Watts 919 User Manual

Series 919, Reduced pressure zone assemblies, For health hazard applications

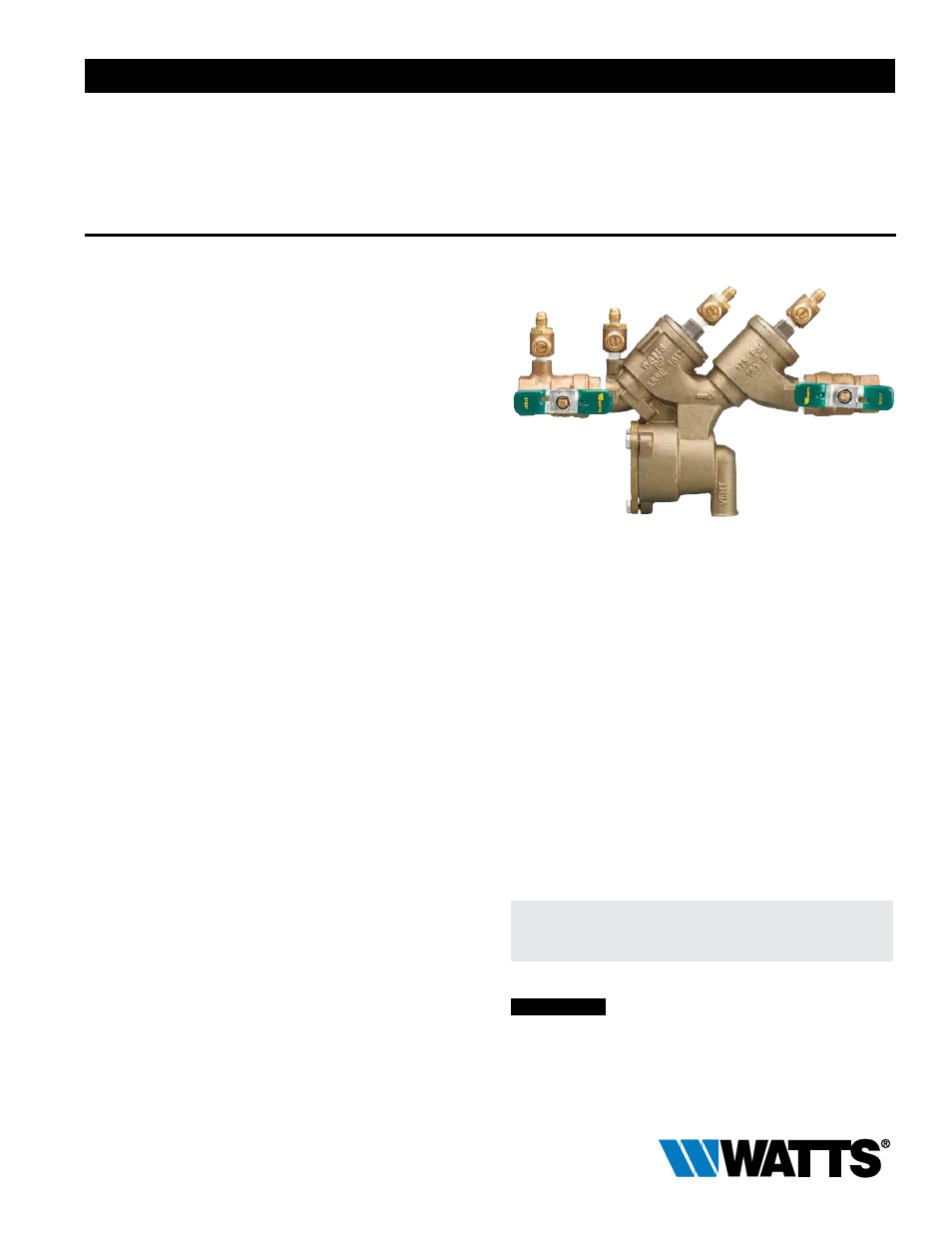

Series 919

Reduced Pressure Zone

Assemblies

Sizes:

1

⁄

4

" – 2" (5 – 50mm)

Series 919 Reduced Pressure Zone Backflow Assemblies are

designed to protect potable water supplies in accordance with

national plumbing codes and water authority requirements. This

series can be used in a variety of installations, including the preven-

tion of health hazard cross-connections or for containment at the

service line entrance.

This series features two poppet style check valves, replaceable

check seats, with an intermediate relief valve. Its compact modular

design facilitates easy maintenance and assembly access. Sizes

1

⁄

4

"

– 1" (5 – 25mm) shutoffs have tee handles.

Features

• Separate access covers for the check valves and relief valve for

ease of maintenance

• Top entry-all check internals easily accessible

• All rubber elastomers of chloramine resistant material

• Check valve poppet assemblies are fully guided by innovative

plastic seat guide

• Replaceable push-in check valve and relief valve seats

eliminates threads from the water way

• EZ twist relief valve cover quarter-turn locking joint captures

the spring load during repair to facilitate disassembly

• Innovative check valve plastic cover bushing provides trouble

free guiding of the check valve poppet

• Bottom mounted relief valve provides reduced installation clear-

ances

• Compact, space saving design

• No special tools required for servicing

• Top mounted test cocks for ease in testing and reduced installa-

tion clearances

• Standardly furnished with NPT body connections

Specifications

A Reduced Pressure Zone Assembly shall be installed at each

potential health hazard location to prevent backflow due to back-

siphonage and/or backpressure. The assembly shall consist of a

pressure differential relief valve located in a zone between two posi-

tive seating check valves. Seats and seat discs shall be replace-

able in both check valves and the relief valve without the use of

special tools. Service of all internal check valve components shall

be through top mounted access bronze covers threaded to the

main valve body. The check valve poppet assembly shall be guided

via the use of a corrosion resistant plastic guide. The check valve

and relief valve seats shall be push-in type. The relief valve cover

shall be bronze construction secured with stainless steel bolts and

shall utilize a quarter-turn locking joint to capture the spring load

of the relief valve. The relief valve shall have an internal sensing line

to sense the inlet water supply. All rubber elastomers shall be of

chloramine resistant material. The assembly shall also include two

resilient seated isolation valves, four top-mounted resilient seated

test cocks and an air gap drain fitting. The assembly shall be a

Watts Series 919.

For Health Hazard Applications

919QT

3

⁄

4

" (20mm)

Now Available

WattsBox Insulated Enclosures.

For more information, refer to literature ES-WB.

Watts product specifications in U.S. customary units and metric are approximate and are provided for reference only. For precise measurements,

please contact Watts Technical Service. Watts reserves the right to change or modify product design, construction, specifications, or materials with-

out prior notice and without incurring any obligation to make such changes and modifications on Watts products previously or subsequently sold.

Job Name –––––––––––––––––––––––––––––––––––––––––––

Contractor ––––––––––––––––––––––––––––––––––––––––––––

Job Location –––––––––––––––––––––––––––––––––––––––––

Approval –––––––––––––––––––––––––––––––––––––––––––––

Engineer –––––––––––––––––––––––––––––––––––––––––––––

Contractor’s P.O. No. ––––––––––––––––––––––––––––––––––

Approval –––––––––––––––––––––––––––––––––––––––––––––

Representative ––––––––––––––––––––––––––––––––––––––––

ES-919

NOTICE

Inquire with governing authorities for local installation requirements