5 maintenance, 1 external, single mechanical seal, 1 dismantling – Richter RSI Series User Manual

Page 5: 2 notes on assembly, External, single mechanical seal, Dismantling, Notes on assembly, 5maintenance, Series rsa

Series RSA

,

Mechanical Seals, external, single or

Page 5

double, type Crane 58U – 58U

9485-060-en

Revision 11

TM 8046

Edition 10/2010

5

Maintenance

The regulations of the mechanical seal

manufacturer must always be observed.

See also the installation and operating manual

for the RSA or RSI series.

5.1 External, single mechanical

seal

In normal operations this seal should not drip. The

leak should only be so minimal that it evaporates

immediately.

It is advisable to check the attachment screws of the

mating ring adapter 487 and of the rotating unit 470/2

for a tight fit from time to time.

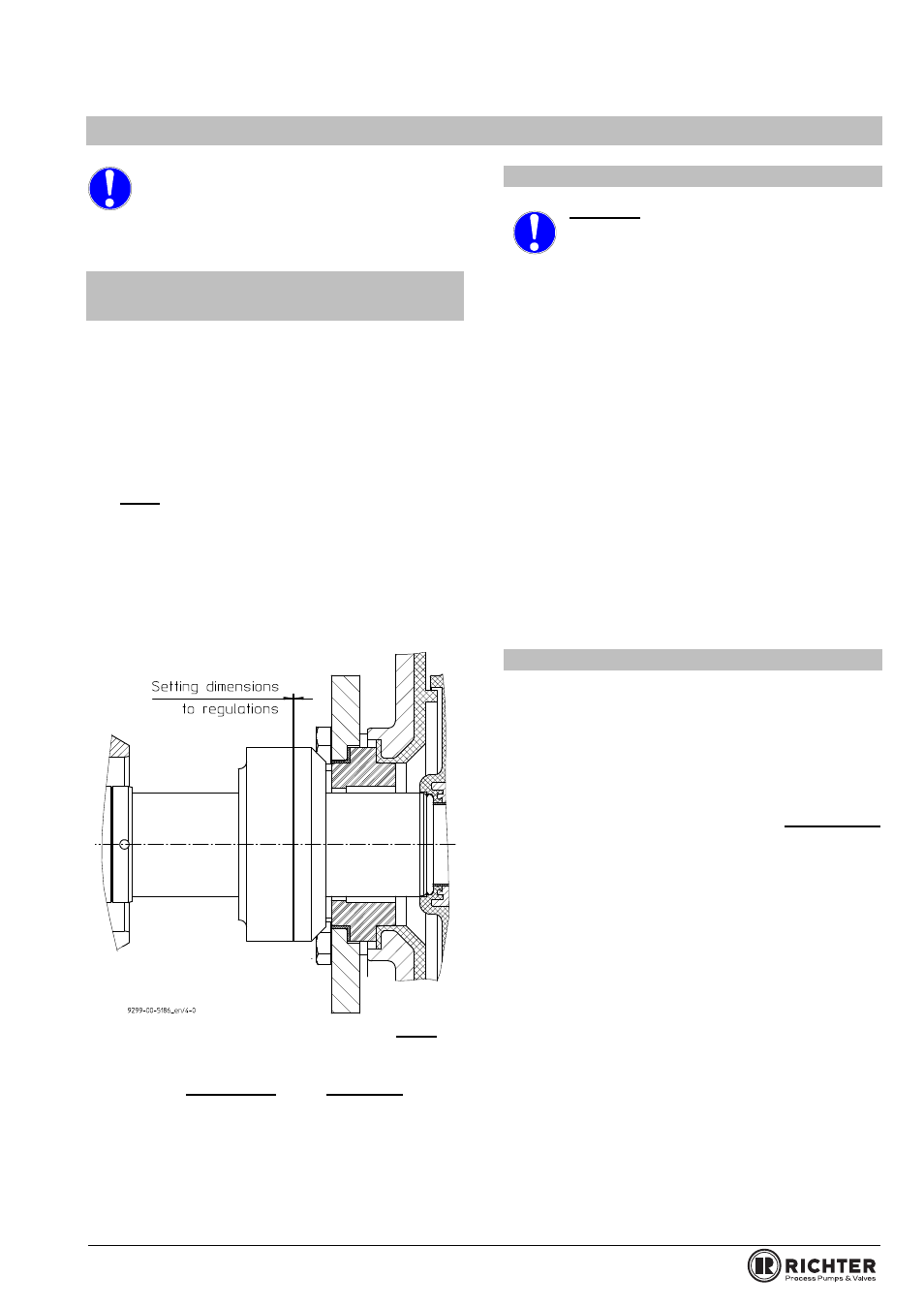

The wear on the rotary ring can be readily seen by the

increased size of the set dimension in many makes.

See Fig. 1.

The external mechanical seals are to be replaced

before the wear on the rotary ring become so great

that the pressing forces are no longer sufficient

as a result major leaks occur.

Often marks on the mechanical seal indicate the

admissible wear.

Fig. 1

Dismantling can be checked using the sectional

drawings in Section 7.3 and Section 9 of the

installation and operating manual RSA or RSI as well

as the components available.

.

5.1.1 Dismantling

CAUTION: Make sure that the protective

shaft sleeve 524 remains on the shaft 210

and does not fall down (risk of breakage)

Deposit bracket 344 with the plastic side facing

downwards on a soft surface.

Pull the protective shaft sleeve 524 with the

rotating unit 470/1 off the shaft 210. The

replaceable shaft sleeves 523/2 and 523/3 are

normally removed as well.

Remove the seal guard 685 on one or both sides,

depending on requirements, by undoing the hex.

socket screws 914/1.

Undo the clamp connection of the single

mechanical seal and pull the rotating unit off the

protective shaft sleeve 524.

Undo hex. screws 901/4 and remove mating ring

adapter 487 with intermediate ring 509/1.

Push mating ring 475/1 out of the bracket.

When changing the rotating unit 470/1, observe

the operating manual of the mechanical seal

manufacturer.

5.1.2 Notes on assembly

Only use original spare parts.

Do not use any defective parts.

The recommendations of the mechanical seal

manufacturer are to be observed.

External single mechanical seals can be best set

to the required pre-tension with a clamping device

which is available from Richter. See Section 10.4.

Assembly aids, in the Installation and Operating

Manual RSA or RSI.

Prepare rotating unit (observe setting dimension,

see fig. 1) and tighten on the protective shaft

sleeve.