Watts DETA User Manual

Series eta and deta, Asme code expansion tank

IS-ETA/DETA

Series ETA and DETA

ASME Code Expansion Tank

Installation Instructions

Warnings

• This Expansion Tank is designed and intended for water storage at maximum pres-

sure and maximum temperature as indicated on the nameplate. Any use other than

for water or at a sustained or instantaneous pressure in excess of listed rating is

UNSAFE and may cause property damage, serious bodily injury or result in death.

• This Expansion Tank, like all Expansion Tanks, may eventually leak. Do not install

without adequate drainage provisions where water flow will cause damage.

• Improper installation, adjustment, alteration, service or maintenance may cause

property damage, serious bodily injury or death. Read instructions completely before

proceeding with installation.

• Only qualified personnel should install or service this equipment in accordance with

local codes and ordinances.

• The manufacturer of this tank does not accept any liability or other responsibility for

personal injury or property damage resulting from improper use, installation or opera-

tion of this tank or the system of which it is a part.

Important!

• A Pressure Relief Valve sized and installed in accordance with Local Codes

must be incorporated in the system. In those systems requiring a combined

Temperature and Pressure Safety Relief Valve, the Temperature and Pressure

Safety Relief Valve should be sized and installed in accordance with Local Codes.

• Never plug a Safety Relief Valve.

1. Prior to beginning installation, visually inspect the tank for damage which may have

occurred during transit.

2. Determine the system pressure.

3. Prior to installation of the tank in the system the tank must be pre-charged to the

system pressure as determined in Step 2.

To pre-charge tank:

A. Remove pipe plug covering the valve enclosure.

B. Check and adjust the charge by adding or releasing air (Oil and water free com-

pressed air or nitrogen gas may be used.)

C. After adjusting air pressure, test air valve for leakage, (Shcrader type tire valve

core may be used for replacement.)

D. Replace pipe plug.

4. Set tank in place and connect system piping using isolation valve(s) and drain.

Caution: Do not loosen nuts on cover plate - This will result in loss of pre-charge. Cover

plate must not be removed until the air pressure in the tank has been bleed to zero

gauge pressure. (Model ET-RA only)

5. Purge air from system prior to placing tank into operation. When filling the system

with water, open valves to tank to ensure any water or air remaining in the bladder

from factory testing is displaced prior to placing the tank in operation.

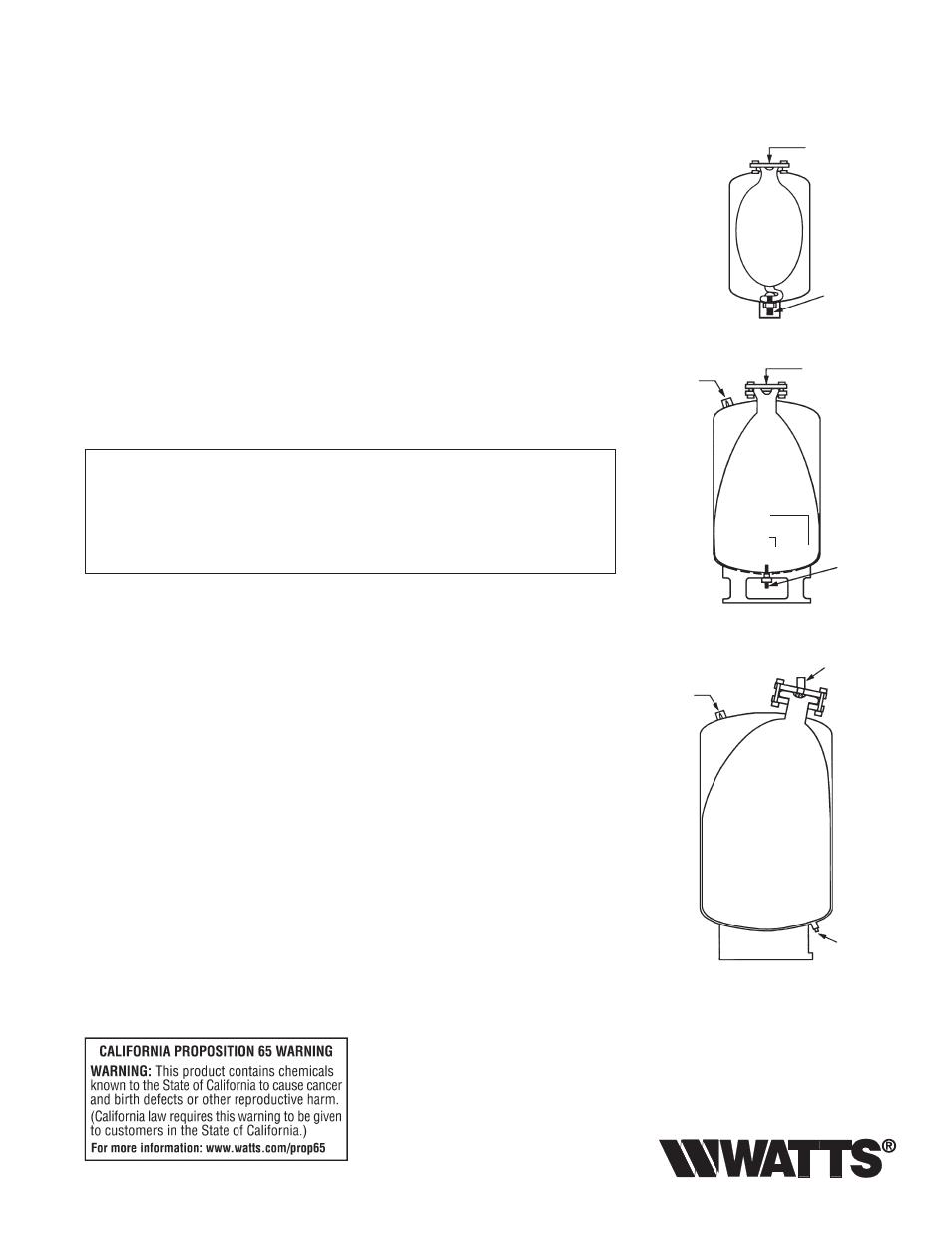

Note: Model ET-RA 85 through 800 - These tanks have both top and bottom access to

the bladder. It is recommended that only the bottom connection be used for connec-

tion to the system. Top connections may be used for gauges, relief valves, etc.

6. Any connection not used must be plugged and checked for leakage.

Air Charging

Valve

System

Connection

Air Charging

Valve

System

Connection

System

Connection

Air Charging

Valve

System

Connection

System

Connection

BLADDER

BLADDER

BLADDER