8 assembly, 1 assembly of housing / shaft spider, 2 assembly of slide-in unit – Richter RMI-B Series User Manual

Page 19: 3 assembly of drive unit, Assembly, Assembly of housing / shaft spider, Assembly of slide-in unit, Assembly of drive unit, Series rmi-b

Series RMI-B

close-coupled design

Page 19

9470-055-en

Revision 02

TM 8256

Edition 06/2011

7.8 Assembly

A complete assembly process is described in the

following.

Sub-sections can be deduced from this.

7.8.1 Assembly of housing / shaft spider

Push or press the shaft spider 338 into the housing

100 together with the two anti-torsion inserts

566/1.

Use a suitable plastic tube for pressing.

The pressing force must only be

applied over the sliding surface of the

shaft spider.

(risk of the silicon carbide breaking)

Insert shaft sleeve 523/1 into the shaft spider 338.

7.8.2 Assembly of slide-in unit

Press the inner magnet assembly 859 onto the

impeller 230. Pay attention to the correct alignment

of the driver cams.

Press the circlip 932/7 into the appropriate groove

on the impeller 230 with a suitable plastic tube.

Make sure that the click connection of the circlip

932/7 audibly engages to perform its function.

Press the bearing bush 545/1 into the impeller 230

together with the anti-torsion insert 566/2.

Make sure that the anti-torsion insert 566/2 is

approx. 2 mm shorter than the plain bearing.

Insert the distance ring 504/1 and then the bearing

bush 545/2.

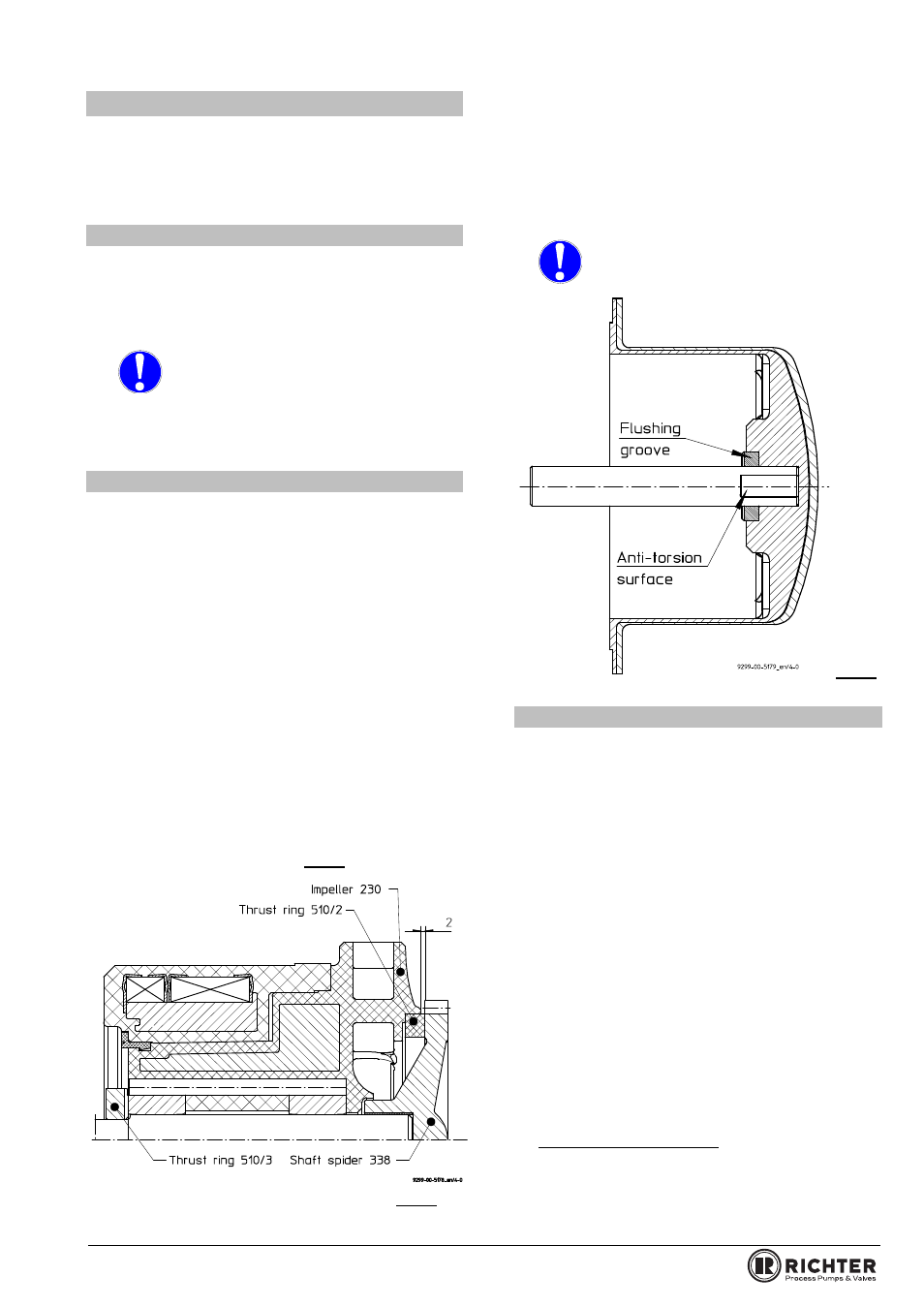

Carefully press the thrust ring 510/2 into the

impeller 230 right to the stop. Pay attention to the

correct position of the anti-torsion insert grooves in

relation to the carrier webs in the impeller 230.

Check whether the thrust ring protrudes about 2

mm out of the impeller. See Fig. 8.

Fig. 8

Assemble can 159 and can insert 158. To

simplify assembly, the can insert 159 can be

cooled if necessary.

Introduce thrust ring 510/3 into the can insert

158. Make sure that the flushing grooves are

facing outwards.

Press shaft 222 into the can insert 158.

CAUTION: Align the shaft with the flat

pivot point in the thrust ring (risk of

the silicon carbide breaking)

Fig. 9

7.8.3 Assembly of drive unit

Affix adapter 346 to the motor flange with hex.

screws 901/7.

Check fit of the drive magnet assembly

858/hollow drive shaft 216.

Using Anti-Seize special assembly paste (e.g.

from Weicon) assemble the shaft 216 to the outer

magnet 858.

Tighten hex. socket screw 914/5 with toothed

lock washer 936/1.

Put 1 drop of adhesive on the thread of the drive

shaft, e.g. Loctite 243 from the company Loctite

(Dublin, Munich or Vienna) or an equivalent.

Only one drop of the adhesive is to be applied

per thread. Otherwise the next dismantling

operation will be more difficult or no longer

possible without destroying components.

Tightening torque group 1.1 + 1.2 = 17Nm

Tightening torque group 1.3

= 20Nm

Assemble the hollow drive shaft 216 / drive

magnet assembly 858 unit to the motor shaft.

Motors acc. IEC-standard:

After setting the “F” dimension, use a 1/4” drill bit

to drill 1 hole 1/16” deep where the set screw

contact the key. This will ensure there is no

movement of the outer drive during operation.