6 monitoring facilities, 7 drive, 8 electric connection – Richter MNK-B Series User Manual

Page 12: Monitoring facilities, Drive, Electric connection, Series mnk-b

Series MNK-B,

close-coupled design

Page 12

9230-055-en

Revision 09

TM 7345

Edition 10/2008

Fig. 5

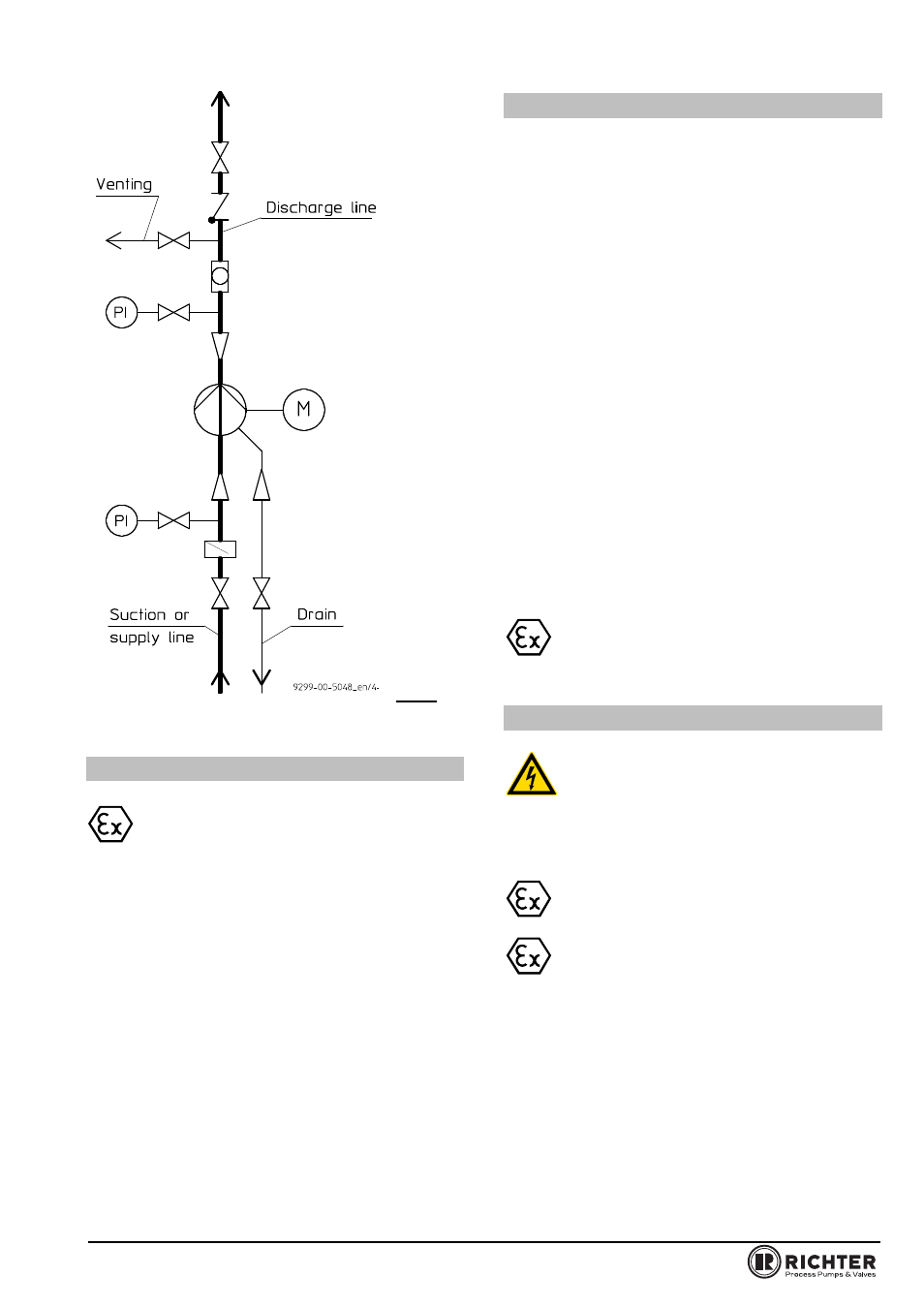

5.6 Monitoring facilities

Appropriate monitoring facilities are to be

recommended,

depending

on

the

requirements placed on operational safety and

availability of the unit.

Richter provides information on request and can

supply:

Flow meters

Filling level indicators

Motor load monitors

Temperature monitors

Can monitors

Leak monitors

CMS "Condition Monitoring System"

You can obtain the publications "Safe Operation of

Magnetic Drive Pumps" and "The Operation of

Centrifugal Pumps without NPSH Problems" on

request.

5.7 Drive

The power consumption of the pump at the operating

design point is specified in the data sheet and works

certificate. If the operating design point was not known

when the pump was dispatched, the power

consumption can be read off the appropriate

performance curves. The max. density, the max.

viscosity and a safety margin are to be allowed for.

Care must be taken when selecting the motor size to

ensure that the excess power is not too great. During

start-up the magnetic drive could otherwise stop.

The magnetic drive rating at the nominal speed of

2900 rpm is given in the pump data sheet.

If the motor rating exceeds this magnetic drive rating –

at nominal speed -, it is necessary to check for any

stoppage of the magnetic drive.

This also applies if the required drive rating exceeds

80% of the magnetic drive rating – at nominal speed.

Consult Richter if necessary.

Different operating data can be achieved without

changing the pump through the use of different

speeds, e.g. by means of a frequency converter.

The pump with base plate and motor is illustrated in

the installation drawing.

The operating manual of the motor manufacturer

must be observed.

A motor with a valid ATEX certificate is to be

used if employed in zone 1 and 2.

5.8 Electric connection

Only have the electric connection performed

by a qualified electrician. Compare the

available mains voltage with the information

on the type plate of the motor and select a suitable

circuit.

It is urgently recommended to use motor protection

facilities (motor protection switch).

In potentially explosive areas IEC 60079-14

must also be observed for the electrical

installation.

It must be ensured that the pump is grounded

at the housing 100.

This can be achieved in the simplest case by

using of tooth-lock washers or contact discs if the

substructure itself is grounded.

Otherwise, grounding must be ensured by other

means, e.g. cable bridges.

Units supplied by Richter (pump and base plates) are

to be grounded using suitable devices on the base

plate.