Kenco Engineering KLCP User Manual

Page 2

II. INSTALLATION AND MAINTENANCE INSTRUCTIONS FOR OIL INLET VALVE:

•

Connect the oil supply line to the oil inlet on the oil level controller. The minimum recommended supply line is ¾” I.D. The

supply line must be clean and it is recommended that it be flushed with solvent before installation.

•

Connect the oil supply line to the oil supply tank. If there is no existing valve at the tank or the existing supply outlet, a shut-off

valve should be placed in the line to prevent oil loss when cleaning the inlet screen or filter.

•

For high pressure models HP-A, pressure range must be between 5 psi and 34 psi. For high pressure units HP-B, pressure

range must be between 35 psi and 70 psi.

•

The oil inlet valve is adjusted to maintain the oil level at the center of the sight glass. Low or high levels are often caused by

two problems:

1. Excessive oil inlet pressure, which will cause the unit to overfill.

2. Improper equalizing lines between the crankcase and the controller will also result in improper levels.

Note: Low pressure models require a minimum of 2’ of head pressure and a maximum of 15’ of oil inlet head pressure.

III. INSTALLATION INSTRUCTIONS FOR UNITS WITH ADAPTERS:

OIL LEVEL CONTROLLERS WITH

–9

(Universal adapter),

-

10

(Slotted universal adapter),

-12

(Pole mounted adapter) AND –

FS OPTIONS

•

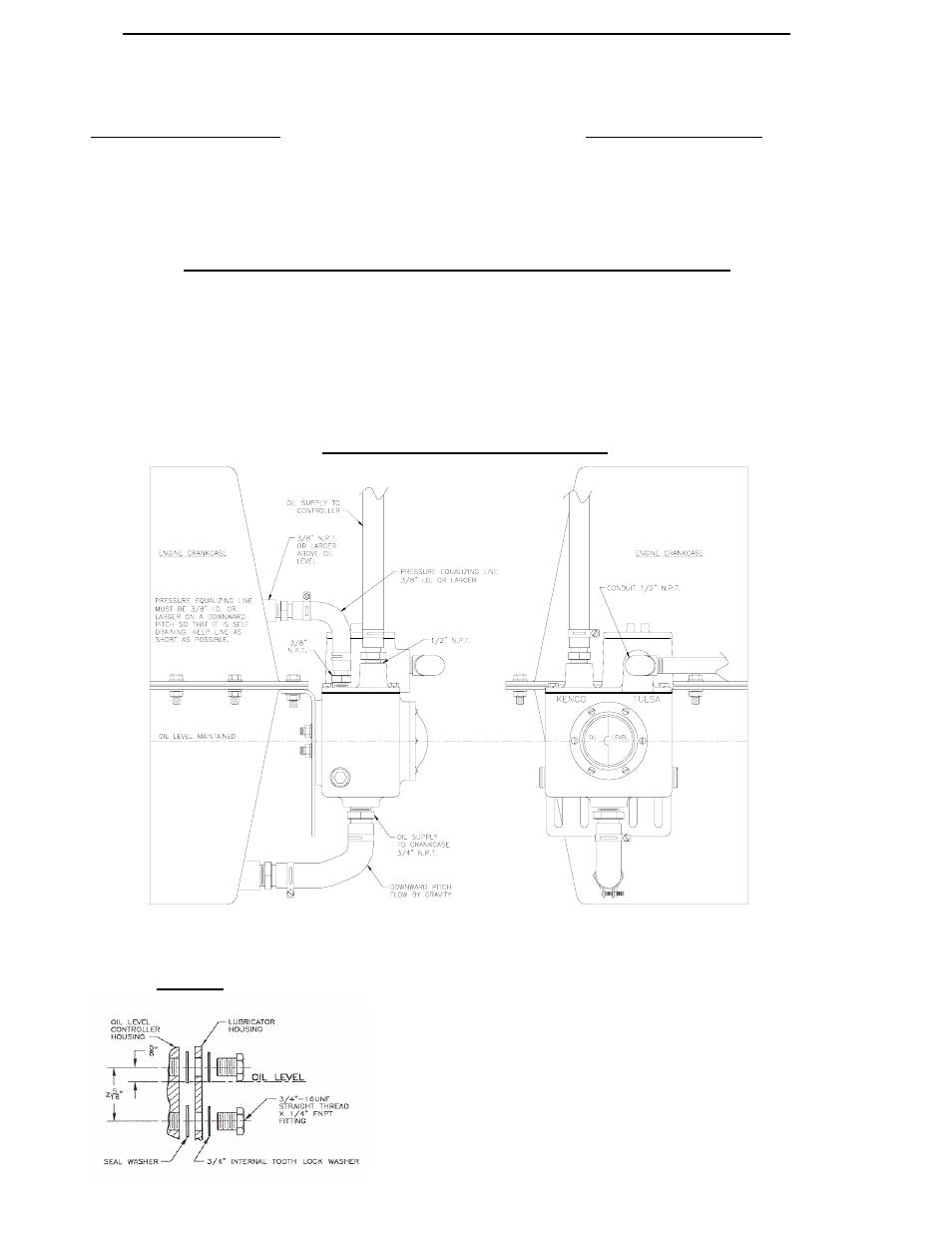

Set the controller so that the centerline of the sight window corresponds to the desired oil level in the crankcase.

•

Mount the controller close to the crankcase and connect the hose from the ¾” outlet located on the controller to the crankcase.

NOTE: The outlet port on the oil level controller must be located below the oil level in the crankcase.

•

An equalizing line must be used between the controller and crankcase in order to equalize the pressure. The tubing must be a

minimum of 1/2” I.D. and must be kept under 2 feet. DO NOT loop this line. It must be trap free and self draining, with a

downward pitch flow by gravity.

OIL LEVEL CONTROLLER WITH

–11

AND

–11-FS

OPTION (for Mechanical Lubricators): See Figure 3

• Drill holes in the lubricator housing as shown, and mount

the controller with the inlet located on the top side using the

seal washers and mounting bolts provided.

• Place the seal washers between the controller and the

lubricator housing.

Figure 3

Figure 2: Typical Mount of –9 Adapter