1 - p, 2 - p, 3 - a – Rite-Ride 2320 User Manual

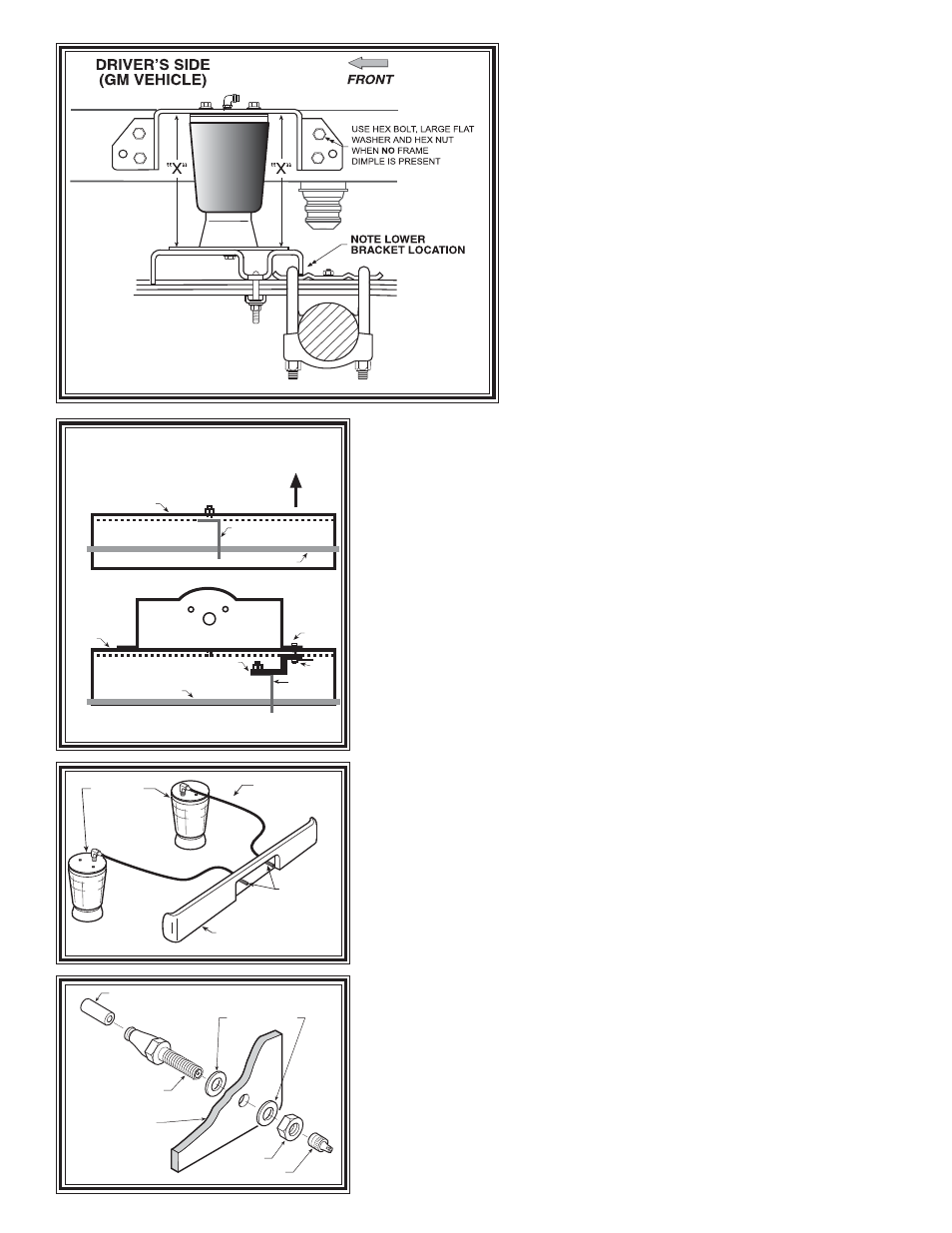

Page 4: (gm trucks)

FRAME

BRAKE LINE

EXISTING

BRAKE LINE

CLIP

FRAME

BRAKE

LINE

EXISTING

BRAKE LINE

CLIP

UPPER

BRACKET

HEX

BOLT

NUT

PLATE

BRAKE LINE

RELOCATION

BRACKET

BRAKE CLIP RELOCATION

(FORD VEHICLE ONLY)

WHEEL

“X” = 7.25” - 9”

BRACKET SHOULD BE

AS HIGH AS POSSIBLE

WITHIN THIS RANGE.

AIR LINE

PUSH-TO-CONNECT

INFLATION VALVE

FLAT WASHER

HEX NUT

VALVE CAP

BODY OF

VEHICLE

Figure "B"

S

TEP

1 - P

REPARE

THE

VEHICLE

First, measure the distance between the tire

and frame. If there is less than 6" of clearance, do

not proceed. There should be no extra weight in

the bed of the truck so that the initial ride height of

your air helper spring kit will be correct. With the

vehicle on a solid, level surface chock the front

wheels. Raise the vehicle by the axle and remove

the rear wheels. After the removal of the wheels,

lower the vehicle so the axle rests on jack stands

rated for your vehicles weight. Remove the nega-

tive battery cable.

THE “X” DIMENSION.

Throughout this manual we refer to an “X”

dimension. This is the initial, un-inflated over-

all height of the air spring. Both right and left

sides should be installed at the same height.

The “X” dimension on this air spring is 7.25"to

9". The upper bracket shopuld be as high as

possible within this range.

The air spring may require some stretch-

ing to achieve this dimension.

S

TEP

2 - P

RE

-

ASSEMBLE

THE

KIT

Select one air helper spring from your kit. Install the upper bracket

by aligning the three holes on the air spring with the holes on the upper

bracket. Fasten the upper bracket to the air spring using the 3/8" x 3/4"

hex bolts as shown in Figure “A”. Install the air fitting as shown in

Figure “A”. Tighten the air fitting to make contact with the Teflon ring

and then tighten an additional 1/2 turn. No thread sealant is needed.

Insert the bail clamp into the lower bracket. Next, attach the lower

bracket and disk to the air spring using the 3/8"x 3/4" hex bolt (see

Figure “A”). Note: Finger tighten the bolt securing the lower bracket

and disk allowing the air spring to move freely. This will be tightened

after alignment in Step 6.

S

TEP

3 - A

TTACH

LOWER

BRACKET

TO

LEAF

SPRING

Place the assembly on the left side on top of the leaf spring stack

forward of the axle (see Figure “A” and “B”). Note the slight difference

in the lower bracket position on top of the leaf spring plate between Ford

and GM. Attach the lower bracket to the leaf stack using the bail clamp

(installed earlier), the bracket strap, and the flange lock nuts as shown

in Figure “A” and “B”. (Tighten to 15-20 ft. lbs.)

S

TEP

4- (GM TRUCKS)

Remove the jounce bumpers located under the frame rail by removing

the bolt located inside the bumper. The hardware will not be re-used with

this kit. Insert a M10 x 40MM bolt and lock washer through the bottom

of the jounce bumper and into the small hole in the top. Place the spacer

over the bolt. Insert the bolt into the existing hole in the frame and secure

with a M10 nut. See Figure “F”.

CAUTION: The frame rails on some GM trucks have reinforcing ribs

used to strengthen to the frame rail. DO NOT drill through these ribs. If

the holes in the upper bracket align with these ribs, choose another hole

which is not on the rib and let the upper bracket rest against the rib. You

must use 2 holes on each side of the upper bracket. GM trucks with the

reinforcing ribs will require a flat washer between the upper bracket and

the frame to allow the upper bracket to rest squarely against the rib.

AIR HOSE

INFLATION

VALVES

BUMPER

AIR

SPRINGS

Figure "D"

Figure "C"

Figure "E"