Watts LF709 User Manual

Series lf709, Lead free, Double check valve assemblies

LF709 LF

ES-LF709L

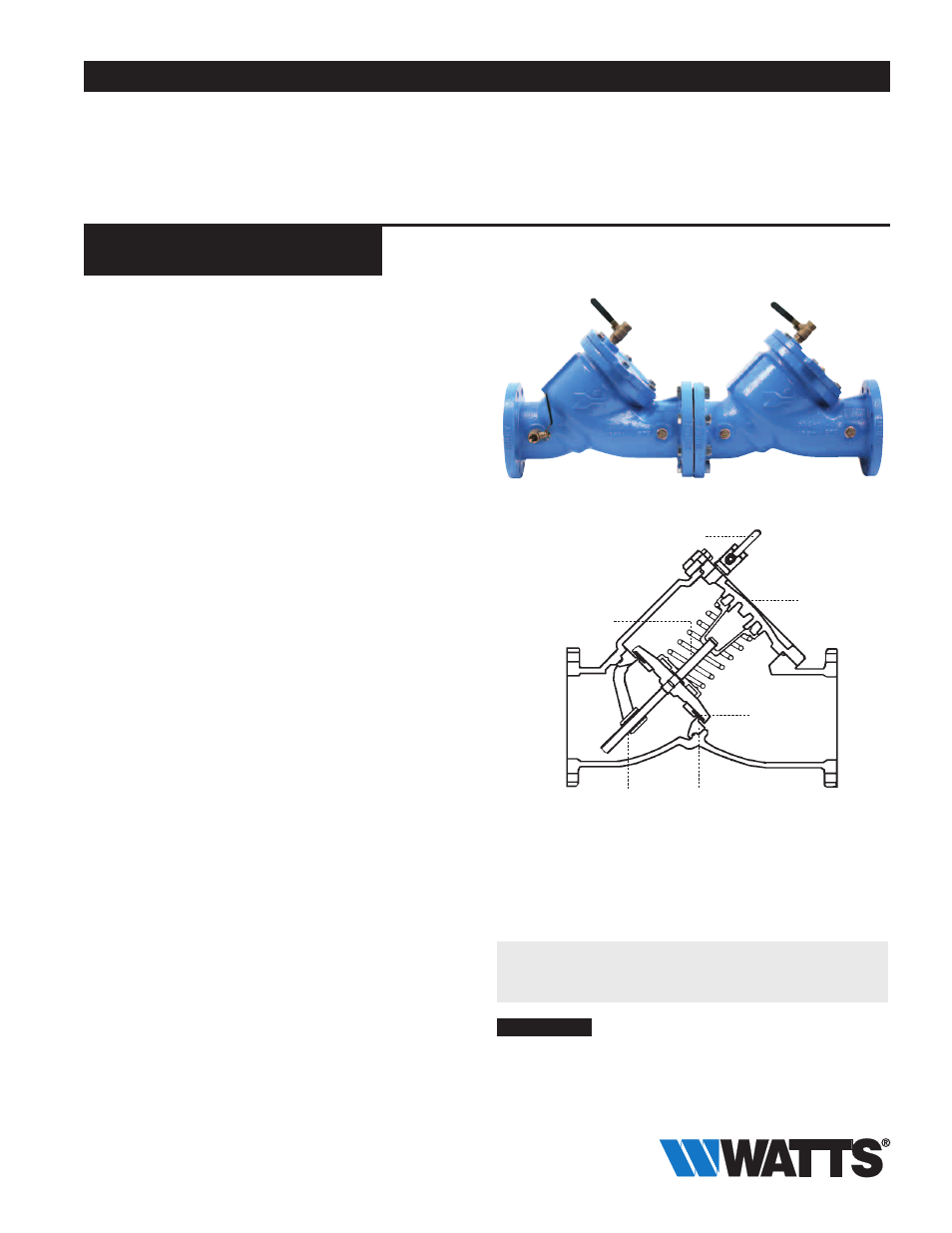

Ball Valve Test Cock

Check Assembly

Module

Bolted Cover

Replaceable

Resilient

Disc

Replaceable Seat

Lower Stem

Guide

For Non-Health Hazard Applications

Now Available

WattsBox Insulated Enclosures.

For more information, refer to literature ES-WB.

Series LF709

Double Check Valve Assemblies

Sizes: 2

1

⁄

2

" – 10" (65 – 250mm)

Series LF709 Double Check Valve Assemblies are designed

to prevent the reverse flow of polluted water from entering into

the potable water system. This series can be applied, where

approved by the local authority having jurisdiction, on non-health

hazard installations. Series LF709 features a modular check

design concept to facilitate easy maintenance. Check with local

jurisdictional authority as to installation requirements. The LF709

features Lead Free* construction to comply with Lead Free*

installation requirements.

Features

• Replaceable stainless steel seats

• Maximum flow at low pressure drop

• Design simplicity for easy maintenance

• No special tools required for servicing

• Captured spring assemblies for safety

• Approved for vertical flow up installation

Models

Suffix:

NRS – non-rising stem resilient seated gate valves

OSY – UL/FM outside stem and yoke resilient seated gate valves

S-FDA – FDA epoxy coated strainer

QT-FDA – FDA epoxy coated ball valve shutoffs

LF – without shutoff valves

Specifications

A Double Check Valve Assembly shall be installed at referenced

cross-connections to prevent the backflow of polluted water

into the potable water supply. The cross-connections shall be

determined by local inspection authority for use where a high

hazard situation does not exist. Valve shall feature modular check

assemblies with center stem guiding. Each check module shall

have a captured spring and be accessible through a bolted cover

plate. Seats shall be replaceable without special tools. It shall be a

complete assembly including tight-closing resilient seated shutoff

valves, test cocks, and a strainer is recommended. The Lead

Free* Double Check Assemblies shall comply with state codes

and standards, where applicable, requiring reduced lead content.

The assembly shall meet the requirements of ASSE No. 1015;

AWWA C510-92; CSA B64.5 and UL Classified File No. EX3185.

Approved by the Foundation for Cross-Connection Control and

Hydraulic Research at the University of Southern California. As-

sembly shall be a Watts Series LF709.

Check Assembly Module

Series LF709 features a modular design concept which facili-

tates complete maintenance and assembly by retaining the

spring load. Also, the first and second check module are identi-

cal and can be interchanged.

LEAD FREE

*

* The wetted surface of this product contacted by consumable water

contains less than 0.25% of lead by weight.

Watts product specifications in U.S. customary units and metric are approximate and are provided for reference only. For precise measurements,

please contact Watts Technical Service. Watts reserves the right to change or modify product design, construction, specifications, or materials with-

out prior notice and without incurring any obligation to make such changes and modifications on Watts products previously or subsequently sold.

Job Name –––––––––––––––––––––––––––––––––––––––––––

Contractor ––––––––––––––––––––––––––––––––––––––––––––

Job Location –––––––––––––––––––––––––––––––––––––––––

Approval –––––––––––––––––––––––––––––––––––––––––––––

Engineer –––––––––––––––––––––––––––––––––––––––––––––

Contractor’s P.O. No. ––––––––––––––––––––––––––––––––––

Approval –––––––––––––––––––––––––––––––––––––––––––––

Representative ––––––––––––––––––––––––––––––––––––––––

NOTICE

Inquire with governing authorities for local installation requirements