Watts WPTS24-5W User Manual

Waterpex, Field repairs, Crimpring

WARNING: Use this Field Repair Guideline only for the repair of

WaterPEX

®

damaged in the field. Read complete instructions

before beginning repairs. Do not splice together multiple lengths of

tubing. See installation manual for recommended circuit lengths.

Purchase repair components individually, or purchase the Watts cou-

pling kit that contains all the necessary parts.

CAUTION: Use of materials not supplied by Watts to make a splice or

manifold connection may eventually result in leaks. Watts WaterPEX

®

and fittings are engineered to work together. Watts extends no warranty

— expressed or implied — to any failure or damage of any kind result-

ing from use of materials not supplied by Watts (see WaterPEX

®

war-

ranty for specifics).

1. Cut the PEX tubing. Make a straight cut-off on both pieces of

PEX to be spliced together, 90° to the pipe.

2. Select the Correct Brass Coupling and Fitting. Use only Watts

brass couplings and fittings to repair WaterPEX

®

.

NOTE: Our research shows that Watts fittings make the best

connections for WaterPEX

®

. Off-the-shelf brass fittings might be

made to different dimensions and tolerances — do not use them.

Field repairs are not covered by any warranty either expressed or

implied. See WaterPEX

®

warranty statements.

3. Choose the Correct Fittings. Make sure you select the correct fit-

tings to make the connection.

4. Make the Connection. See photos at right and follow the steps

carefully. Where necessary, see Watts manual and/or tool-usage

guidelines. Pressure test all connections to 50psi minimum.

NOTE: When making a buried slab repair, protect the final splice

assembly with a double wrap of PVC electrican’s tape or shrink wrap.

If there is room, wrap the connection with 6"–8" of polyethylene pipe

insulation; then wrap with electrician’s tape.

CAUTIONS:

a. Do not solder near, or overheat, any PEX connection. Extreme

temperatures associated with soldering may seriously damage the

PEX and will void any warranty.

b. All PEX and brass branch surfaces must be clean and dry before

making the connection.

c. Whenever possible, avoid making splices in inaccessible locations.

d. Repairing PEX that has been in service may require special

attention. Make sure the interior of the tubing is free of debris before

completing the connection.

WaterPEX

®

Field Repairs

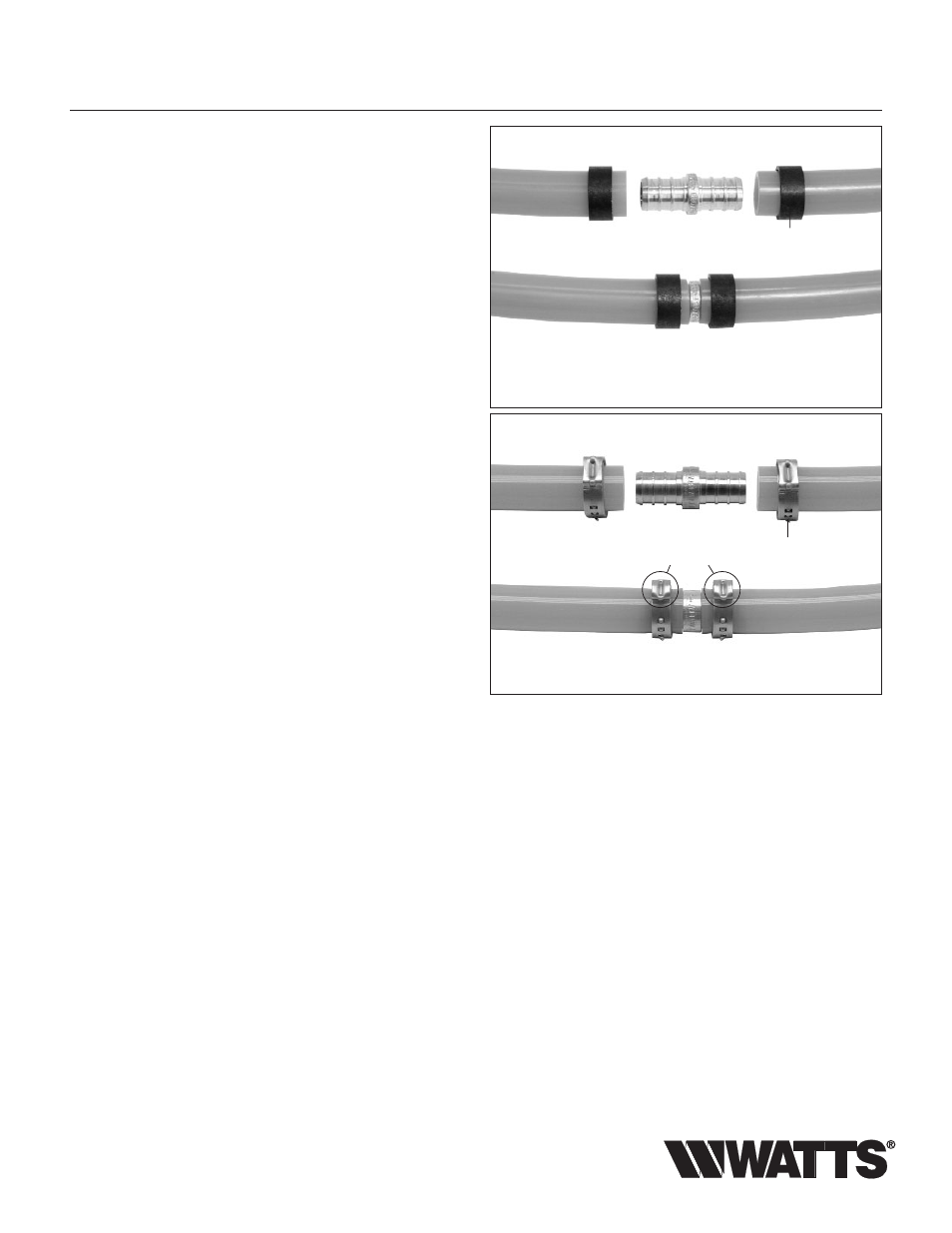

CrimpRing

™

Repair

1. Slide CrimpRings

™

over PEX and PEX onto CrimpRing

™

Coupling.

2. Compress CrimpRing

™

with CrimpMaster

™

or RingMaster

™

.

3. Check compression with Go–No-Go gauge.

CrimpRing

™

Brass Coupling Copper CrimpRing

™

PEX

PEX

Crimp

Brass Coupling

CinchClamp

™

“Pinched” Tabs

PEX

PEX

1. Slide CinchClamps

™

over PEX and PEX onto Coupling.

2. “Pinch” the top tab of the CinchClamp

™

with the CinchTool

™

.

CinchClamp

™

Repair