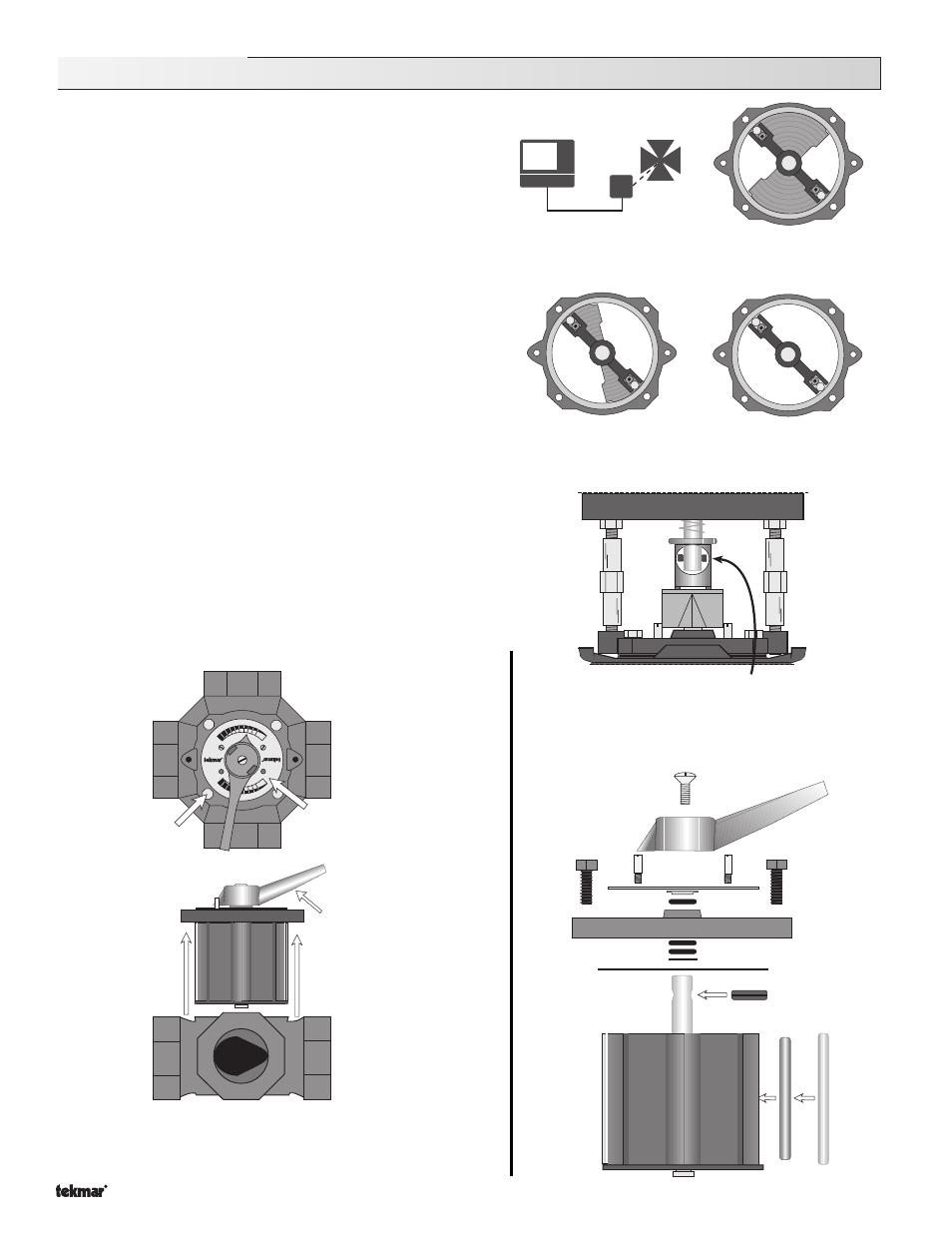

Valve maintenance, Cleaning the mixing valve exploded view, All valve parts less cast iron body – tekmar M3061 Mixing Valve Adapter Kit User Manual

Page 2: Mixing valve actuating motor

2 of 4

Copyright © D 016 -10/00

The body of the tekmar mixing valve is constructed from cast iron which

has been found to be the most economical and suitable material for the

high stress environment in which the valve operates. As with all ferrous

components in a hydronic system, certain precautions are required in

order to prevent any appreciable corrosion from occurring. When the

mixing valve is used with a tekmar mixing reset control, the control

ensures that the valve is fully opened and fully closed every three days.

During this exercising period, a stainless steel roller seal scrapes the

corrosion products off the inside of the valve in order to prevent the valve

flap from seizing.

In some automatic systems, an exercising function is not provided and

the mixing valve flap is not rotated through its full range. A build up of

corrosion outside the normal range of motion can result in the valve flap

jamming when a greater movement is required. This is typically found in

systems where the valve is oversized for most of the heating season and

is then required to supply additional heat on a very cold day. One

indication of a seized valve flap is a broken shear pin on the actuating

motor shaft or a broken coupling. Before replacing the shear pin or

coupling, carefully disassemble and clean the valve. If corrosion is not

evident, ensure the system is free from any foreign material that may

have lodged in the valve.

Note: Damage to the valve due to foreign objects or excessive corrosion

is not covered under warranty.

When the mixing valve is used manually, adequate corrosion control

must be provided and the valve flap should be rotated through its full

range on a regular basis in order to prevent seizure. If the valve flap does

become jammed, do not force it to move as internal components may be

damaged. A seized valve must be carefully disassembled and cleaned.

To disassemble the valve, remove the 4 bonnet bolts and carefully pull

the flap assembly out of the valve body.

Valve Maintenance

To reduce the possibility of dam-

age to the valve, install a tekmar

Mixing Control with an “exercis-

ing function”.

When the valve flap is exercised regu-

larly, the full range of motion of the

mixing valve remains free of corrosion.

Corrosion build up within a valve

due to poor water quality and a

limited range of valve flap motion.

Corrosion buildup within a manual

valve due to poor water quality and

infrequent valve flap movement.

After removing the flap assembly, carefully remove rust and scale from

the valve body and flap assembly using steel wool or emery cloth. The

valve should be lubricated with a waterproof high temperature grease

before it is reassembled.

Use the valve handle

to

carefully

pull the flap

assembly

straight

out

from the valve body.

9

8

7 6

5 4 3 2

1

2

3

4

5

6

7

8

1" valves have 4 hex

socket cap screws under

the aluminum scale plate.

Remove the 4

bonnet bolts

Cleaning the Mixing Valve

Exploded View

All Valve Parts Less Cast Iron Body

Actuating

Motor

Four Way

Valve

016 - 025

tekmar

Mixing

Control

M

Mixing Valve

Actuating Motor

Shear pin provides break point when maximum stress force is reached.

A broken shear pin is an indication that the valve has jammed.

2 x "O" Rings

"O" Ring

Retainer

Scale Plate

Handle

Handle Screw

Limit

Peg

Rubber spring

Stainless steel roller seal

Roll Pin

Valve Flap

Shaft

Bonnet Gasket

Lower "O" Ring Retainer

Bonnet

Bolt (x4)

Bonnet