4 piping, 1 nominal size, 2 nozzle loads – Richter MNKA-B Series (ASME) User Manual

Page 10: 3 suction line, 4 supply lines, 5 discharge line, 6 venting and draining, Piping, Nominal size, Nozzle loads

Installation and Operating Manual

Series MNKA-B,

acc. to ASME/ANSI

9250-055-en

Revision 01

TM 5976 MPE/Wm

Page 10

Edition 10/2004

5.4 Piping

Before the pump is installed, both the suction and

supply lines as well as the discharge line are to be

cleaned.

Dirt or damage to the sealing surfaces is best avoided

if the flange covers remain on the flanges until just

before installation.

Use flange gaskets suitable for the medium.

The screw tightening torques in Section 1.2 are to be

observed for tightening the flange screws.

5.4.1 Nominal size

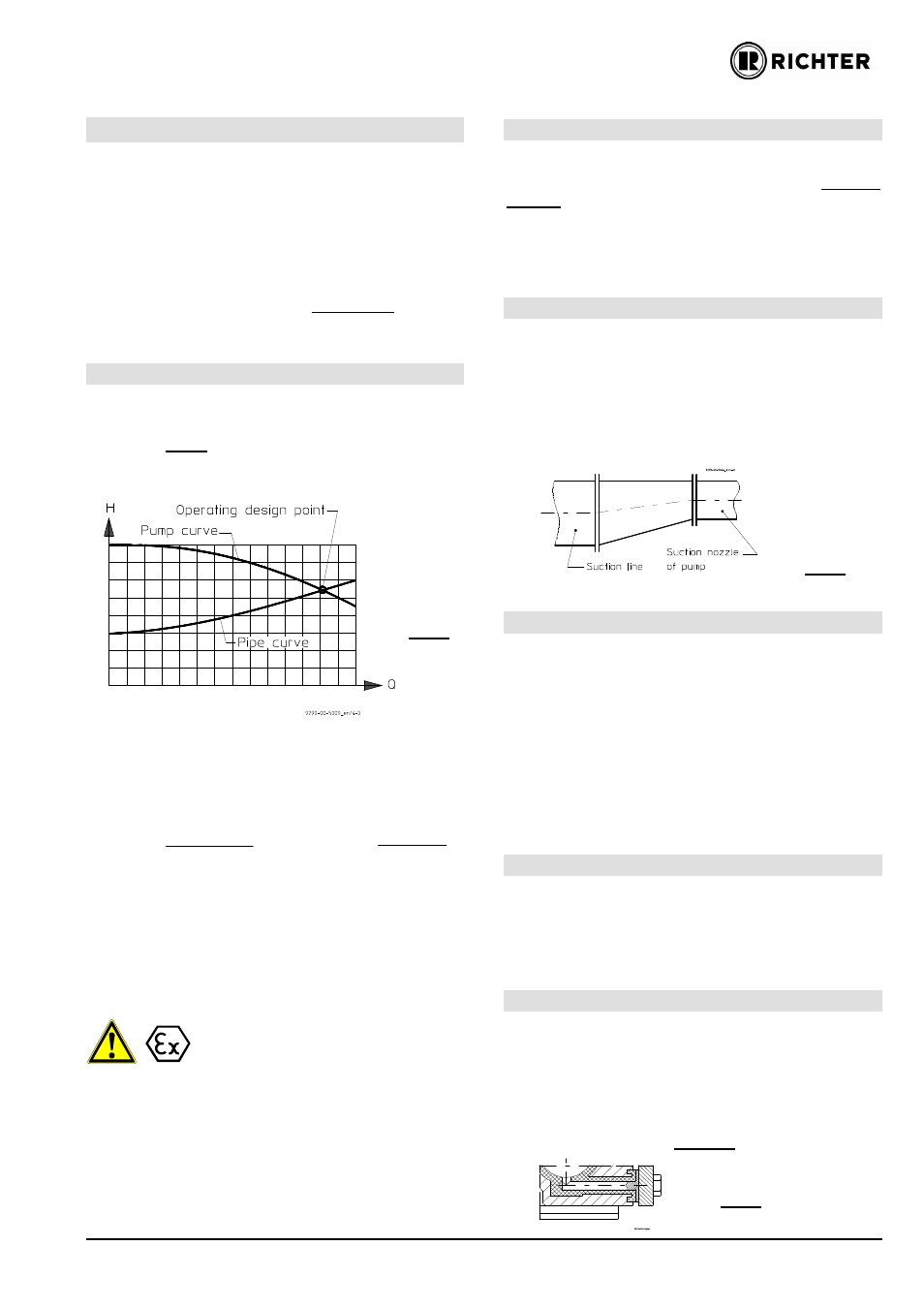

The operating design point of a centrifugal pump lies

at the intersection of the pump curve and the pipe

curve, see Fig. 2. The pump curve is provided by the

pump manufacturer. The pipe curve is determined

using diagrams or PC programs.

Under no circumstances can the nominal size of the

piping be derived from the connected nominal size of

the pump.

The pipe nominal size can also be determined using

the flow rate as a rough guide.

)

ft

(

A

x

449

)

gpm

(

Q

)

s

/

ft

(

v

2

=

)

m

(

A

)

s

/

m

(

Q

)

s

/

m

(

v

2

3

=

The velocity in the suction line should not exceed

6.56 ft/s (2 m/s) and 16.4 ft/s (5 m/s) in the discharge

line.

When determining the suction line nominal size, the

NPSH value (net positive suction head) must also be

observed. The

NPSHR value

required for the pump is

specified in the data sheet.

The NPSHR available in the plant

should be at least 1.64 ft (0,5 m)

higher than the NPSHR required for

the pump. Otherwise, this will lead to a drop in the

delivery head, cavitation or even failure of the pump.

5.4.2 Nozzle loads

The pump can be subjected to nozzle loads in

accordance with ISO

5199. See also

Product

manual

.

Changes in the length of the piping caused by

temperature are to be allowed for by appropriate

measures, e.g. the installation of expansion joints.

5.4.3 Suction line

The suction lines must always be laid on a rising

gradient towards the pump. Otherwise, gas bubbles

may form which considerably reduce the suction line

cross section. Eccentric transition elements must be

installed between different pipe diameters.

Valves which disrupt the course of flow should not be

installed directly upstream of the pump.

Fig. 3

5.4.4 Supply lines

Supply lines should vent towards the reservoir and are

therefore to be laid with a constant downward gradient

towards the pump. Should the piping internals

upstream of the pump be horizontal, a low point can,

of course, be located upstream of these internals.

From here the pipe is then laid with an upward

gradient to the pump so that the gas bubbles which

form here can escape through the pump.

Valves which disrupt the course of flow should not be

installed directly upstream of the pump.

5.4.5 Discharge line

Do not arrange the shut-off valve directly above the

pump but initially provide a transition section.

The discharge nozzle velocity of the medium can – if

necessary – be reduced.

5.4.6 Venting and draining

Venting can take place into the discharge line or

upstream of the discharge valve.

A venting line can also be used as a bypass, drain or

flushing line.

The pump housing (casing) is fitted with a drain

connection as a standard feature. Optionally, the drain

bore can be drilled. See

Figure 4

.

Fig. 2

Fig. 4