Watts FPP-5-975-DOE User Manual

Flow-max, Hp series filter cartridges

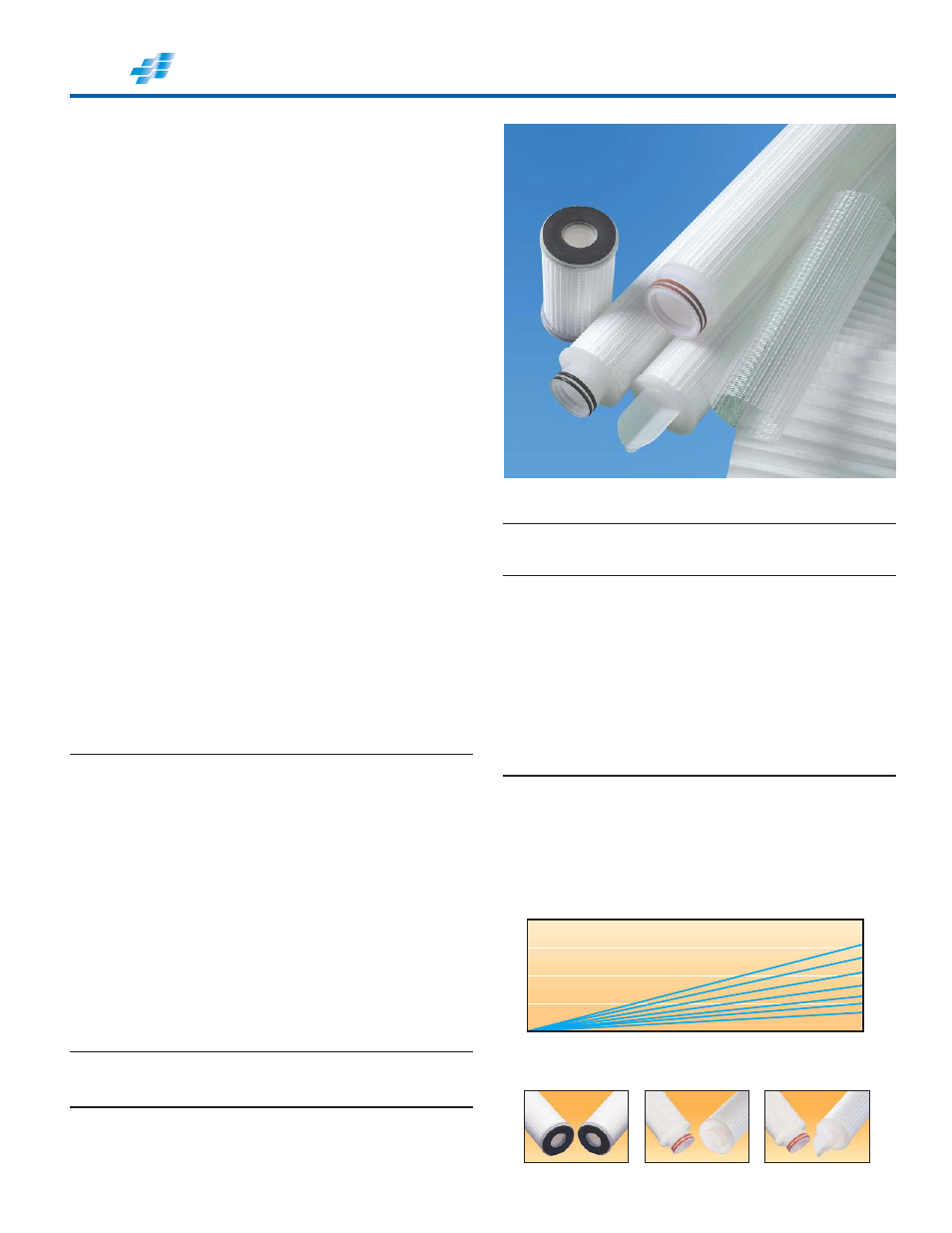

Flow-Max

®

HP Series Filter Cartridges

High efficiency pleated filter cartridges

Flow-Max HP series filter cartridges are cost

effective, disposable, filter elements for a wide

range of applications. Flow-Max HP cartridges

are constructed of highly efficient pleated

polypropylene filter media with extended filter

area to provide high flow rates, low pressure

drop and increased dirt holding capacity.

Features

•

100% polypropylene

•

Ratings from 0.2 to 50 micron

•

FDA listed polypropylene components

•

Removal efficiencies to 99.98%

•

High surface area

•

Long service life & reduced maintenance costs

•

Fixed pore construction for reliability

Application

•

High purity water

•

Chemicals

•

Traps for DI resin

•

Cosmetics

•

Electronics

•

Inks

•

Pre filtration for RO

•

Food & beverage

•

Magnetic tape coatings

•

Bottled water

•

Aqueous solutions

•

Edible oils

•

Plating solutions

•

Waste water

Specifications

Components

Data

Filter media

Polypropylene

End caps

Polypropylene

Center tubes

Polypropylene

Cage

Polypropylene

Gaskets & o-rings

EPDM, standard. (Buna-N,

Viton and Silicone are optional.)

Micron ratings

0.2, 0.45, 1, 2, 5, 10, 25 & 50

Operating temperature 175° F (80° C) maximum

Collapse pressure

130 psid (8.9 bar) maximum

Change out

35 psid (2.4 bar) maximum

FDA

All materials comply with FDA

174.5, 177.1520 & 177.1630

for contact with foods &

beverages

Dimensions

Nominal lengths

4-7/8”, 9-3/4”, 10”, 20”, 30” & 40”

Outside diameter

2.5” (6.35 cm)

Inside diameter

1.0” (2.54 cm)

Filter removal efficiency

Beta ratio

10000

5000

100

50

10

Efficiency

99.99%

99.98%

99%

98%

90%

0.2 micron

0.35

0.2

0.1

----

----

0.45

0.6

0.45

0.3

0.2

----

1 micron

1.2

1.0

0.6

0.3

0.25

2 micron

2.5

2.0

1.5

1.0

0.8

5 micron

8.0

5.0

4.0

3.0

2.0

10 micron

13.0

10.0

8.0

7.0

5.0

25 micron

32.0

25.0

19.0

15.0

13.0

50 micron

66.0

50.0

44.0

32.0

26.0

Relative performance data were developed using laboratory tests,

which may be used for guidelines in cartridge selection. The

single-pass test method was used with particle counters and 3

GPM flow per 10” cartridge. Results vary, and actual field tests

may be necessary to determine final cartridge selection.

1

2

3

4

5

6

7

8

9

10

5

4

3

2

1

Micron

0.2

0.45

1

5

10

25

50

Gallons Per Minute

P.

S

. I.

DOE

222 or 226 / Flat

222 or 226 / Fin

Initial pressure drop per 10” cartridge