Watts F518 / F1518 User Manual

Classic series basic valves, Standard materials, Operating pressure

Classic Series Basic Valves

Job Name –––––––––––––––––––––––––––––––––––––––––––

Contractor ––––––––––––––––––––––––––––––––––––––––––––

Job Location –––––––––––––––––––––––––––––––––––––––––

Approval –––––––––––––––––––––––––––––––––––––––––––––

Engineer –––––––––––––––––––––––––––––––––––––––––––––

Contractor’s P.O. No. ––––––––––––––––––––––––––––––––––

Approval –––––––––––––––––––––––––––––––––––––––––––––

Representative ––––––––––––––––––––––––––––––––––––––––

Viton

®

is a registered trademark of DuPont Dow Elastomers.

Watts product specifications in U.S. customary units and metric are approximate and are provided for reference only. For precise measurements,

please contact Watts Technical Service. Watts reserves the right to change or modify product design, construction, specifications, or materials with-

out prior notice and without incurring any obligation to make such changes and modifications on Watts products previously or subsequently sold.

ES-ACV-F518-F1518

Standard Materials

Body & Cover:

Ductile Iron ASTM A536

Coating:

NSF Listed Fusion Bonded Epoxy Lined and

Coated

Trim:

316 Stainless Steel 2" – 8" (50 – 200mm)

ASTM B62 Bronze 10" – 16" (250 – 400mm)

(Stainless Steel Optional)

Elastomers:

Buna-N (standard)

EPDM (optional)

Viton

®

(optional)

Stem, Nut & Spring: Stainless Steel

Operating Pressure

Threaded = 400psi (27.6 bar)

150 Flanged = 250psi (17.2 bar)

300 Flanged = 400psi (27.6 bar)

Operating Temperature

Buna-N: 160°F (71°C) Maximum

EPDM: 300°F (140°C) Maximum

Viton

®

: 250°F (121°C) Maximum

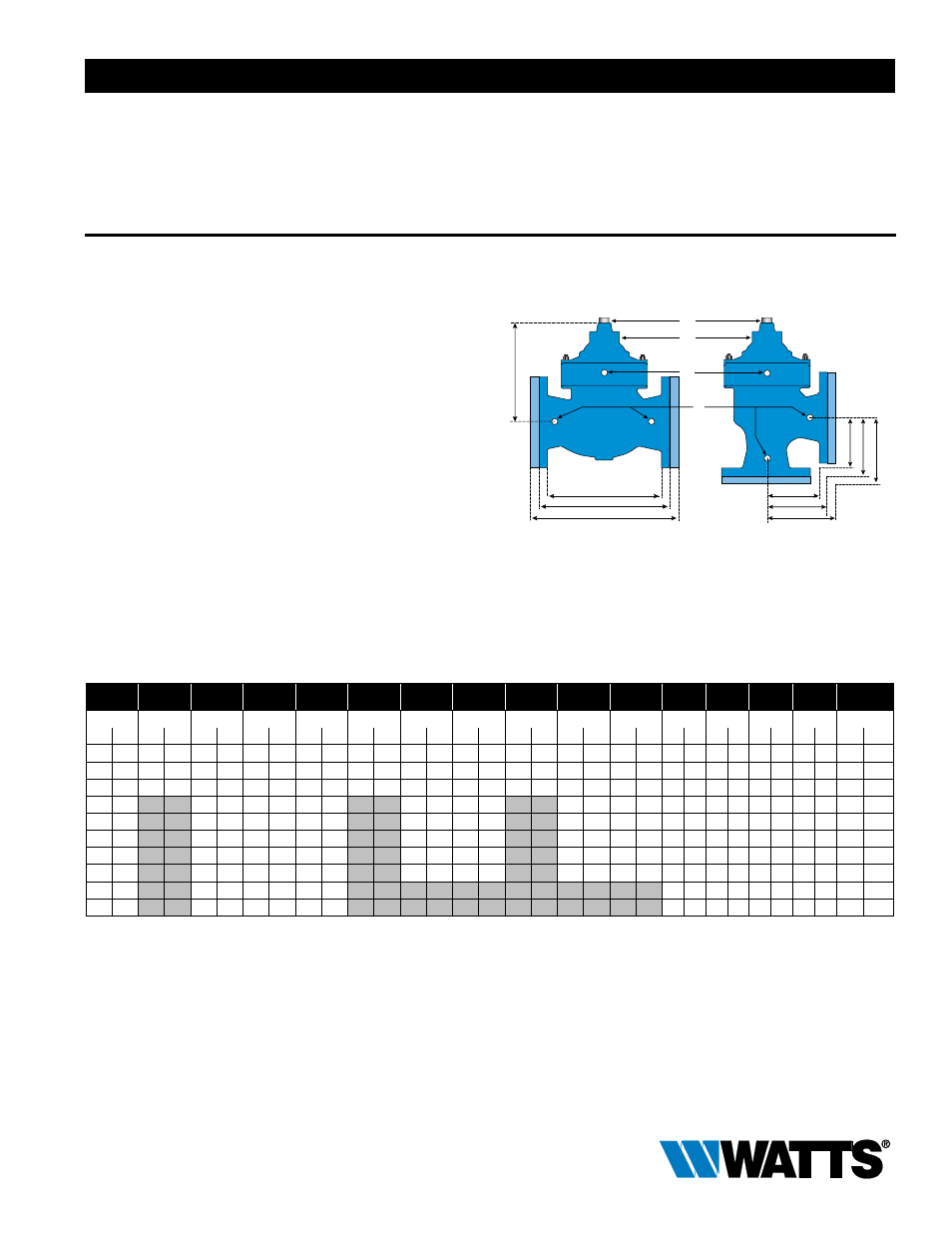

F518 (Globe)

F1518 (Angle)

K

A

B

C

E

F

G

H I

J

D

L

M

N

F518 / F1518

Full Port Ductile Iron

Dual Chamber Basic Valve with

Mechanical Check Feature

The Watts ACV Models F518 and F1518 are full port, dual

chamber basic valves that incorporate a two-piece telescoping

disc and diaphragm assembly. This assembly is the only moving

part within the valve, allowing it to open or close as commanded

by the pilot control system. The lower portion of this two-piece

assembly is a mechanical check feature, which acts indepen-

dent of diaphragm position or pilot control system, and provides

immediate check action when flow ceases.

When pressure is applied to the upper diaphragm chamber and

released from the lower diaphragm chamber, the valve travels

to a closed position. When pressure is applied to the lower dia-

phragm chamber and released from the upper diaphragm cham-

ber the valve travels to a full open position.

Model F518: Globe Pattern Dual Chamber Basic Valve with

Mechanical Check Feature.

Model F1518: Angle Pattern Dual Chamber Basic Valve with

Mechanical Check Feature.

Dimensions

Valve Size

Globe

Thread

Globe 150# Globe 300# Cover To

Center

Angle

Thread

Angle 150# Angle 300#

Angle

Thread

Angle 150# Angle 300# Port Size Port Size Port Size Port Size

Shipping

Weights*

A

B

C

D

E

F

G

H

I

J

K

L

M

N

in. mm in. mm in. mm in. mm in. mm in. mm in. mm in. mm in. mm in. mm in. mm in. mm in. mm in. mm in. mm lbs. kgs.

2

50

9

3

⁄

8

238 9

3

⁄

8

238

10

254 6

3

⁄

8

162

4

102

4

102 4

1

⁄

4

108

4

102

4

102 4

1

⁄

4

108

1

⁄

2

13

1

⁄

2

13

1

⁄

4

6

1

⁄

4

6

40

18

2

1

⁄

2

65

11

279

11

279 11

5

⁄

8

295 8

1

⁄

2

216 5

1

⁄

2

140 5

1

⁄

2

140 5

13

⁄

16

148

4

102

4

102 4

5

⁄

16

110

1

⁄

2

13

1

⁄

2

13

3

⁄

8

10

1

⁄

4

6

70

32

3

80 10

1

⁄

2

267

12

305 13

1

⁄

4

337 8

3

⁄

4

222 5

1

⁄

4

133 5

3

⁄

4

146 6

1

⁄

8

156 5

1

⁄

4

133 5

3

⁄

4

146 6

1

⁄

8

156

1

⁄

2

13

1

⁄

2

13

3

⁄

8

10

1

⁄

4

6

105

48

4

100

15

381 15

5

⁄

8

397 10

1

⁄

4

260

6

3

⁄

4

171 7

1

⁄

8

181

6

3

⁄

4

171 7

1

⁄

8

181

1

⁄

2

13

1

⁄

2

13

3

⁄

8

10

1

⁄

4

6

230

104

6

150

20

508

21

533

14

356

8

1

⁄

2

216 8

7

⁄

8

225

8

1

⁄

2

216 8

7

⁄

8

225

1

⁄

2

13

1

⁄

2

13

1

⁄

2

13

1

⁄

2

13 375

170

8

200

25

3

⁄

8

645 26

3

⁄

8

670 19

1

⁄

2

495

11

279 11

1

⁄

2

292

11

279 11

1

⁄

2

292

1

⁄

2

13

1

25

1

⁄

2

13

3

⁄

4

19 800

363

10

250

29

3

⁄

4

756 31

1

⁄

8

791 22

1

⁄

2

572

14

7

⁄

8

378 15

5

⁄

8

397

14

7

⁄

8

378 15

5

⁄

8

397

1

25

1

25

1

25

3

⁄

4

19 1100 499

12

300

34 864 35

1

⁄

2

902 24

3

⁄

4

629

17

432 17

3

⁄

4

451

17

432 17

3

⁄

4

451

1

25

1

25

1

25

1

25 1720 780

14

350

39 991 40

1

⁄

2

1029 26

660

1

25

1

25

1

25

1

25 2600 1179

16

400

41

3

⁄

8

1051 43

1

⁄

2

1105 30

1

⁄

2

775

1

25

1

25

1

25

1

25 3300 1497

*Estimated in lbs.