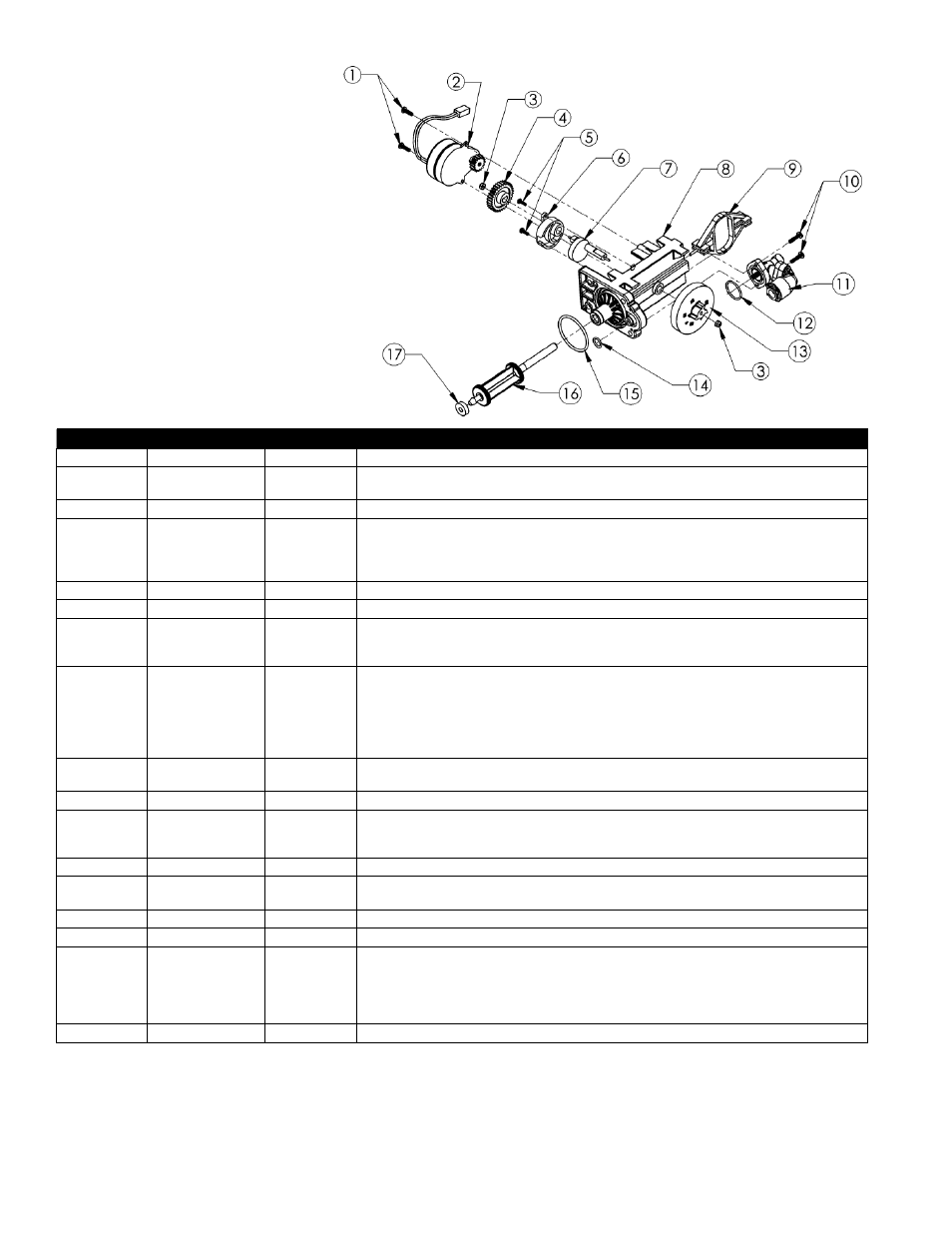

Parts diagrams, Brine valve housing assembly – Watts PWSCAB30K User Manual

Page 14

14

Note: This assembly does not

include a magnet disk or drive

motor and must be ordered

separately.

Item #

Item

QtY.

DescrIptIon

1

Screw

Secures motor to endcap assembly.

2

Drive Motor - 12V

The Drive Motor is held in place by two

1

⁄

2

" screws. The screws should be “snug.” The brass pinion gear on the Motor

should engage the plastic Drive Gear. The wires should be securely fastened to the Control.

3

1

⁄

4

" Hex Nut

Secures drive gear and magnet disc to end cap assembly.

4

Drive Gear

The Drive Gear is assembled to the Piston Slide Cam by means of a “keyed” opening which transfers the “torque”

generated by the Drive Motor to the rest of the drive system. If the drive system becomes jammed, this opening can

become “rounded” causing the gear to turn, but not the Piston Slide Cam. If this occurs, clear the jam and replace the

Drive Gear and Piston Slide Cam (Part No. 93217).

5

Screw

6

Piston Slide Cam Cover

The cover secures the Piston Slide Cam (93217) in place and acts as a bushing for the Cam Shaft.

7

Piston Slide Cam

This is the “heart” of the drive system. There is a threaded stainless steel shaft that runs through the main drive axle.

The Drive Gear is attached at the short end and the Magnet Disc at the other end. The Piston Slide Cam is assembled

inside of the Piston Slide (93216). This Cam Shaft should turn freely before the Motor is assembled.

8

Drive End Cap

1

Seals the two openings on the Main Valve Body. The larger diameter opening is sealed with an O-ring used as an axial

or “face” seal. The O-ring sits in a groove in the End Cap. This groove must be free of defects such as pits or

scratches and also free of debris. The smaller diameter seal is accomplished with an O-ring used as a radial seal. The

O-ring should be placed on the male boss on the End Cap. When assembling the Drain End Cap to the Main Valve Body,

care should be taken to make sure the small O-ring is aligned with the opening in the Main Valve Body and that the

large O-ring stays in the groove in the Drive End Cap. If misaligned, the O-rings can become pinched and leak.

9

Piston Slide

1

The Piston Slide should move freely inside the Drive End Cap Housing.

The stainless steel threaded stud should be pointing toward the Main Valve Body.

10

Screw

2

Secures brine valve to drive endcap assembly.

11

Brine Valve Housing

Assembly

1

Attaches to the Drive End Cap with two

3

⁄

4

" thread cutting screws and has one O-ring seal. When assembling, the O-ring

should be placed on the Drive End Cap boss and be lubricated with silicone grease. A twisting action should be applied

along with pressure until the O-ring seats. (See Brine Valve Assembly sheet for more details.)

12

O-ring

1

Seals the brine valve to the drive endcap.

13

Magnet Disk

Assembly

1

The Magnetic Disc is assembled to the Piston Slide Cam by means of a “keyed” opening to ensure proper orientation.

The magnet in the Magnetic Disc should be flush with the disc surface.

14

O-ring

1

Seals large opening between valve body and drive endcap.

15

O-ring

1

Seals small opening between valve body and drive endcap.

16

Piston Assembly

1

The Piston should be screwed onto the Piston Slide Cam until it “bottoms out,” but care should be taken not to over-

tighten. Overtightening can cause the Piston to break. The white Teflon Hydro-slide O-ring covers should be free of

defects such as indentations and cuts. The Drain Gasket should slide - there will be some friction - without binding on

the Piston shaft. When assembling, care should be taken to insert the Piston into the Main Valve Body without excessive

side-to-side or up/down motion.

17

Drain Gasket

1

Seals the drain end cap when valve is in service position to prevent water flow to drain.

Parts Diagrams

Brine Valve Housing Assembly

Figure 15