1 intended use, 2 tightening torques, Intended use – Richter MNKA-B Series (ASME) User Manual

Page 4: Tightening torques, Casing) markings, Series mnka-b, Installation and operating manual, Acc. to asme/ansi

Installation and Operating Manual

Series MNKA-B,

acc. to ASME/ANSI

9250-055-en

Revision 01

TM 5976 MPE/Wm

Page 4

Edition 10/2004

Sizes :

Group 1

Group 2

1.5“ x 1“ x 6“

3“ x 1.5“ x 8“

3“ x 2“ x 6“

2“ x 1“ x 10“

1.5“ x 1“ x 8“

1.1 Intended use

ITT Richter pumps of the series MNKA-B (ASME) are

sealless, plastic-lined magnetic drive centrifugal

pumps for the leak-free conveyance of aggressive,

toxic, pure and inflammable liquids.

The pump is equipped with a permanent magnetic

synchronous drive.

For vertical installation of the pumps, please consult

the manufacturer.

The observance of the specified physical

limits is important for perfect functioning and

safe operation, especially with regard to

explosion protection to prevent potential sources of

ignition (see Section 2.5):

It must be ensured that the pump is always filled

with liquid during operation.

For safe pump operation, we recommend a flow

rate which lies between 0.3 and 1.1 Q

opt

. The

maximum operating temperature must never be

exceeded. See Section 2.5.7. In case of doubt,

you must consult the manufacturer.

The manufacturer must be consulted in the event

of entrainment of gas >2% as well as solids in

order to avoid a lack of lubrication and dry-running.

The plant NPSH value (NPSHA) should be 0.5 m

higher than the NPSH value of the pump

(NPSHR). See also Section 5.4.1..

Inadmissible modes of operation, even for a

short period, may result in serious damage to

the unit.

In connection with explosion protection, potential

sources of ignition (overheating, electrostatic and

induced charges, mechanical and electric sparks) may

result from these inadmissible modes of operation;

their occurrence can only be prevented by adhering to

the intended use.

Furthermore, reference is made in this connection to

the European Directive 95/C332/06 (ATEX

118a)

which contains the minimum regulations for improving

the occupational health and safety of the workers who

may be at risk from an explosive atmosphere.

This unit must not be operated above the

values specified in the data sheet as regards

the fluid to be conveyed, flow rate, speed,

density, delivery head and operating temperature as

well as the motor rating.

The instructions contained in the operating

manual or contract documentation must be

observed; if necessary consult the manufacturer.

All important features are documented in the data

sheet included in the scope of delivery.

In the event of operating conditions other than those

described in the data sheet, the following are to be

checked again:

design of the pump

design of the accessories

suitability of the materials.

1.2 Tightening

torques

Screws greased, tighten in diametrically opposite

sequence

Housing screws 901/3

Size

[inch]

No. x size

ASME

Nm

in-lbs

1.5“ x 1“ x 6“

8 x ½“

35

310

3“ x 2“ x 6“

8 x ½“

35

310

1.5“ x 1“ x 8“

10 x ½“

35

310

3“ x 1.5“ x 8“

12 x ½“

30

265

2“ x 1“ x 10“

12 x

5/8

“

45 400

Pipe screws, flanges to ASME

DN

[inch]

No. x size

ASME

Nm

in-lbs

1“

4 x ½“

12

105

1½“

4 x ½“

20

135

2“

4 x

5/8

“

35

220

3“

4 x

5/8

“

40

355

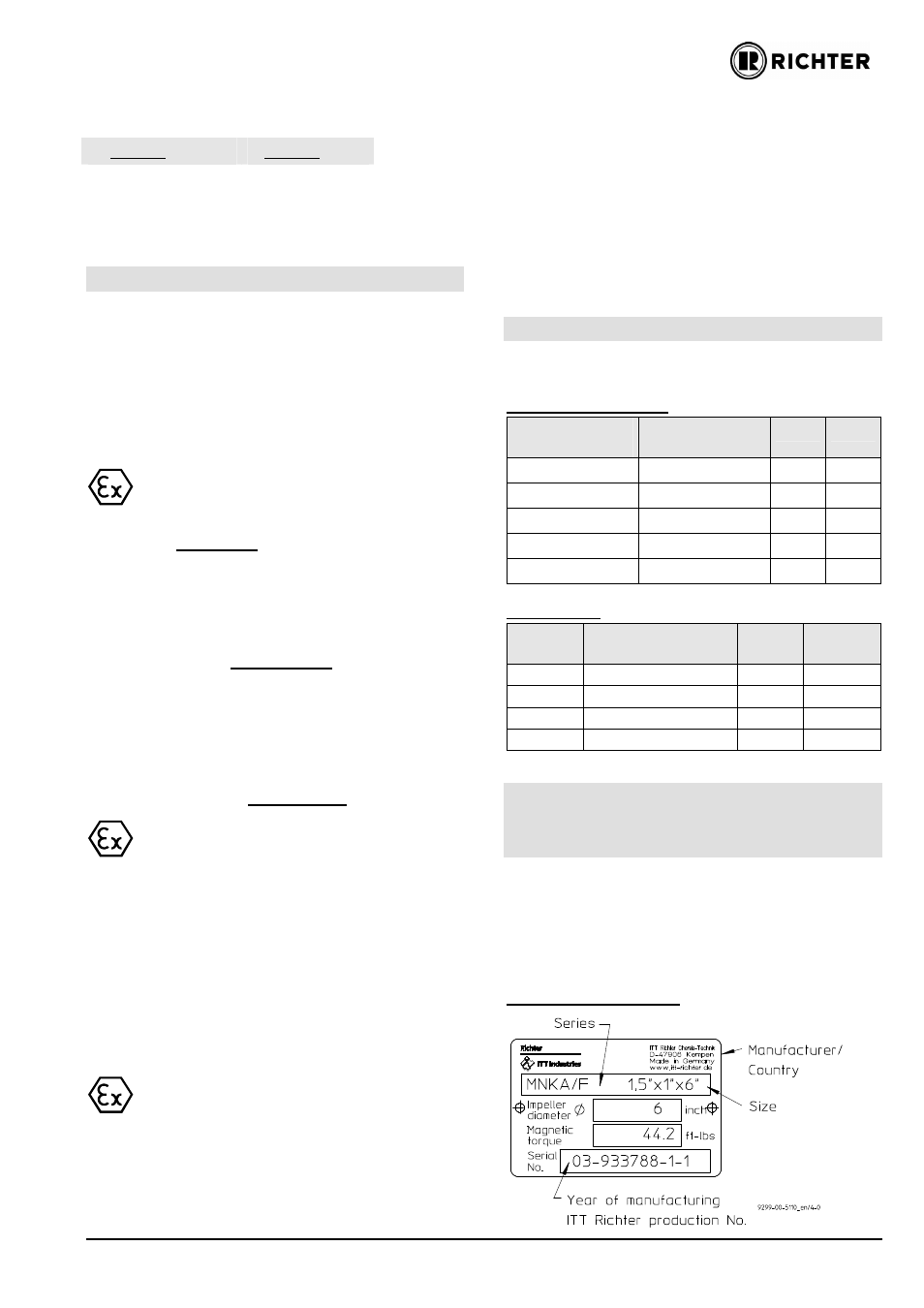

1.3 Name plate, dry-running, CE

and housing (casing)

markings

The stainless steel name plate is firmly riveted to the

housing (casing):

If the operator attaches his identification, it must be

ensured that the pump matches the application in

question.

Example of name plate: