Watts R4X40-3 User Manual

Page 5

I. INTRODUCTION

The separation of dissolved solids and water using RO membranes is a pressure driven

temperature dependent process. The membrane material is designed to be as permeable to water

as possible, while maintaining the ability to reject dissolved solids.

The main system design parameters require the following:

Internal flows across the membrane surface must be high enough to prevent settling of fine

suspended solids on the membrane surface.

The concentration of each dissolved ionic species must not exceed the limits of solubility

anywhere in the system.

Pre-treatment must be sufficient to eliminate chemicals that would attack the membrane

materials.

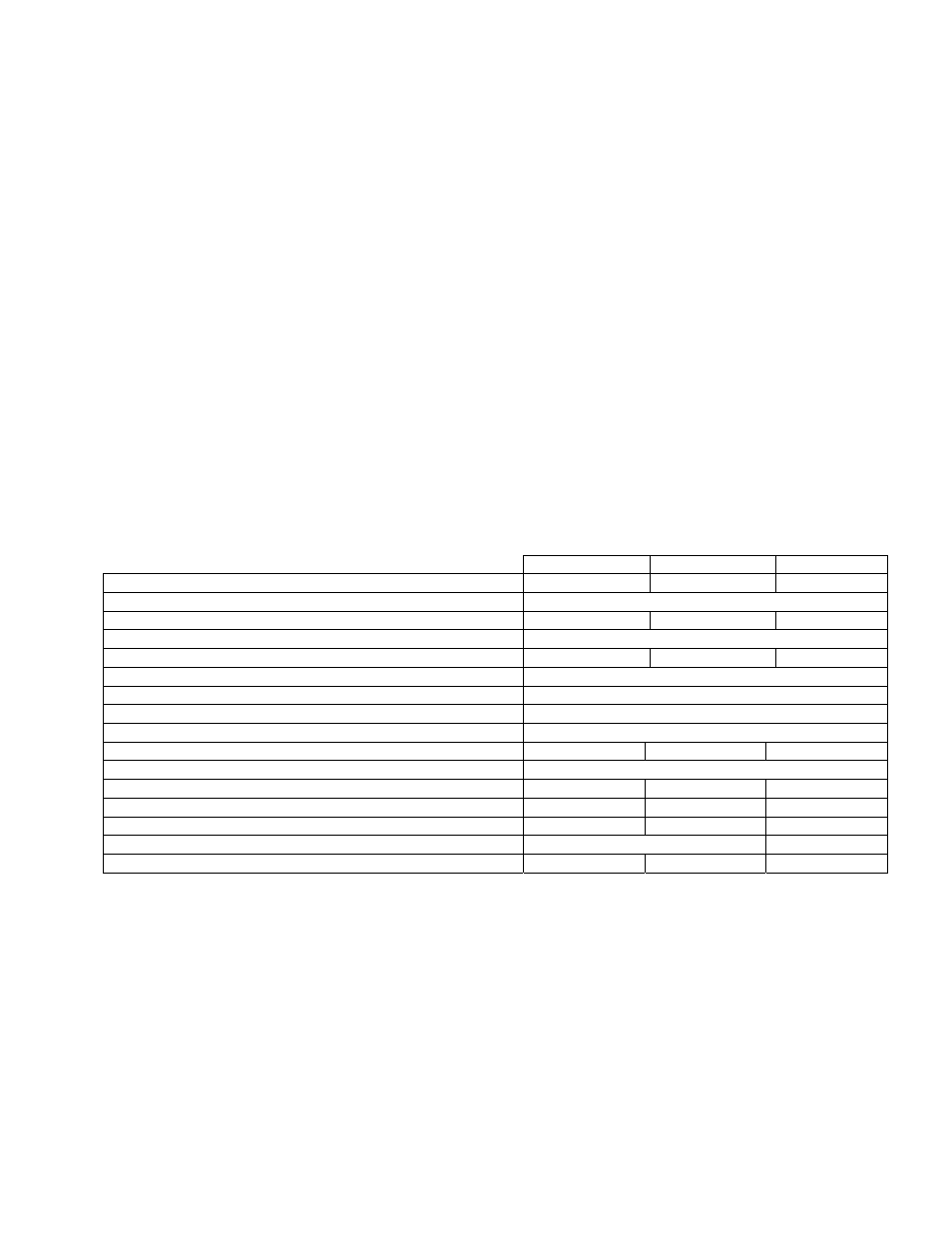

A. SPECIFICATIONS

Notes:

Maximum production based on a feed water of 77°F, SDI < 1, 1000 ppm TDS, and pH 7.

Individual membrane productivity may vary (± 15%). May be operated on other feed waters with reduced

capacity.

Percent Rejection is based on membrane manufactures specifications; overall system percent rejection may

be less.

R4X40-1 R4X40-2 R4X40-3

Maximum Productivity (gallons per day)

2200

4400

6600

Quality (average membrane rejection)

98 %

Recovery (user adjustable)

15 - 75 %

25 – 75%

32 - 75 %

Membrane Size

4” x 40”

Number Of Membranes

1 2 3

Prefilter (system ships with one 5 micron cartridge)

20”

Feed Water Connection

3/4" NPTF

Product Water Connection (tubing OD)

5/8"

Reject Water Connection (tubing OD)

5/8"

Feed Water Required (maximum)

10 gpm

12 gpm

14 gpm

Feed Water Pressure (minimum) 10

psi

Drain Required (maximum)

10 gpm

12 gpm

14 gpm

Electrical Requirement (120 VAC 60 Hz)

8 amps

12 amps

16 amps

Motor Horse Power

3/4 1 1

1/2

Dimensions W x D x H (approximate inches)

20 x 20 x 50

20 x 26 x 50

Shipping Weight (estimated

pounds)

120 150 180