Watts 994RPDA User Manual

Series 994rpda, Reduced pressure detector assem- blies, For health hazard applications

For Health Hazard Applications

ES-994RPDA

Job Name –––––––––––––––––––––––––––––––––––––––––––– Contractor

––––––––––––––––––––––––––––––––––––––––––––

Job Location –––––––––––––––––––––––––––––––––––––––––– Approval

––––––––––––––––––––––––––––––––––––––––––––––

Engineer –––––––––––––––––––––––––––––––––––––––––––––

Contractor’s P.O. No. –––––––––––––––––––––––––––––––––––

Approval ––––––––––––––––––––––––––––––––––––––––––––– Representative

–––––––––––––––––––––––––––––––––––––––––

994RPDAOSY

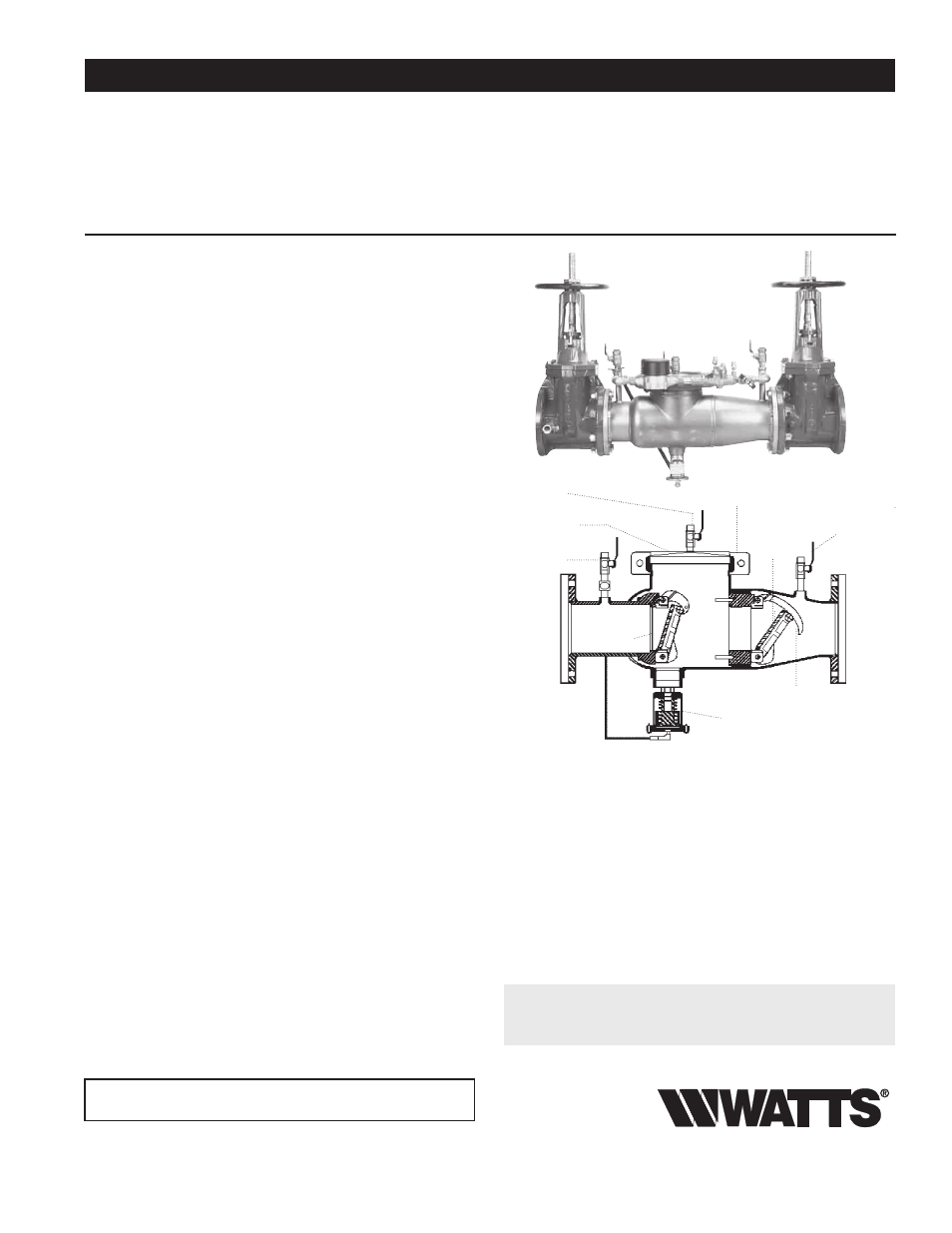

Series 994RPDA

Reduced Pressure Detector Assem-

blies

Sizes 2

1

⁄

2

" – 6" (65 – 150mm)

Series 994RPDA Reduced Pressure Detector Assemblies are designed for use in

accordance with water authority-containment programs. This series is normally used

in health hazard applications to protect against backsiphonage and backpressure. This

series can be used to prevent the reverse flow of fire protection substances, i.e.,

glycerin wetting agents, foam agents, stagnant water, auxiliary supplies and water of

non-potable quality from being pumped or siphoned into the potable water supply.

Features

• Stainless steel construction provides long term corrosion resistance and

maximum strength

• Stainless steel body is half the weight of competitive designs reducing

installation and shipping costs

• Short end to end dimensions makes retrofit easy

• Bottom mounted relief valve reduces clearance requirements when installed

against an outside wall

• Torsion spring check valves provides maximum flow at low pressure drop

• Thermoplastic & stainless steel check valves for trouble-free operation

• No special tools required for servicing

• Compact construction allows for smaller enclosures

• Stainless steel relief valve features a balanced rolling diaphragm to

eliminate sliding seals and lower maintenance costs

• Detects underground leaks and unauthorized water use.

• GPM or CFM meter available

Specifications

A Reduced Pressure Detector Assembly shall be installed at each cross-connection

to prevent backsiphonage and backpressure of hazardous materials into the potable

water supply. The assembly shall consist of a pressure differential relief valve located

in a zone between two positive seating check valves. The main valve body shall be

manufactured from 300 Series stainless steel for corrosion resistance. The check

valves shall be of thermoplastic construction with stainless steel hinge pins, cam

arm, and cam bearing. The check valve shall utilize a single torsion spring design to

minimize pressure drop through the assembly. The check valves shall be modular

and shall seal to the main valve body by the use of an O-ring. There shall be no

brass or bronze parts used within the check assembly or relief valve. The use of seat

screws to retain the check valve seat is prohibited. All internal parts shall be accessible

through a single cover on the valve assembly securely held in place by a two-bolt

grooved coupling. The differential relief valve shall be of stainless steel construction

and shall utilize a rolling diaphragm and no sliding seals. The relief valve shall be

bottom mounted and supplied with a steel reinforced sensing hose. The assembly

shall include two resilient shutoff valves and four ball type test cocks and a hydrauli-

cally balanced bypass line. The bypass line shall include a meter, small diameter

reduced pressure zone assembly and isolation valves. The bypass reduced pressure

assembly shall have a single bolted on cover and top mounted test cocks. The as-

sembly shall be a Watts Series 994RPDA.

IMPORTANT: INQUIRE WITH GOVERNING AUTHORITIES

FOR LOCAL INSTALLATION REQUIREMENTS

Now Available

WattsBox Insulated Enclosures.

For more information, send for literature ES-WB.

Stainless

Steel Cover

Test Cock

Replaceable

Seat

Test Cock

Grooved Coupling

Test Cock

Disc

Laser Cut/ Polished Cam Arm

Stainless Steel Relief Valve

Models

Suffix:

LF –

without shutoff valves

OSY –

UL/FM outside stem and yoke resilient seated gate valves

*OSY FxG – flanged inlet gate connection and grooved outlet gate connection

*OSY GxF – grooved inlet gate connection and flanged outlet gate connection

*OSY GxG – grooved inlet gate connection and grooved outlet gate connection

CFM –

cubic feet per minute meter

GPM –

gallons per minute meter

Available with grooved NRS gate valves - consult factory*

Post indicator plate and operating nut available - consult factory*

*Consult factory for dimensions

Note: The installation of a drain line is recommended. When installing a drain line,

an air gap is necessary.

Watts product specifications in U.S. customary units and metric are approximate and are provided for reference only. For precise measurements, please contact

Watts Technical Service. Watts reserves the right to change or modify product design, construction, specifications, or materials without prior notice and without

incurring any obligation to make such changes and modifications on Watts products previously or subsequently sold.