Watts 757NDCDA User Manual

Double check detector assemblies, For non-health hazard applications

For Non-Health Hazard Applications

ES-757DCDA/757NDCDA

Job Name –––––––––––––––––––––––––––––––––––––––––––

Contractor ––––––––––––––––––––––––––––––––––––––––––––

Job Location –––––––––––––––––––––––––––––––––––––––––

Approval –––––––––––––––––––––––––––––––––––––––––––––

Engineer –––––––––––––––––––––––––––––––––––––––––––––

Contractor’s P.O. No. ––––––––––––––––––––––––––––––––––

Approval –––––––––––––––––––––––––––––––––––––––––––––

Representative ––––––––––––––––––––––––––––––––––––––––

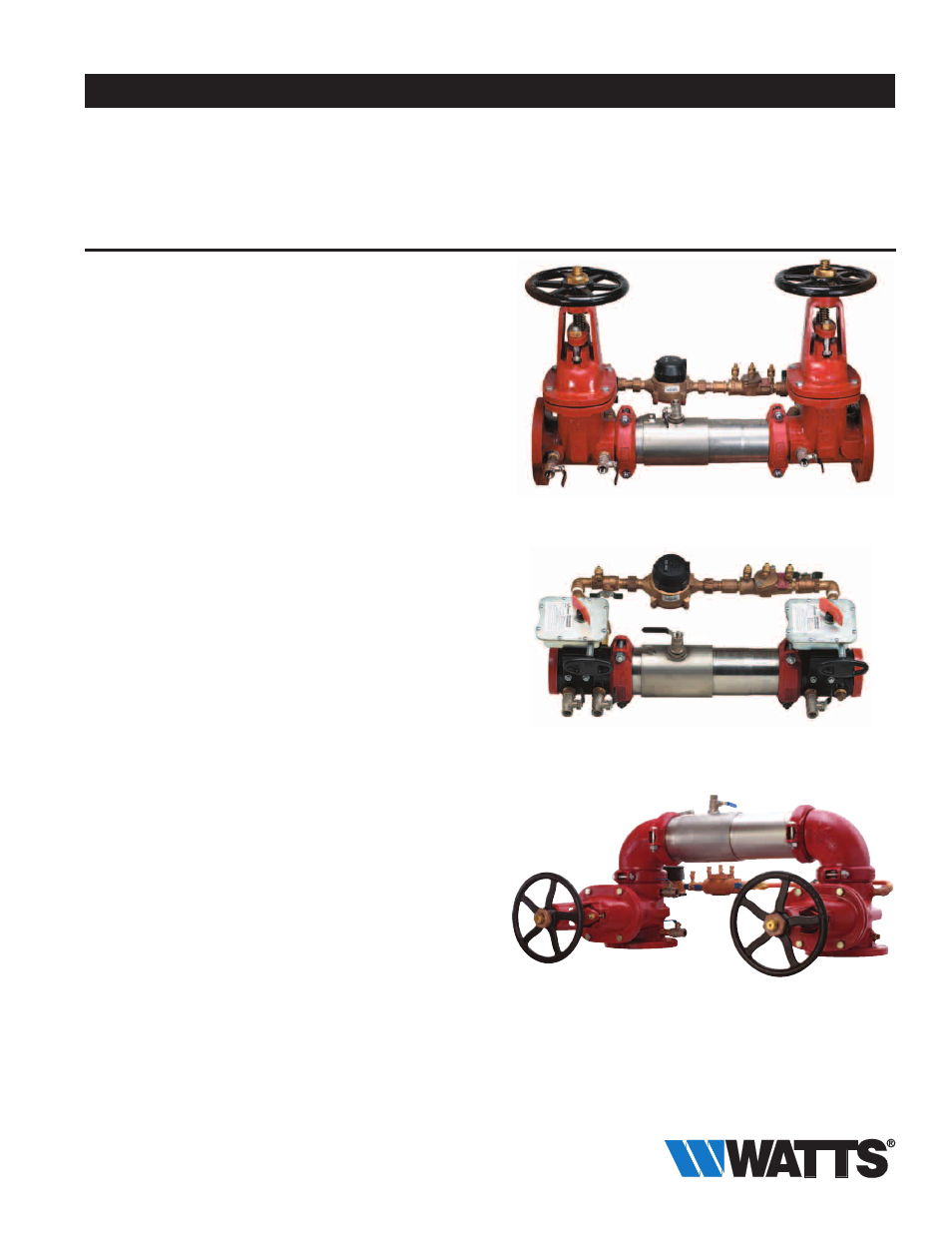

Series 757DCDA,

757NDCDA

Double Check Detector Assemblies

Sizes: 2

1

/

2

" – 10" (65 – 250 mm)

Series 757DCDA, 757NDCDA Double Check Detector

Assemblies are used to prevent backflow of non-health hazard

pollutants that are objectionable but not toxic, from entering

the potable water supply system. The 757DCDA, 757NDCDA

may be installed under continuous pressure service and may

be subjected to backpressure and backsiphonage. Series

757DCDA, 757NDCDA is used primarily on fire line sprinkler

systems when it is necessary to monitor unauthorized use of

water.

Features

• Extremely compact design

• 70% Lighter than traditional designs

• 304 (Schedule 40) stainless steel housing & sleeve

• Groove fittings allow integral pipeline adjustment

• Patented tri-link spring check provides lowest pressure loss

• Unmatched ease of serviceability

• Available with grooved butterfly valve shutoffs

• May be used for horizontal, vertical or N pattern installations

• Replaceable check disc rubber

Specifications

The Double Check Detector Assembly shall consist of two

independent tri-link check modules within a single housing,

sleeve access port, four test cocks and two drip tight shutoff

valves. Tri-link checks shall be removable and serviceable, with-

out the use of special tools. The housing shall be constructed

of 304 Schedule 40 stainless steel pipe with groove end con-

nections. Tri-link checks shall have reversible elastomer discs

and in operation shall produce drip tight closure against reverse

flow caused by backpressure or backsiphonage. The bypass

assembly shall consist of a meter, which registers in either gal-

lon or cubic measurement, a double check backflow assembly

and required test cocks. Assembly shall be a Watts Regulator

Company Series 757DCDA, 757NDCDA.

757DCDAOSY

757NDCDAOSY

757DCDABFG

Watts product specifications in U.S. customary units and metric are approximate and are provided for reference only. For precise measurements,

please contact Watts Technical Service. Watts reserves the right to change or modify product design, construction, specifications, or materials with-

out prior notice and without incurring any obligation to make such changes and modifications on Watts products previously or subsequently sold.