Lassic, Eries, Materials – Watts LFF1115 User Manual

Page 2

2

C

lassiC

s

eries

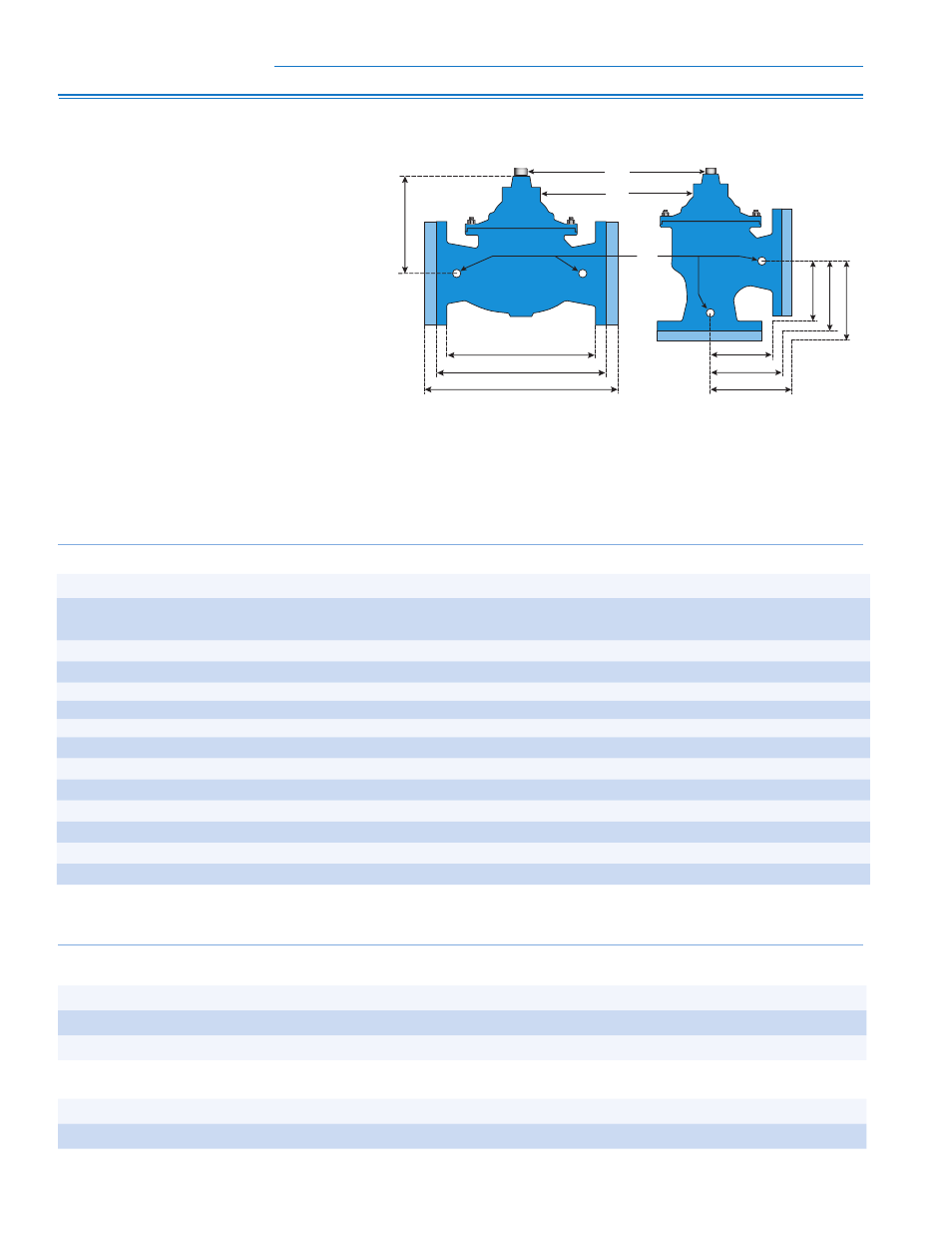

LFF115 (Globe)

LFF1115 (Angle)

Body & Cover:

Ductile Iron ASTM A536

Coating:

NSF Listed Fusion

Bonded Epoxy Lined

and Coated

Trim:

316 Stainless Steel

Elastomers:

Buna-N (standard)

EPDM

(optional)

Viton (optional)

Stem, Nut &

Stainless Steel

Spring:

Materials

L

M

D

A

B

C

E

F

G

H I J

K

Globe

Angle

Operating Pressure

Operating Temperature

Pilot System

Tubing & Fittings

Threaded = 400 psi

Buna-N: 160°F Maximum

Reducing Control

Copper / Brass (Standard)

150 Flanged = 250 psi

EPDM: 300°F Maximum

20-175 psi (Standard)

Stainless Steel (Optional)

300 Flanged = 400 psi

Viton: 250°F Maximum

0-30 psi (Optional)

100-300 psi (Optional)

Valve Cover Chamber Capacity

Valve Travel

Dimensions

A

B

C

D

E

F

G

H

I

J

K

L

M

VALVE

SIZE

GLOBE

THRD.

GLOBE

150#

GLOBE

300#

COVER TO

CENTER

ANGLE

THRD.

ANGLE

150#

ANGLE

300#

ANGLE

THRD.

ANGLE

150#

ANGLE

300#

PORT

SIZE

PORT

SIZE

PORT

SIZE

SHIPPING

WEIGHTS*

1-1/4

7-1/4

3-1/2

3-1/4

1-7/8

1/4

1/2

1/8

15

1-1/2

7-1/4

8-1/2

9

3-1/2

3-1/4

4

1-7/8

4

1/4

1/2

1/8

15

2

9-3/8

9-3/8

10

4-15/16

4

4

4-1/4

4

4

4-1/4

1/2

1/2

1/4

35

2-1/2

11

11

11-5/8

7

5-1/2

5-1/2

5-13/16

4

4

4-5/16

1/2

1/2

3/8

65

3

10-1/2

12

13-1/4

7

5-1/4

5-3/4

6-1/8

5-1/4

5-3/4

6-1/8

1/2

1/2

3/8

95

4

15

15-5/8

8-5/8

6-3/4

7-1/8

6-3/4

7-1/8

1/2

1/2

3/8

190

6

20

21

11-3/4

8-1/2

8-7/8

8-1/2

8-7/8

1/2

1/2

1/2

320

8

25-3/8

26-3/8

15-3/4

11

11-1/2

11

11-1/2

1/2

1

1/2

650

10

29-3/4

31-1/8

18-3/4

14-7/8

15-5/8

14-7/8

15-5/8

1

1

1

940

12

34

35-1/2

20-5/8

17

17-3/4

17

17-3/4

1

1

1

1500

14

39

40-1/2

22-1/4

1

1

1

1675

16

41-3/8

43-1/2

26-1/4

1

1

1

3100

*Estimated in lbs.

Valve Size (in)

1-1/4

1-1/2

2

2-1/2

3

4

6

8

10

12

14

16

fl.oz.

4

4

4

10

10

22

70

U.S. Gal

1-1/4

2-1/2

4

6-1/2

9-1/2

Valve Size (in)

1-1/4

1-1/2

2

2-1/2

3

4

6

8

10

12

14

16

Travel (in)

3/8

3/8

1/2

5/8

3/4

1

1-1/2

2

2-1/2

3

3-1/2

4