Test procedure, Double check valve assembly, Test check valve no. 1 – Watts 007M1DCDA User Manual

Page 4: Test check valve no. 2, Test for leaky no. 2 shutoff

Printed in U.S.A.

RP/IS-007DCDA 0325

EDP# 1911335

© Watts Regulator Co., 1998

Watts USA website: www.wattsreg.com

Watts Canada website: www.wattscda.com

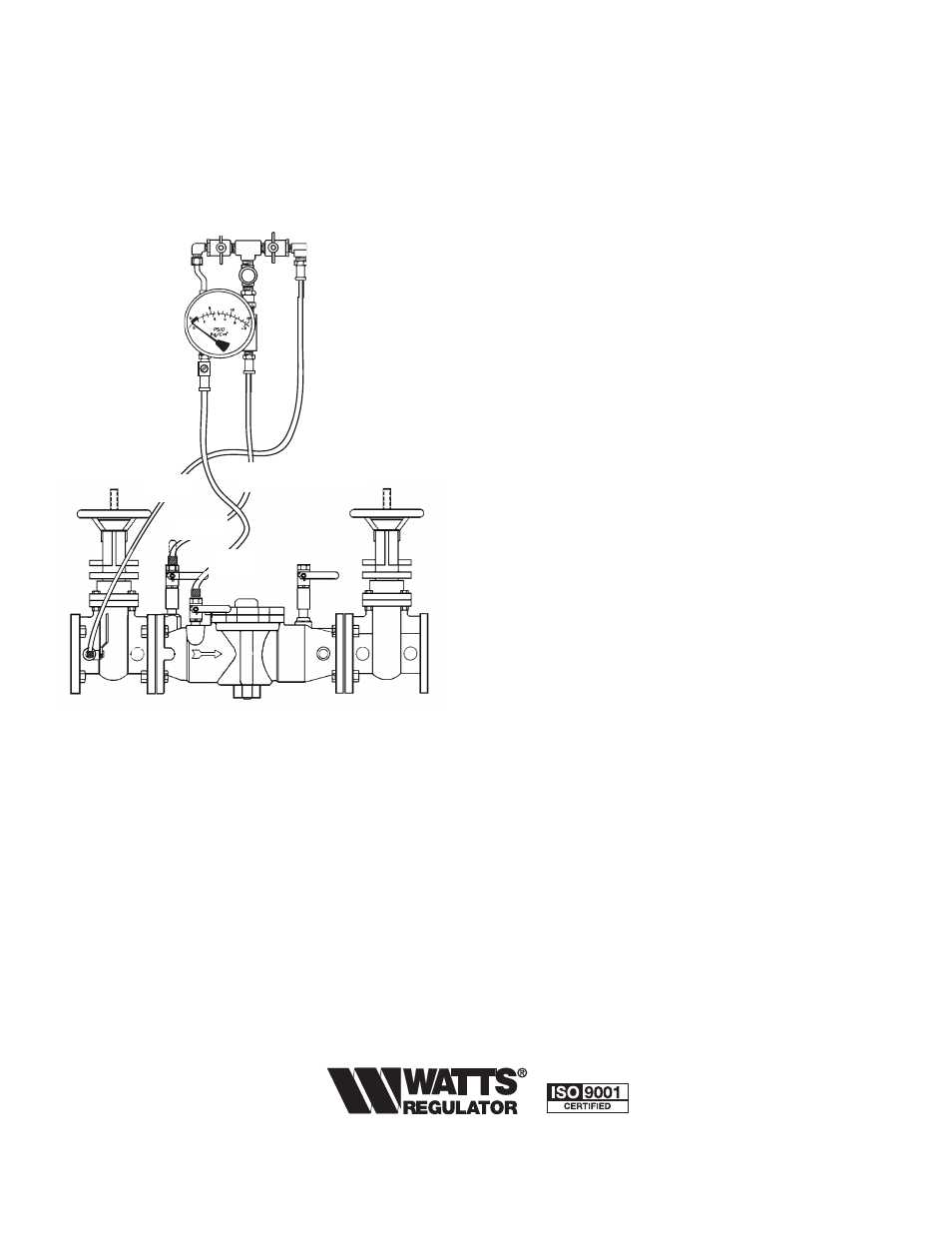

Test Procedure

Double Check Valve Assembly

Test Check Valve No. 1

Step 1: Ensure shutoff #1 is open, shutoff #2 is closed.

Step 2: Connect high side hose to test cock #3, low side to

test cock #2 and open both test cock #2 and test

cock #3.

Step 3: Open valve C, then open A to bleed air from the high

side. Close valve A, then open B to bleed low side.

Close valve B.

Step 4: Connect vent hose loosely to test cock #1. Open

valve A to vent air from vent hose. Tighten vent hose

at test cock #1, open test cock #1.

Step 5: Close shutoff #1. Slowly loosen hose at test cock #2

until differential gauge rises to 2 psi and retighten

hose. If the differential reading does not decrease,

record check valves as “tight”.

Test Check Valve No. 2

Step 1: Move the high side hose to test cock #4, low side to

test cock #3 and open both test cock #3 and test

cock #4. Remove vent hose from test cock #1, open

shutoff #1.

Step 2: Open valve C, then open valve A to bleed air from

the high side. Close valve A, then open valve B to

bleed lowside. Close valve B.

Step 3: Connect vent hose loosely to test cock #1. Open

valve A to vent air from the vent hose. Tighten vent

hose at test cock #1, open test cock #1.

Step 4: Close shutoff #1, then slowly loosen hose at test

cock #3 until differential gauge rises to 2 psi and

retighten hose. If the differential reading does not

decrease, record check as tight. Remove all hoses

and restore valve to original working condition.

Note: The assembly will fail both the first and second

check valve tests above, if shutoff #2 leaks excessively.

To test for a leaky #2 shutoff, use the following procedure.

Test for Leaky No. 2 Shutoff

Step 1: Connect the high side to test cock #1, low side to

test cock #4. Open test cock #1 and test cock #4.

Close shutoffs #1 and #2.

Step 2: Close valve C. Open valve A, then open valve B

1

⁄

2

turn, loosen hose at test cock #4 to remove air.

Retighten hose.

Step 3: If the differential gauge rises above 0, there is exces-

sive leakage at shutoff #2 and it must be replaced to

test the assembly.

Note: Product informaiton is subject to change with-

out notice and supersedes all previous publications.

Ball Type

Test Valves

(B)

Needle

Valve

(A)

Test Cock

No. 1

Test Cock

No. 2

(C)

Vent Hose

(Color - Blue)

Low Hose

(Color - White or Red)

Test Cock

No. 3