Watts SAN89 User Manual

Page 2

No. N93S, N193S, N93D, N193D

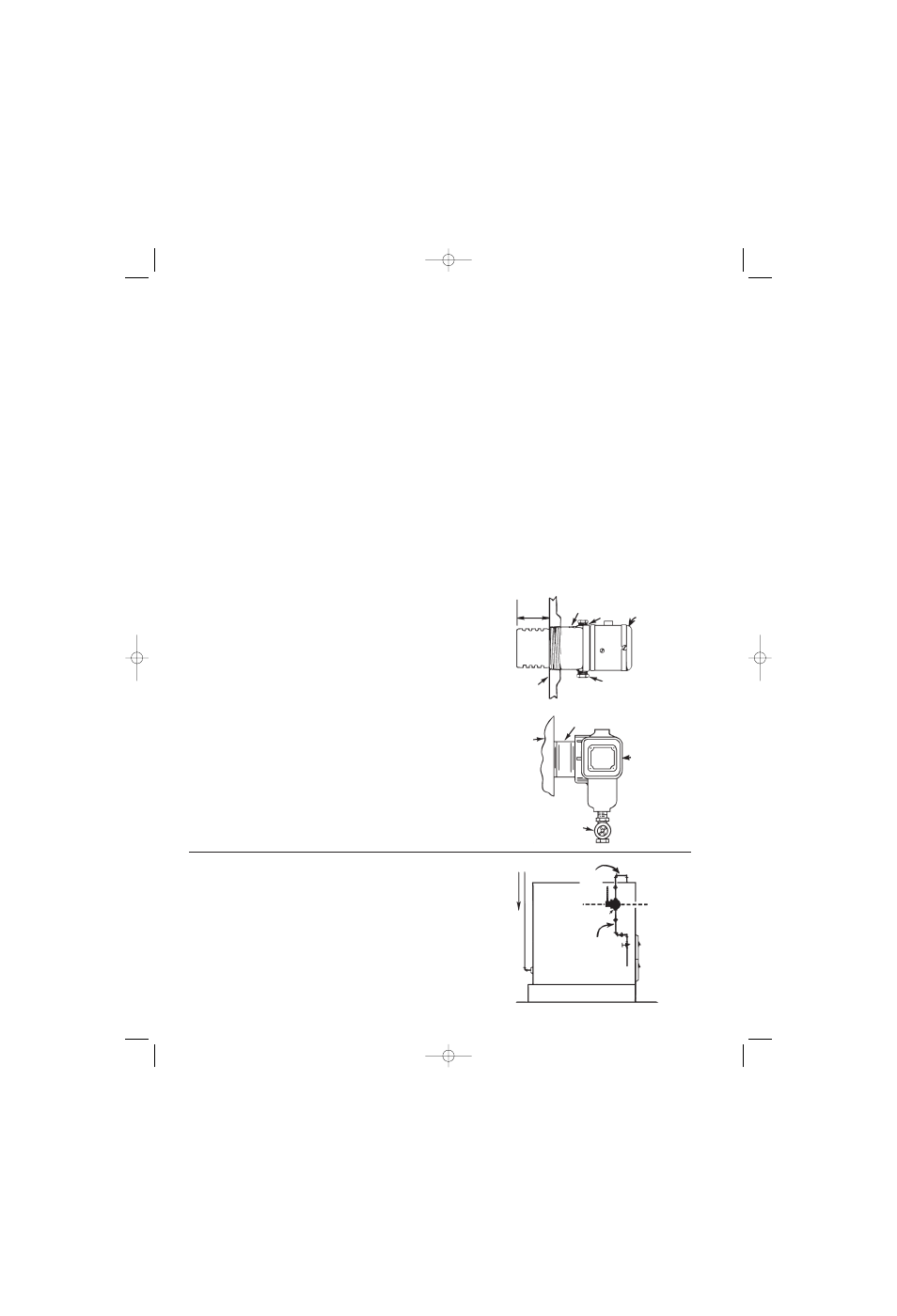

Attach cut-off to the boiler by screwing into the 2

1

⁄

2

" tapping provided,

make up tight with the "TOP" marking uppermost and the adjacent flat

edge of the square flange is exactly level. Before installing No. N93S,

N93D, be sure that there is a minimum distance of 2

1

⁄

4

" between the

inside of the boiler shell and any wall or other protrusion inside the boil-

er. (See Figure 1.) Maximum Steam Pressure 15 lbs.

No. N101S, N101D

Attach cut-off to boiler as in Fig. 2 using a 2

1

⁄

2

" close or space nipple

to suit installation requirements. Make up tight with float chamber lev-

elled in position shown. Attach drain valve. Maximum Steam Pressure

15 lbs.

No. N50S, N50D, N501S, N501D

Watts Series N50 and N501 are designed with a heavier float and bel-

lows construction for protection of hot water space heating boilers

against emergency low water conditions. Float chamber has 1" female

top and bottom connections, for equalizing pipe connection. (See

Figure 3). Maximum Boiler Pressure 50 lbs. @ 250°F.

For installation of N501, see Figure 2.

with Single Switch Assembly. (See Page 4)

with "DUAL" (Two) Switch Assembly. (See Page 3)

This line of cut-offs was designed for boilers where a 2

1

⁄

2

" pipe tapping is provided for the low water cut-off

and where space is limited by the boiler jacket. For boilers that do not have this tapping, use WATTS No.

N89S, N89D which is made for gauge glass connection.

Special Notice

Before leaving the job, it is recommended that the installation of the cut-off be checked under actual working conditions;

this will reveal any installation irregularities. To check, turn on switch to burner and if water in boiler is at or above

the water line, the cut-off will allow the burner to start. Now lower the water line by draining off water from

the boiler; if the cut-off is wired and installed correctly, the burner will shut off when the water level drops to

approximately

3

⁄

8

" below the normal water line.

Float chamber should be flushed at least once every month or more often to remove any accumulated sediment by

opening drain valve where installed or removing drain plug.

Insertion

Length

2

1

⁄

4

"

Marked Top

N93

N193

Level

Fig.1

N93

Only

Inside Boiler Shell

Drain Plug

Boiler

2

1

⁄

2

" Nipple

N101

N501

Fig. 2

Drain Valve

Supply

No. N50

Fig. 3

Equalizing

Pipe

Equalizing

Pipe

Cut-off Line

Built-in Cut-offs

No. N93S, N193S, N101S

No. N93D, N193, N101D

Instructions for Installing

IS-N89.qxd 9/15/08 2:18 PM Page 2