Rite-Ride 2564 User Manual

Page 3

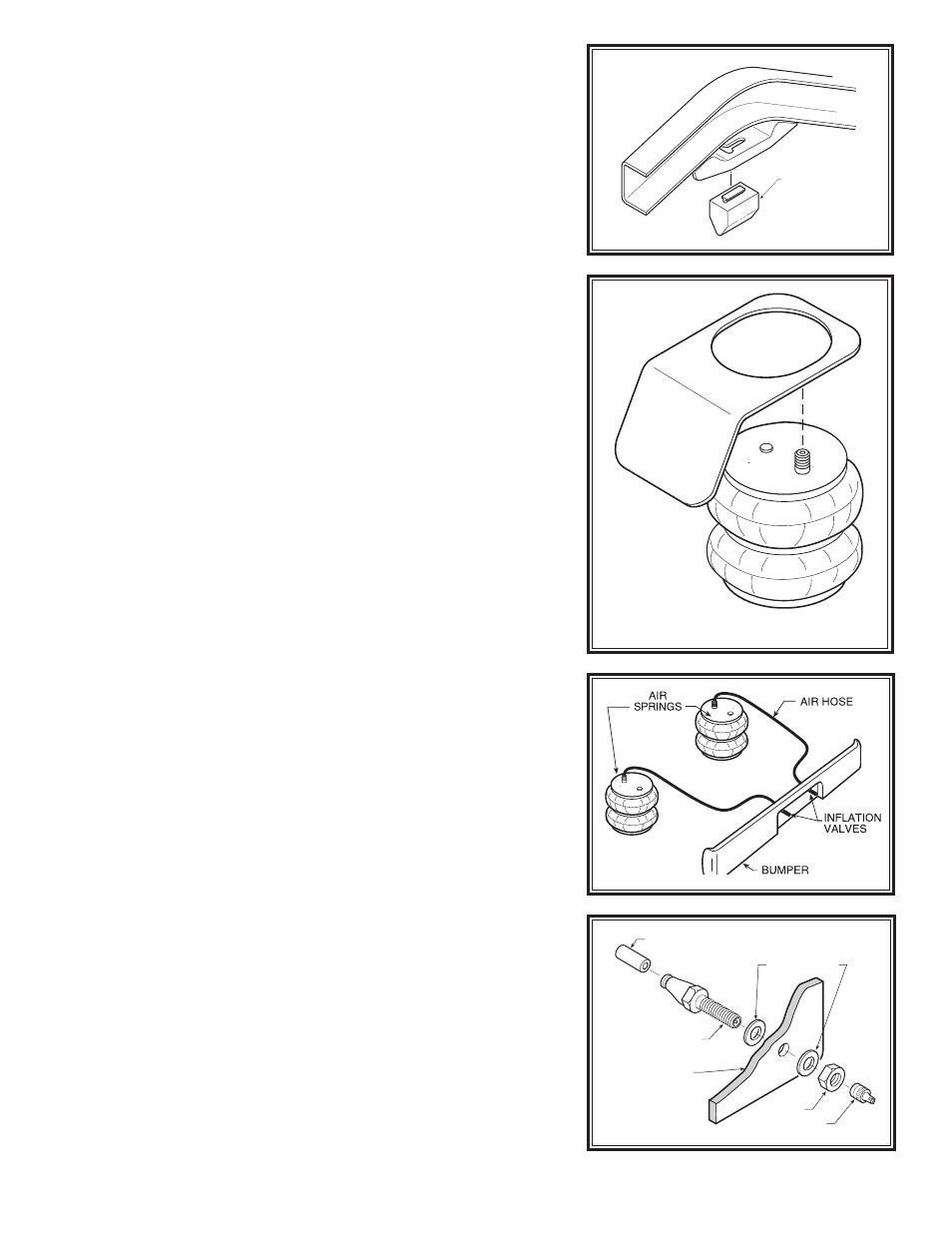

JOUNCE BUMPER

TO BE REMOVED

STEP 1—PREPARE THE VEHICLE

Make sure that the vehicle is on a solid level surface. Take neces-

sary safety precautions such as using wheel chocks when working

under your vehicle. This vehicle does not have to be jacked up to

install the kit. Remove the positive battery cable. Remove the rub-

ber jounce bumper under the frame rail, see Figure “B”.

STEP 2—PREASSEMBLE THE RIDE-RITE KIT

Select one air helper spring and one upper bracket from your kit.

Align the combo stud and pin to and place the bracket on the air

spring. Secure with a 5/8”-18 nut as shown in Figure “A”. Install

the air fitting and tighten securely to engage the orange thread

sealant. Position the lower bracket as shown in Figure “A”. Fas-

ten the lower bracket to the air helper spring using a 3/8”-16 x 3/4”

flanged hex bolt (finger tight).

STEP 3—ATTACHMENT TO THE FRAME

Position the assembly on the axle under the frame rail in the loca-

tion shown in Figure “A”. Using the 1/4”-20 hex head cap screws,

1/4” washers and nylocks, attach the upper bracket to the frame.

STEP 4—LOWER BRACKET ATTACHMENT

Position the lower bracket by pushing it up against the leaf stack.

The cutouts should clear the u-bolts for a tight fit. Install the bail

clamp around the bottom of the leaf stack, through the lower

bracket and secure with 3/8”-16 flanged lock nuts. Visually align the

air spring so that it is as vertical as possible. Once the air spring is

correctly aligned install the 3/8”-16 x 4” carriage bolts in the square

holes that allow for no interference of the lower bracket as shown in

Figure “A”. The lower bracket is then secured by the bracket strap

which is placed under the axle and fastened with 3/8”-16 flanged

lock nuts, see Figure “A”. After the lower bracket is fastened to

the axle tighten the air spring to the lower bracket making sure

the air spring remains in a vertical position.

STEP 5—INSTALLATION TO THE PASSENGER’S SIDE

ASSEMBLY

Reverse any orientations when assembling and installing the right,

or passenger, side of the vehicle. Note: The use of a heat shield

is required on the passenger’s side of the vehicle. Refer to Fig-

ure “C”. The heat shield will mount between the upper bracket and

the air helper spring. Angle the heat shield so it is placed halfway

between the air helper spring and the closest point on the exhaust.

Be sure that the heat shield will not contact any other component

as the suspension compresses. (i.e. brake lines, shock absorbers,

lower bracket assembly)

STEP 6—INSTALL THE AIR LINE AND THE INFLATION

VALVE

Uncoil the air tubing and measure to cut.

DO NOT FOLD OR

KINK THE TUBING. Try to make the cut as square as possible.

Insert one end of the tubing into the air fitting installed in the top of

the air helper spring. Push the tubing into the fitting as far as possi-

ble. Select a location on the vehicle for the air inflation valves. This

can be on the bumper or the body of the vehicle, as long as it is

protected so the valves will not be damaged. Drill a 5/16” hole and

install the air inflation valve using two 5/16” flat washers per valve

as supports. Route the tubing from the air helper spring to the infla-

tion valve, avoiding direct heat from the engine, exhaust pipe, and

away from sharp edges. The air line tubing should not be bent or

curved sharply as it may kink with time. Secure the tubing in place

with the nylon ties provided. Push the end of the air line tubing into

the inflation valve as far as possible. See Figures “D” & “E”.

FIGURE “B”

AIR LINE

PUSH-TO-CONNECT

INFLATION VALVE

FLAT WASHER

HEX NUT

VALVE CAP

BODY OF

VEHICLE

FIGURE “E”

FIGURE “D”

HEAT SHIELD

FIGURE “C”