2 screw-in tools for seats, 3 tightening torques, Name plate, ce and body markings – Richter RSS/F Series Bellows-Sealed Control Valves User Manual

Page 4: Screw-in tools for seats, Tightening torques, Series rss/f, 1 name plate, ce and body markings

Series RSS/F

Page 4

9260-060-en

Revision 03

TM 7168

Edition 06/2008

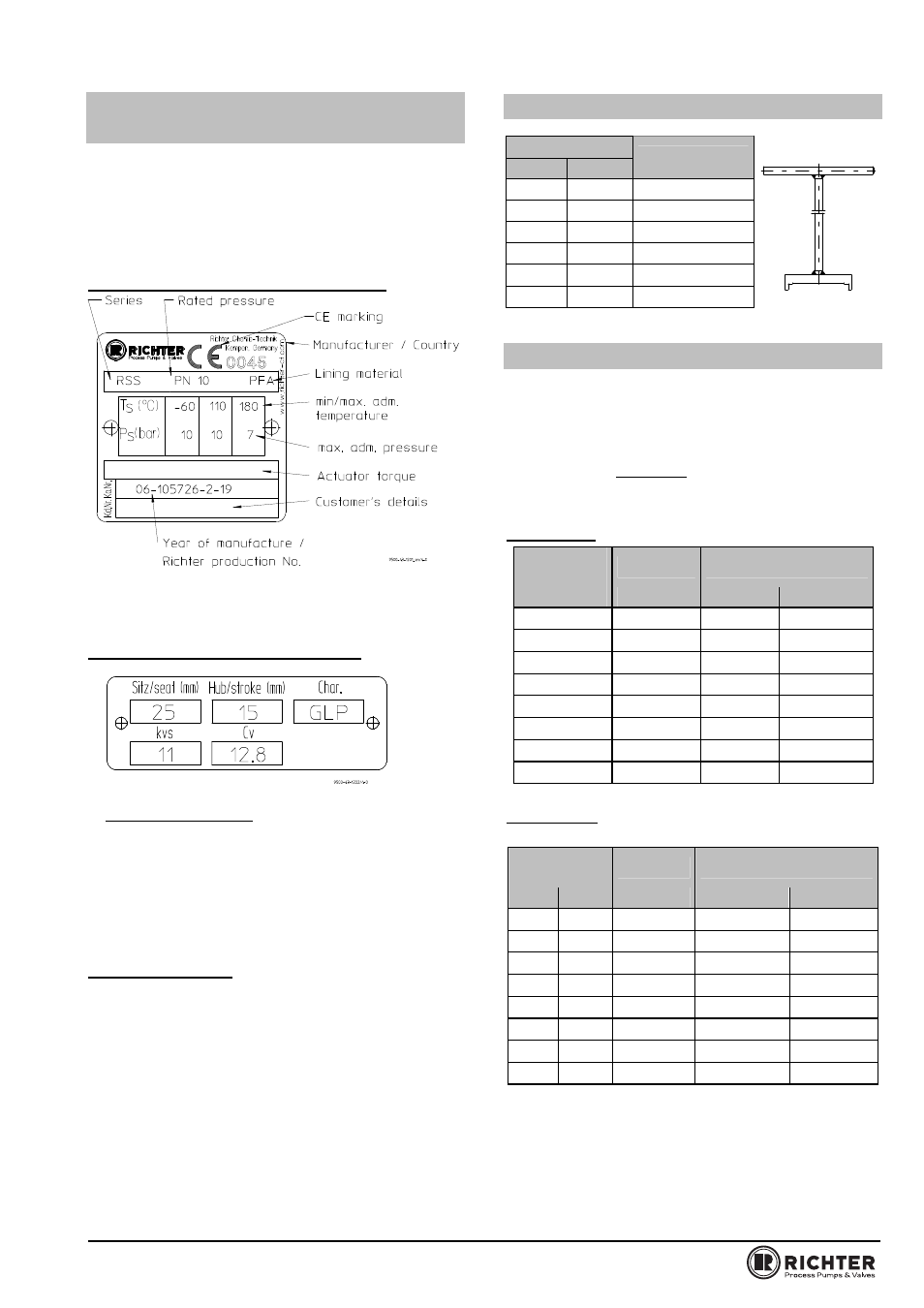

1.1 Name plate, CE and body

markings

The stainless steel name plate is undetachably riveted

to the body.

If the operator attaches his identification, it must be

ensured that the valve matches the application in

question.

Example of name plate with CE marking:

No CE marking is permissible for the sizes 15, 20 and

25; the name plate therefore has no CE marking.

Example: Name plate for control data

If heavy-duty bellows are installed, another name

plate indicates this:

HD - BVA = Heavy-duty bellows with support rings

of stainless steel

HD - BKo = Heavy-duty bellows with support rings

of PTFE/carbon

Body identification:

The following are visible on the body according to DIN

EN 19 and AD 2000 A4:

Nominal size

Rated pressure

Body material

Manufacturer's identification

Melt number/Foundry identification

Cast date

Arrow for direction of flow

1.2 Screw-in tools for seats

Nom. size

[mm]

[inch]

Article No.

15, 20 ½“, ¾“

9568-96-1011

25 1“

9568-96-1001

40 1½“

9568-96-1002

50, 65

2“

9568-96-1003

80 3“

9568-96-1004

100 4“ 9568-96-1005

1.3 Tightening

torques

All screws greased, tighten in diametrically

opposite sequence!

The tightening torques for pipe screws and body

screws mentioned must not be exceeded. For an

exception, see Section 8, Flange connection valve /

pipe is leaking.

The following tightening torques are recommended.

Pipe screws, flanges to ISO/DIN

Flange

nom. size

Screws

Tightening torque

[mm]

[ISO/DIN]

[Nm]

[in-lbs]

15

4 x M12

6

55

20

4 x M12

8

70

25

4 x M12

10

90

40

4 x M16

20

175

50

4 x M16

26

230

65

4 x M16

40

355

80

8 x M16

25

220

100

8 x M16

35

310

Pipe screws, flanges to ASME Class 150 or flanges

ISO/DIN drilled to ASME Class 150

Flange nom.

size

Screws

Tightening torque

[mm]

[inch]

[ASME]

[Nm]

[in-lbs]

15

½

4 x ½“

5

45

20

¾

4 x ½“

6

55

25

1

4 x ½“

8

70

40 1½ 4

x

M“

15 135

50 2 4

x

M“

25 220

65 -- 4

x

M“

30 265

80 3 4

x

M“

45 400

100 4 8

x

M“

35 310