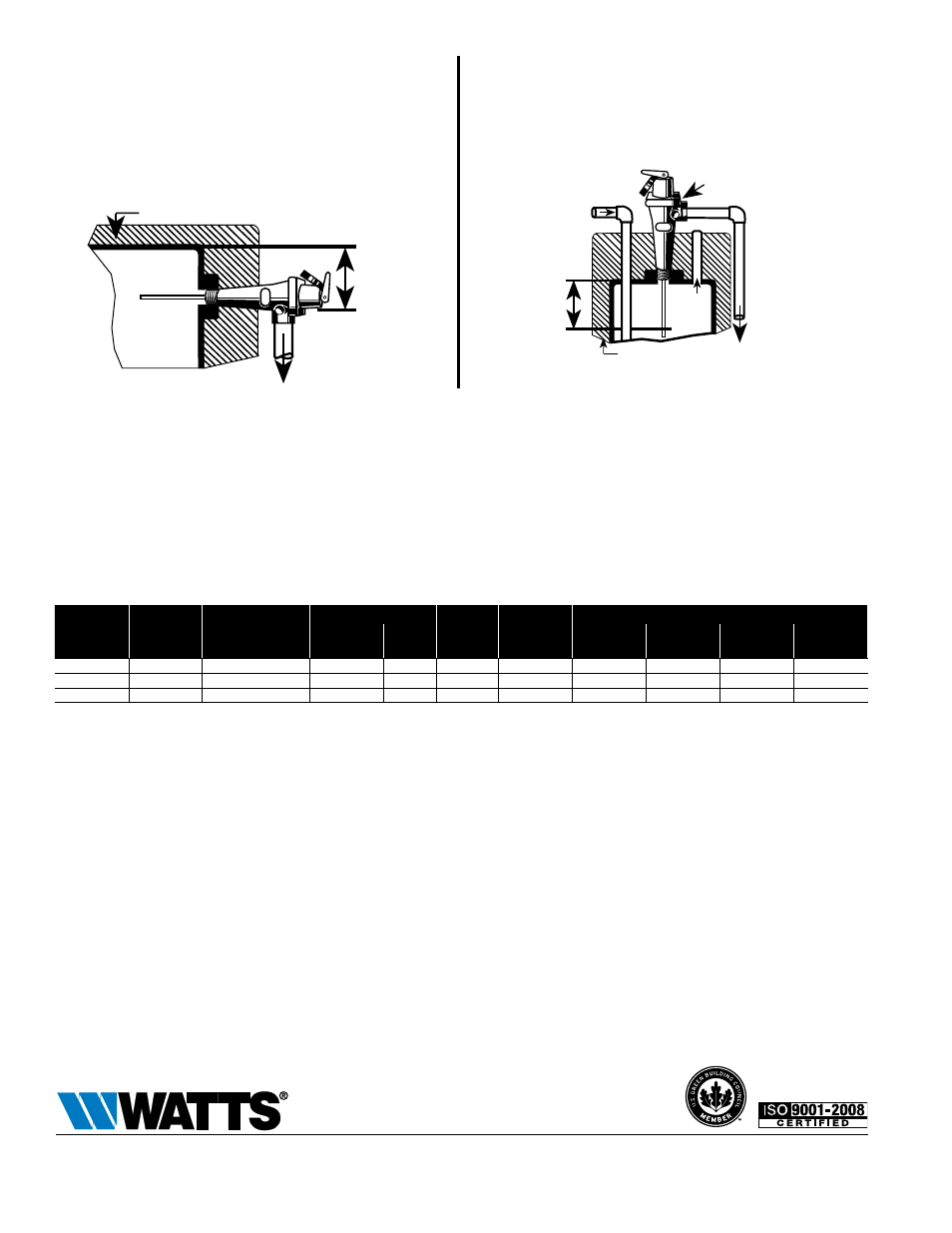

M ax. 6" i nsulatio n, D ischarge line, Direct side tapping – Watts LFLLL40XL User Manual

Page 2: For heaters with direct top tapping, General recommendations, Max. 6" insulation

ES-LFLL/LLL-40XL 1315

© 2013 Watts

USA: Tel: (978) 688-1811 • Fax: (978) 794-1848 • www.watts.com

Canada: Tel: (905) 332-4090 • Fax: (905) 332-7068 • www.watts.ca

A Watts Water Technologies Company

M ax. 6"

I nsulatio n

D ischarge

Line

Discharge Lin

e

Cold

Hot

T&P Relief

Valve

Max.

6"

Insulation

Max. 6"

(152mm)

Direct Side Tapping

For External Flue Heaters

Use extra length extension thermostat to extend into water storage

tank.

For Internal Flue Heaters

Use short or standard length thermostat. Vertical discharge line must

be installed with its direction downward.

For Heaters with Direct Top Tapping

Use standard or extra length extension thermostat.

Max. 6"

(152mm)

General Recommendations

For gas, electric or oil-fired storage water heaters between 180,000 to 205,000 BTU/Hr. rating: Use 3⁄4" (20mm) Series 40 tested under ANSI

Z21.22 with ratings as certified and listed by CSA.

For gas or oil-fired storage water heaters between 205,000 and 500,000 BTU/Hr. rating and for compliance with applicable water heater label-

ing requirements: Use 1" (25mm) 40 Series tested under ANSI Z21.22 with ratings as certified and listed by CSA.

For the full range of high capacity temperature and pressure relief valves Series LF40, LF140, LF240, LF340 and LF342.

See ES-LF40, LF140, LF240, LF340.

ModeL

InLet X

outLet (In.)

therMostat Length

(In.) (BeLow InLet

thread)

dIMensIons (In.)

weIght

LBs.

Csa teMp.

steaM ratIng

Btu/hr

**asMe pressure steaM ratIng Btu/hr

heIght (Less

therMostat)

wIdth

@75psI set

pres.

@100psI set

pres.

@125psI set

pres.

@150psI set

pres.

LFLL40XL

3

⁄

4

M x

3

⁄

4

F

3

1

⁄

2

5

5

⁄

8

2

5

⁄

8

1

1

⁄

2

205,000

777,600

997,600

1,217,600

1,437,600

LFLLL40XL

3

⁄

4

M x

3

⁄

4

F

5

7

5

⁄

8

2

5

⁄

8

2

205,000

777,600

997,600

1,217,600

1,437,600

LFLL40XL

1M x 1F

3

6

1

⁄

2

2

3

⁄

4

2

500,000

1,155,000

1,481,000

1,808,000

2,134,000

M= Male

F=Female

**ASME capacities are steam pressure ratings and do not reflect the CSA temperature relieving capacity of the valves for selection purposes.

Temperature and Pressure Relief Valves should be inspected AT LEAST ONCE EVERY TWO TO FOUR YEARS, and replaced, if necessary, by

a licensed plumbing contractor or qualified service technician, to ensure that the product has not been affected by corrosive water conditions

and to ensure that the valve and discharge line have not been altered or tampered with illegally. Certain naturally occurring conditions may cor-

rode the valve or its components over time, rendering the valve inoperative. Such conditions can only be detected if the valve and its compo-

nents are physically removed and inspected. Do not attempt to conduct an inspection on your own. Contact your plumbing contractor for a

re-inspection to assure continuing safety.