Watts 007DCDA User Manual

Series 007dcda, Double check detector assemblies, For non-health hazard fire applications

For Non-Health Hazard Fire Applications

ES-007DCDA

2

1

/

2

" (65mm)

007DCDA

Now Available

WattsBox Insulated Enclosures.

For more information, refer to literature ES-WB.

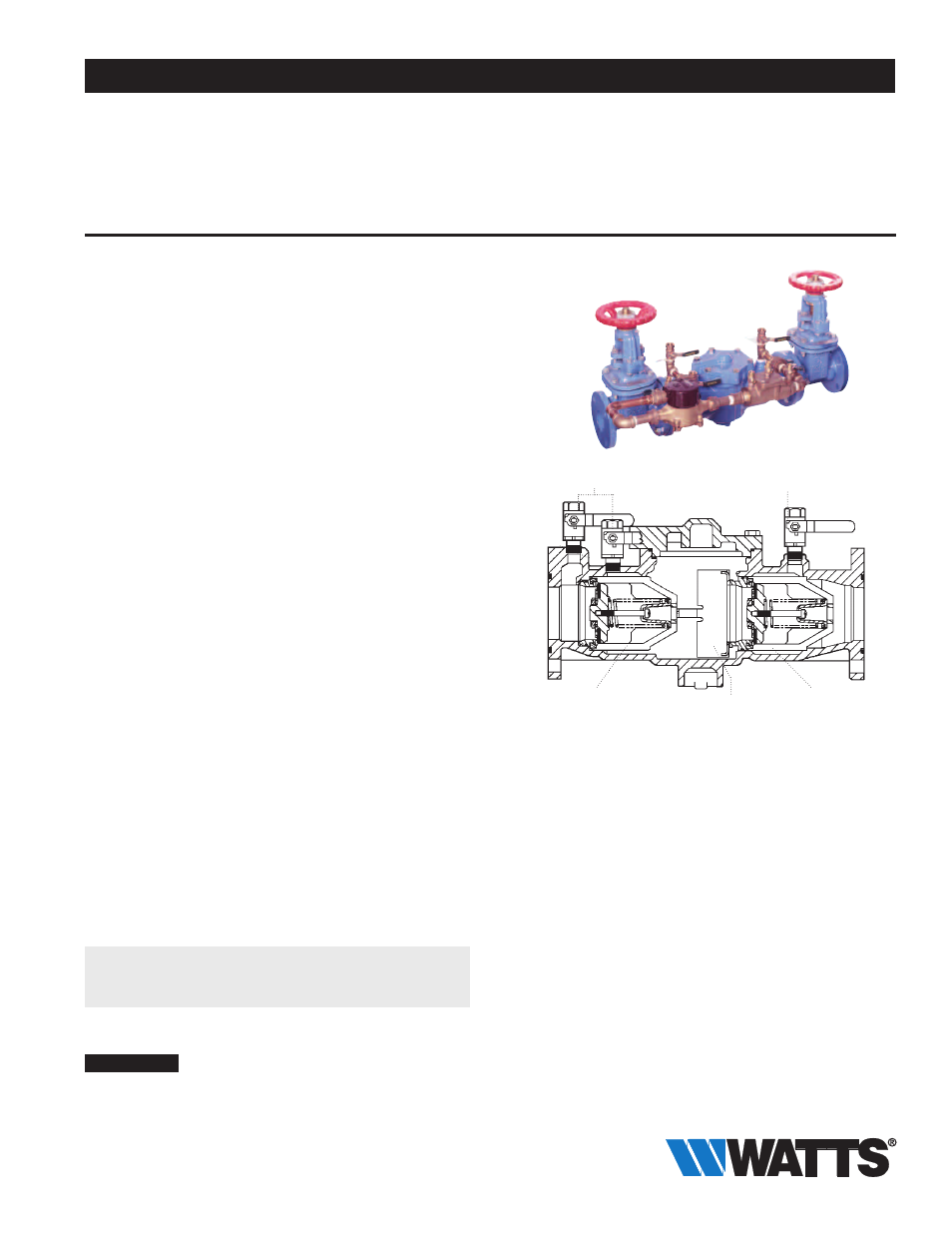

Test Cock

Retainer

2nd Check

Module

1st Check

Module

Test Cock

Series 007DCDA

Double Check Detector Assemblies

Sizes: 2

1

⁄

2

" – 3" (65 – 80mm)

Series 007DCDA Double Check Detector Assemblies are designed

exclusively for use in accordance with water utility authority on non-

health hazard containment requirements. It is mandatory to prevent

the reverse flow of fire protection system substances, i.e., glycerin

wetting agents, stagnant water and water of non-potable quality

from being pumped or siphoned into the potable water line.

Benefits: Detects leaks…with emphasis on the cost of unaccount-

able water; incorporates a meter which allows the water utility to:

• detect underground leaks that historically create great annual

cost due to waste.

• provide a detection point for unauthorized use. It can help locate

illegal taps.

Modular check design concept facilitates maintenance and assem-

bly access. All sizes are standardly equipped with resilient seated

OSY shutoff valves and

5

⁄

8

" x

3

⁄

4

" (16 x 19mm) meter.

Features

• Fused epoxy coated cast iron unibody 2

1

⁄

2

" – 3" (65 – 80mm)

• Replaceable seats

• Maximum flow at low pressure drop

• Compact for ease of installation

• Design simplicity for easy maintenance

• No special tools required for servicing

• Bronze body ball valve test cocks

• Modular spring loaded checks

• Furnished with bronze

5

⁄

8

" x

3

⁄

4

" (16 x 19mm) meter

Watts product specifications in U.S. customary units and metric are approximate and are provided for reference only. For precise measurements,

please contact Watts Technical Service. Watts reserves the right to change or modify product design, construction, specifications, or materials with-

out prior notice and without incurring any obligation to make such changes and modifications on Watts products previously or subsequently sold.

Specifications

A Double Check Detector Assembly shall be installed on fire protec-

tion systems when connected to a potable water supply. Degree of

hazard present is determined by the local authority having jurisdic-

tion. The backflow preventer shall be a complete assembly includ-

ing UL listed resilient seated OSY shutoff valves and four test cocks.

The test cocks located on the backflow preventer shall be mounted

at the top of the valve to reduce clearance problems and to assist

in the evacuation of air from the assembly. The assembly shall

consist of two independently operating modular poppet-type check

valves. The check valves shall utilize captured springs and shall

have replaceable seats. The checks shall be double-guided, both

along the outside edge of the check module and through the center

stem assembly. The seats shall be replaceable without the use of

special tools. Seat retention shall be done by the use of an inter-

locking bayonet-style cage and the use of threaded seats or seat

screws is prohibited. Access to the internal check assemblies shall

be via a single top entry cover. The cover shall be securely held in

place by stainless steel bolts. Where applicable the unit shall be FM

approved with FM approved OSY resilient seated shutoff valves.

The assembly shall include an auxiliary bypass line consisting of an

approved backflow preventer and water meter.

The assembly shall be listed or approved under the requirements of

ASSE Std. 1048, AWWA Std. C510-92 and CSA B64.5. Approved

by the Foundation for Cross-Connection Control and Hydraulic

Research at the University of Southern California. The assembly

shall be a Watts Regulator Company Series 007DCDA.

Job Name –––––––––––––––––––––––––––––––––––––––––––

Contractor ––––––––––––––––––––––––––––––––––––––––––––

Job Location –––––––––––––––––––––––––––––––––––––––––

Approval –––––––––––––––––––––––––––––––––––––––––––––

Engineer –––––––––––––––––––––––––––––––––––––––––––––

Contractor’s P.O. No. ––––––––––––––––––––––––––––––––––

Approval –––––––––––––––––––––––––––––––––––––––––––––

Representative ––––––––––––––––––––––––––––––––––––––––

NOTICE

Inquire with governing authorities for local installation requirements