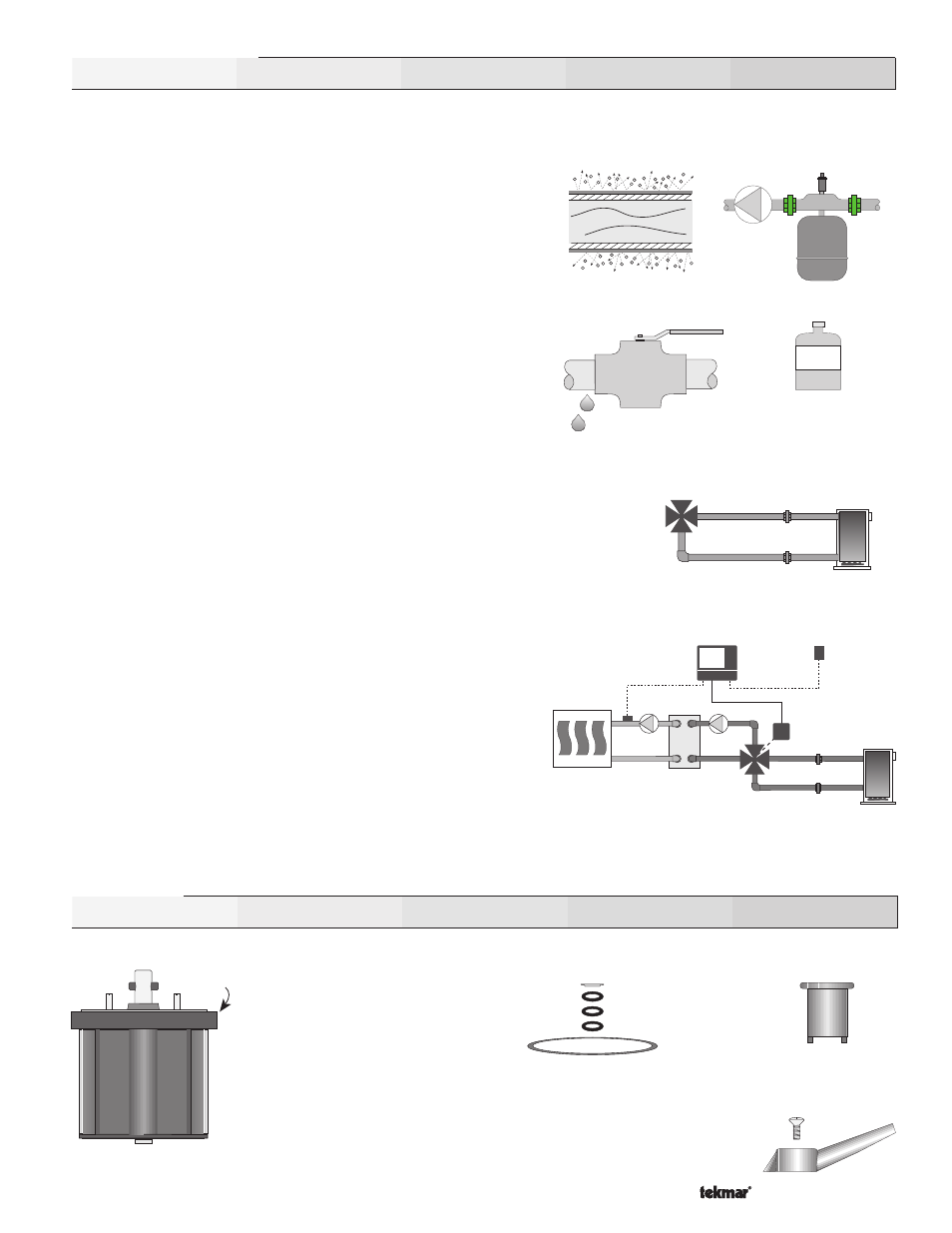

Preventing Oxidation

Oxidation results when oxygen dissolved in the water reacts with the

iron to form ferric hydroxide (rust). When a closed hydronic system is

filled with fresh water, oxidation occurs until the oxygen is consumed.

It is important to prevent new oxygen from entering the system and

continuing the oxidation process. The most common sources of oxy-

gen include oxygen diffusion through pipe materials and the continu-

ous addition of make up water due to leakage from the system. Fresh

air and oxygen may also enter the system if a negative pressure exists

due to an incorrect placement of the pump and expansion tank. If new

oxygen cannot be prevented from entering the system, chemical

treatments such as oxygen scavengers must be used. It is important to

note that the use of chemicals requires periodic maintenance.

Raising the pH Level of the Water

Water with a pH of less than 4.5 (acidic) greatly accelerates the corrosion

of iron and steel. One method of reducing corrosion of iron in a closed

system is to increase the pH level to produce an alkaline solution. A

water treatment specialist should be consulted for more information on

the available chemical treatments for adjusting the pH level.

Reducing Galvanic Corrosion

Galvanic corrosion results when different metals are use in the same piping network. The

mixing valve is commonly used in both copper and mild steel (black iron) piping systems.

Mild steel pipe does not cause cast iron to corrode and is the recommended piping

material for use with the mixing valve. When a small amount of cast iron is placed in a large

copper piping network, the cast iron corrodes quickly. Sections of the copper pipe can be

replaced with mild steel pipe to reduce the severity of the corrosion. Mild steel generally

corrodes more quickly than cast iron and therefore the pipe is sacrificed for the valve.

Dielectric unions can also be used to separate ferrous and copper materials in order to

reduce corrosion of the iron components.

Using a Corrosion Resistant Heat Exchanger

Heat exchangers which have a corrosion resistant liner or which are

manufactured from stainless steel can be used to isolate the cast iron

mixing valve from corrosive components. The heat exchanger is

typically used to separate oxygen permeable pipe or copper pipe from

ferrous components. A heat exchanger with a high rate of heat transfer

(Btu per hour) is recommended to prevent the valve from oscillating.

A plate type heat exchanger is typically used.

Adding a Corrosion Inhibitor

A variety of corrosion inhibitors are available which can help prevent corrosion in the system. In systems which require an

antifreeze, the corrosion inhibitor may be included as part of the antifreeze solution. For more information, it is best to consult the

individual companies who manufacture corrosion inhibitors.

Corrosion Control

type 016, 1"

– Part # M3022

type 017, 1 1/4" – Part # M3022

type 018, 1 1/2" – Part # M3022

type 019, 2"

– Part # M3022

type 024, 2 1/2" – Part # M3023

type 025, 3"

– Part # M3024

type 026, 4"

– Part # M3024

type 016, 1"

– Part # M3017

* type 017, 1 1/4" – Part # M3018

* type 018, 1 1/2" – Part # M3018

* type 019, 2"

– Part # M3018

type 024, 2 1/2" – Part # M3019

type 025, 3"

– Part # M3020

type 026, 4"

– Part # M3021

*Note: M3018 is also available

without the cast iron bonnet.

Order part# M3030.

Valve Handle &

Retaining Screw

Part # M3025

Seal Kit

(includes 3 x "O" rings, retainer, gasket)

Parts List

Make sure there

are no leaks

Always pump

away from

the expan-

sion tank.

If oxygen continues

to remain within the

system, use an oxy-

gen scavenger.

Oxygen

Scavenger

XXX

BOILER

MIXING

VALVE

To reduce localized corrosion in the mixing

valve, install steel pipe between the boiler and

the mixing valve.

M

Heating

System

tekmar

Mixing

Control

Corrosion

Resistant Fast

Acting Heat

Exchanger

Iron Components

Components

Causing Corrosion

When using plastic pipe,

an oxygen diffusion barrier

is often available.

Coupling Kit

Part # M3029

Valve Flap Assembly

(includes bonnet, gasket,

3 x "O" rings, retainer)

Cast Iron

Bonnet