Iv. replacement parts list, V. membrane replacement, Ro system troubleshooting – Watts PWR4022 User Manual

Page 13

13

RO System Troubleshooting

PRoblem

coRRective action

General

high Product Water tDs

Membrane expanded.

Replace membrane.

Membrane attack by chlorine

Carbon pre-filter may be exhausted. Replace with a new cartridge.

Clogged pre-filter-creates pressure drop and low reject flow.

Replace pre-filter cartridge.

Feed pressure too low.

Feed pressure must be at least 20psi.

Insufficiently flushed post-filter cartridge.

Flush post-filter with pure water.

Brine seal on membrane leaks.

Determine if seal or o-ring is bad. Replace as needed.

no Product Water or not enough Product Water

Feed water shut off.

Turn on feed water.

Low feed pressure. Feed pressure must be at least 20psi.

Consider booster pump.

Pre-filter cartridge clogged.

Replace pre-filter cartridge.

Membrane fouled.

Determine and correct cause; replace membrane.

Product check valve stuck.

Replace check valve fitting.

Low pump discharge pressure

Open pump discharge valve, replace pump

item numbeR

DescRiPtion

1

Pre filter housing 20" Big Blue

2

RO Membrane Pressure Vessels 4" x 80" FRP

3

Pressure Gauge, 2", 0-100psi, Dry

4

Pressure Gauge, 2

1

⁄

2

", 0-400psi, LF

5

Flow Meter 1-10 gpm (product)

6

Flow Meter 1-10 gpm (reject)

7

Motor Starter Contactor, 16 amps, 24 volt coil

8

Overload Relay 8 - 14 amps

9

Pump with TEFC 3ph 7.5hp motor

10

Low-pressure Switch, 6.5psi

11

Inlet Solenoid Valve, 1”, 24 volt coil

12

Watts Brand 4 x 40 RO Membranes

13

CI 1000 RO Controller

14

Conductivity Probe

15

Autoflush Solenoid Valve,

1

⁄

2

", Brass, 24 volt coil.

IV. Replacement Parts List

A list of common replacement parts is provided below. All of these

parts are not used on every system and all of the parts are not listed.

Contact you dealer for replacement parts assistance.

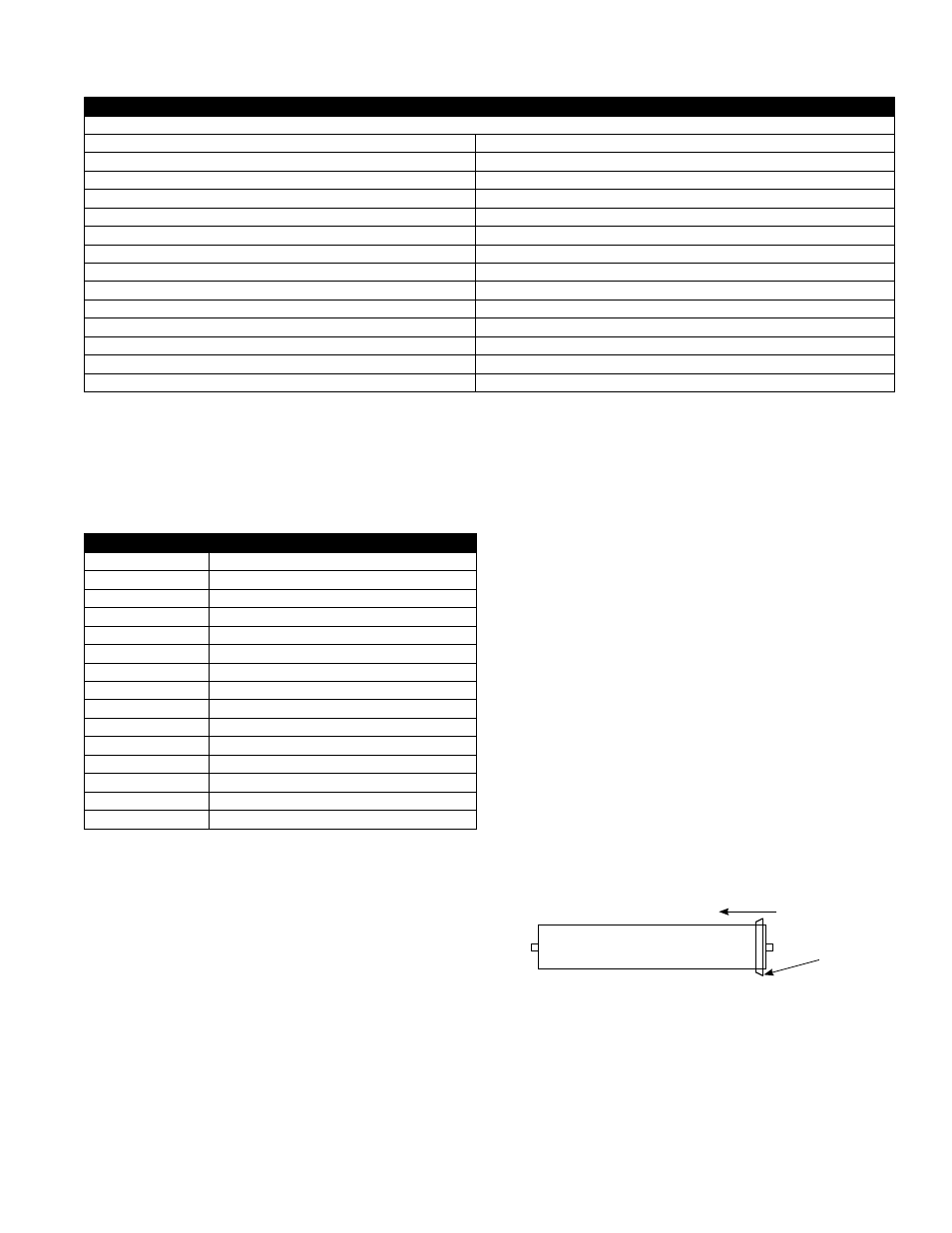

V. Membrane Replacement

1. Turn off the system and close the feed water shutoff valve.

2. Disconnect the membrane feed hoses by loosing the brass fit-

tings between the end of the hoses and the pressure vessel end

caps.

3. Remove the retaining rings from the pressure vessels.

4. Push the old membrane out of the vessel in the direction of the

feed flow. (See flow arrows on the right side of figure #1)

5. Record the serial numbers of the new membranes.

6. Lightly lubricate the brine seals on the new membranes with

clean water.

7. Install the new membranes in the direction of flow with the brine

seal end going in last.

Note: Be sure to install the interconnectors between the mem-

branes in each pressure vessel.

8. Lightly lubricate the end cap internal and external O-rings with

glycerin.

9. Install the end caps and secure them with the retaining rings.

10. Install the membrane feed hoses.

11. Verify that all retaining rings are installed.

12. Follow the start up procedure in section III-D.

Brine

Seal

Flow Direction

Membrane