Watts R4X40-3 User Manual

Page 2

S-WQ-R4X40 1305

© 2013 Watts

usa: Tel. (800) 659-8400 • www.watts.com

canada: Tel. (888) 208-8927 • www.watts.ca

A Watts Water Technologies Company

introduction

Watts Reverse Osmosis (R0) Systems are designed to provide the

commercial and industrial user with the most trouble free, cost effec-

tive and reliable form of water treatment available, by providing every

option necessary for a successful installation.

Principles of Reverse osmosis

Watts R0 systems employ thin film composite spiral wound membrane

elements for superior performance. To simply describe the process,

pump pressure is used to supply source water to reverse osmosis

membranes. These special membranes allow only high quality water

to permeate them. In turn, they reject metals, salts, ionic and organic

impurities that are processed to waste.

Suspended solids are removed by pre-filters, which are standard

components on all Watts RO systems.

Water temperature

Product water quality and production of any RO system is depen-

dent on pressure and temperature. Watts RO systems are rated at

standard conditions of 77°F (25°C), 60 psi (4.2 bar) inlet pressure and

1,000 TDS feed water quality. Higher temperatures will result in more

water passing through the membranes and increased water produc-

tion. As a rule , at given pressures and TDS levels, for each one-

degree change in water temperature the change in water production is

approximately 2%.

WateR temPeRatuRe

PRoDuctioN FactoR*

°F

°c

(Using thin film membranes)

40

4

0.48

50

10

0.60

60

16

0.73

70

21

0.88

77

25

1.00

80

27

1.06

90

32

1.26

*percent of rated production

Water pressure

Watts

®

commercial RO systems require a minimum of 10 psi feed

pressure to function properly. The maximum pressure is 90 psi, and a

pressure regulator must be utilized over 90 psi to reduce feed water

pressure.

Feed / source water inlet requirements

The source water requirements shown below are essential for proper

operation:

iNlet FeeD WateR ReQuiRemeNts

Factor

Requirements

Hardness

< 1 grain per gallon

Free chlorine

0 ppm

T.D.S.

<1,000 ppm

S.D. I.

<5

pH

3-11

Iron

<0.01 ppm

Silica

<25 ppm

Manganese

<0.05 ppm

Turbidity

<1 NTU

Temperature

35°F - 95°F (2°C - 35°C)

Pressure

10-90 psi (2.8- 5.6 bar)

Note: Pretreatment may be required if the above parameters are not

met. Failure to meet feed water requirements may foul membranes,

void the warranty and possibly make it necessary to down-rate perfor-

mance.

All specifications listed are based on an average of 1,000 TDS feed

water, 77°F (25°C) temperature and 60 psi (4.2 bar) pressure. Typically,

higher-pressure differentials and higher temperatures increase water

production and water quality. Maximum pressure and temperature

limits must be observed.

1. system location

The RO system should be located on a level surface in an area

sheltered from sun, wind and rain. The temperature in this area should

be maintained, and should not fall below 35°F (2°C), nor greater than

95°F (35°C). If these limits are exceeded, damage to components

may result and the warranty may be considered void. It is important

to allow sufficient space around the unit so maintenance can easily be

performed.

2. Plumbing

The high-pressure pumps used require a continuous flow of water to

the system. Minimum feed pressure is 10 psi.

3. Feed water

Piping for feed water to the RO system should be either copper or

plastic. Iron and carbon steel pipe will increase the iron content of the

raw feed water and adversely affect the RO system's performance.

Temperature of the feed water must not exceed 95°F (35°C).

4. Product water (permeate) line connection

Connect the product water (permeate) line to the manifold on the back

side of the system. This line should not have valves and should run as

directly as possible to the storage tank.

5. concentrate (waste) line connection

Connect the waste line (concentrate) to the manifold on the back side

of the system. The waste from the system should not have valves and

should have an air break between it and the building drain system.

The tubing or piping used for discharge of the concentrate should be

run to an open drain in a free and unrestricted manner.

6. electrical

The customer must provide a properly sized electrical service.

level controls

In most installations it is necessary to use the level switch connec-

tor wire to install a level control or an electrical switch to turn the RO

system on and off based on the water level in the storage tank.

Pumps

Never let pumps run dry. Operating pumps without sufficient feed

water will cause damage. Feed pumps with filtered water only.

Pre-filtration

All Watts® RO systems come with particulate pre-filters to remove

suspended particles down to five (5) micron in size. Filter cartridges

should be changed at end of filter life, due to lack of filtering perfor-

mance, or whenever a 15psi pressure drop or greater is experienced

during normal operation, whichever comes first.

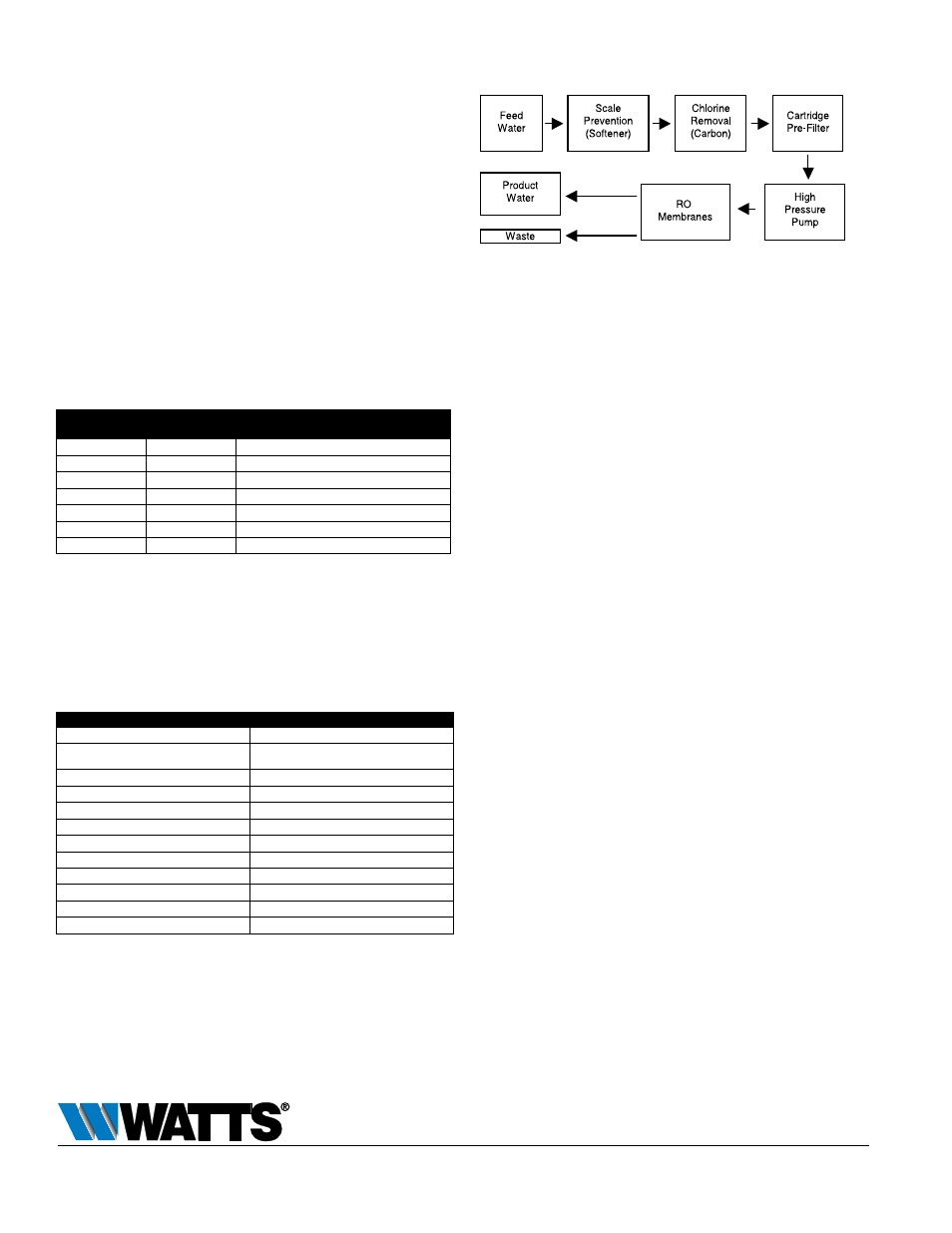

General Ro Process Diagram