2 assembly, 3 replacing seat, Assembly 15 – Richter RSS/F Series Bellows-Sealed Control Valves User Manual

Page 15: Replacing seat, Series rss/f

Series RSS/F

Page 15

9260-060-en

Revision 03

TM 7168

Edition 06/2008

9.2.2 Assembly

DN 15 - DN 65 (½“.– 2½“)

Insert guide rings 302/1, 302/2.

Clamp valve stem 800 in a vice with protective

jaws.

Screw bellows 206 without lubricant onto the valve

stem 800 and tighten by hand.

Check to see whether the new plug 204 fits in the

valve seat 205. Make sure that neither the seat

nor the plug is damaged.

Screw plug 204 with plug onto the bellows 206

without lubricant and tighten by hand.

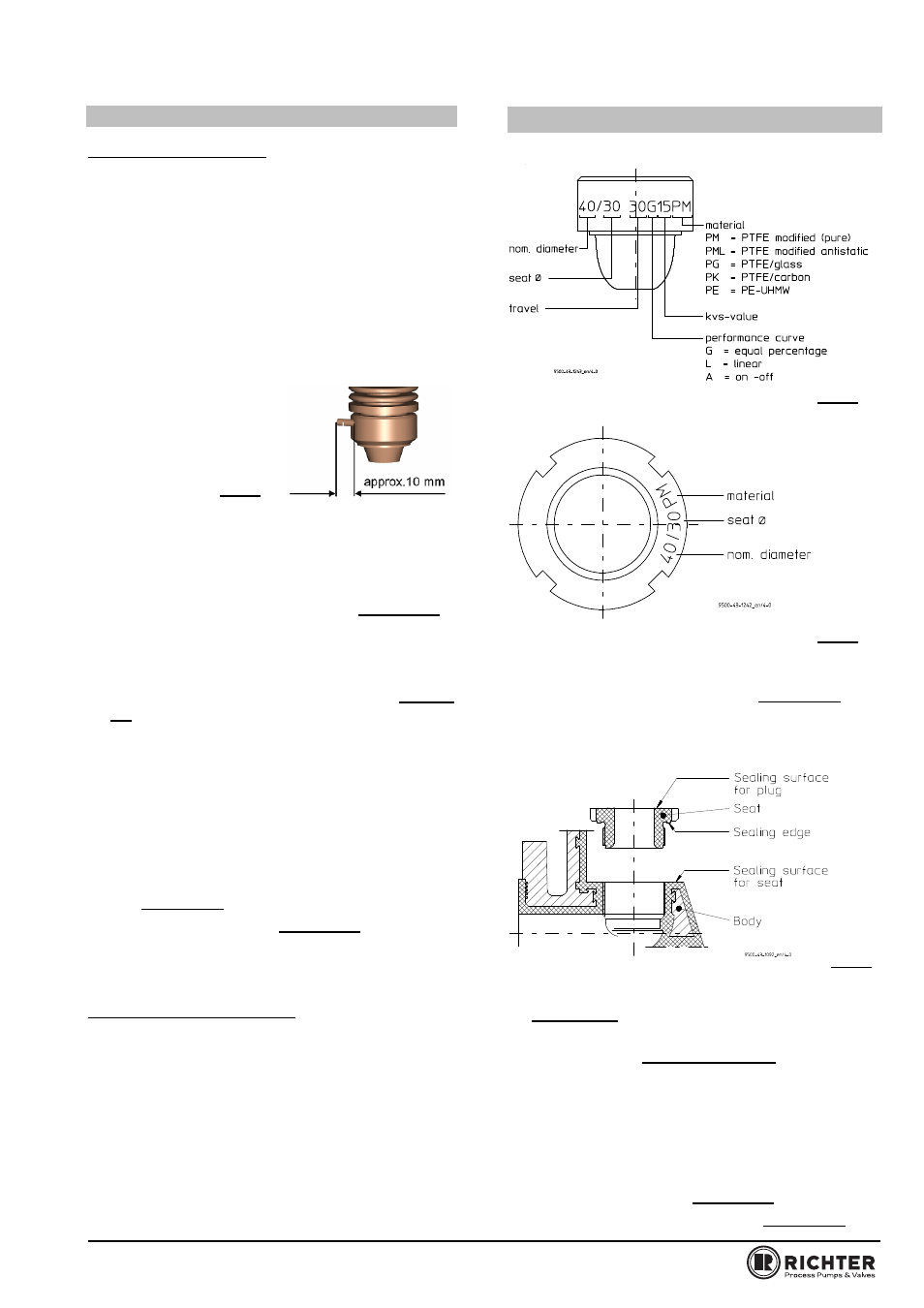

Press round cord 522

into the plug 204

leaving about 10 mm

over. This facilitates

the next dismantling

operation.

Fig. 2

Install valve stem 800 with bellows 206 and plug

204 without lubricant into the cover 106.

Insert packing rings 402/1 offset by 90° and thrust

ring 405 into the cover and tighten with packing

nut 404. For tightening torques, see Section 1.3.

Screw travel stop 508 and lock nut 920/2 onto the

valve stem 800.

Carefully lower upper section into the body.

Install cover 106. Tightening torques see Section

1.3.

If the bracket 510 or yoke 516 was dismantled,

install it again. Tighten groove nut 509/1.

Mount the protective bellows 687 with inserted

snap rings 954/1 onto the valve stem 800.

Mount clip 937/1 onto the valve stem 800.

If the actuator 850 was removed, mount it again

now.

Set valve and mount coupling 804.

See Section 9.4.

Set travel stop 508. See Section 9.1.

Attach protective bellows 687 with clip 937/1.

Connect monitoring connection again.

DN 80 und DN 100 (3“ und 4“)

Press guide 801 into the cover 106 without

lubricant.

Now continue as described under assembly

DN 15 - DN 65 (½“.– 2½“).

9.3 Replacing

seat

The seat is marked with:

Fig. 3

The plug is marked with:

Fig. 4

A screw-in tool is required for assembling and

dismantling the seat 205. The article numbers for the

individual nominal sizes are listed in Section 1.2.

The new seat is to be carefully protected prior to

assembly. The sealing edge and the sealing surface

for the plug must not be damaged.

Fig. 5

Remove the upper section as described in

Section 9.2.

Using the Richter screw-in tool, turn the seat 205

out of the body. Right-hand thread.

Carefully clean the sealing surface in the body 100

and check for

If there is any damage, you can try to rework the

sealing surface.

Screw the new seat 205 into the body 100 without

lubricant using the Richter screw-in tool. For

tightening torques, see Section 1.3.

Further assembly as described in Section 9.2.