Test procedure for reduced pressure assembly, Test no. 4 - pressure differential relief valve, Test no. 1 - check valve no. 2 – Watts TK-99E User Manual

Page 3: Test no. 2 - shutoff valve no. 2, Test no. 3 - to test no. 1 check valve

3

Test Procedure for Reduced Pressure Assembly

A. All needle valves must be closed on test kit.

B. Open test cock No. 4 and flush test cocks Nos. 1, 2 and 3 on reduced pressure assembly then close test cock No. 4.

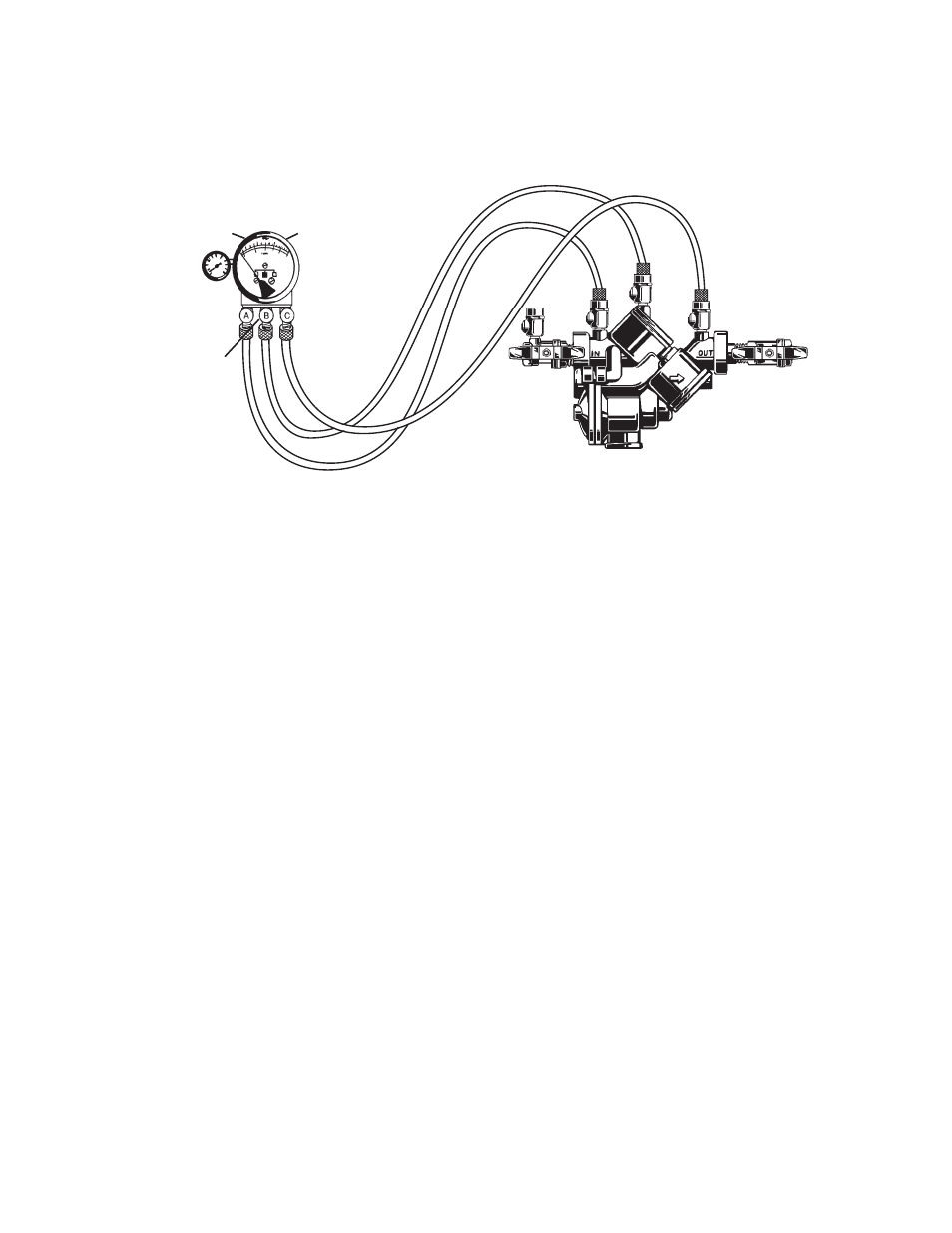

C. Attach hoses as shown. Bleed air from kit, close No. 2 shutoff.

Test No. 4 - Pressure Differential Relief Valve

Purpose: To test operation of pressure differential relief valve.

Requirements: The pressure differential relief valve must

operate to maintain the “zone” between the two check valves

at least 2 PSI less than the supply pressure.

Step 1: Close needle valve “C” bypass (yellow).

Step 2: Open needle valve “A” high side (red).

Step 3: Open needle valve “B” low (blue) very slowly until the

differential gauge needle starts to drop.

Step 4: Hold the valve at this position and observe the gauge

reading at the moment the first discharge is noted

from the relief valve. Record this as the opening differ-

ential pressure of the relief valve. Note: it is important

that the differential gauge needle drops slowly.

Step 5: Close test cocks Nos. 2 and 3. Remove hose from

test cocks Nos. 2 and 3.

Step 6: Use bypass hose (yellow) to relieve pressure from

test kit by opening needle valve “A”, “B” and “C” and

bleed valves “A” and “B”.

Step 7: Remove all test equipment and open No. 2 shutoff

valve of the device.

Test No. 1 - Check Valve No. 2

Purpose: To test check valve No. 2 for tightness against

reverse flow.

Requirements: Valve must be tight against reverse flow under

all pressure differentials.

Step 1: Slowly open the needle valve “A” high side (red) and

“C” bypass (yellow). Keep the “B” low (blue) closed.

Step 2: Open test cock No. 4. Open test cock No. 2 and test

cock No. 3 after opening test cock No. 4.

Step 3: Indicated pressure differential will decrease slightly.

If pressure differential continues to decrease (until

the vent opens) the No. 2 check valve is reported as

“leaking”.

Test No. 2 - Shutoff Valve No. 2

Purpose: To test shutoff valve No. 2 for tightness.

Step 1: After passing Test No. 1, continue to test No. 2 by

closing test cock No. 2.

Step 2: The indicated pressure differential will decrease

slightly. If pressure differential continues to decrease

(approaching “zero”) the No. 2 shutoff valve is re-

ported to be “leaking”.

Note: A leaking No. 2 shutoff

will give a false reading in tests No. 3 and 4.

Test No. 3 - To test No. 1 Check Valve

Purpose: To test check valve No. 1 for tightness.

Requirements: Valve must be tight against reverse flow under

all pressure differentials.

Step 1: Close needle valve “A” high side (red) and open test

cock No. 2.

Step 2: Close test cock No. 4. Disconnect bypass hose (yel-

low) at test cock No. 4.

Step 3: Open needle valve “B” low (blue) and “C” bypass

(yellow), bleeding to atmosphere, then closing needle

valve “B” (blue) restores the system to a normal static

condition.

Step 4: Observe the pressure differential gauge. If there is a

decrease in the indicated value, the No. 1 check valve

is reported as “leaking”.

Bleed Valve A

Bleed Valve B

High

(red)

Low

(Blue)

Bypass

(yellow)

No. 2

Shutoff

909 shown